Simple, fast, order-related and operator-independent way to measure, test and manage tools

Who is not familiar with this from his own production operation - that search for the right tools for the job! Where are the tools, and are they available as a complete set or as individual components? Cumbersome tool lists that usually cannot be called up on screen when and where they are needed! No clear annotation

on tools for provision at the machine! Tool data are frequently still communicated manually – time-consuming, with great potential for mistakes to be made – at times of ultra-modern, IT-controlled production technologies this is not a cost-effective way of doing things. Because while large sums are being invested in high-tech machines and in ever greater numbers of tools, technically obsolete production operations tend to slip from the field of view – and the vast potential for improving efficiency, and through that to cut down on cost, all inherent in the modernization of procedures of this kind, all too often fails to get the recognition it merits.

This then gives rise to high and non-verifiable costs for tools and their accessories, long periods of machine downtime and, through that, high tooling costs.

Low cost - big impact

It can however all be much simpler, reliable and less costly to implement than it might at first glance appear to be. Here, ZOLLER offers highly-efficient solutions at

low cost – and can also do so for small and medium-sized enterprises.

The individual steps from the acquisition of tools to the provision of tools and to their use on the machine are all based on a simple process which can be organized

simply and better with the help of an intelligent Tool Management system.

Reliable tool flow

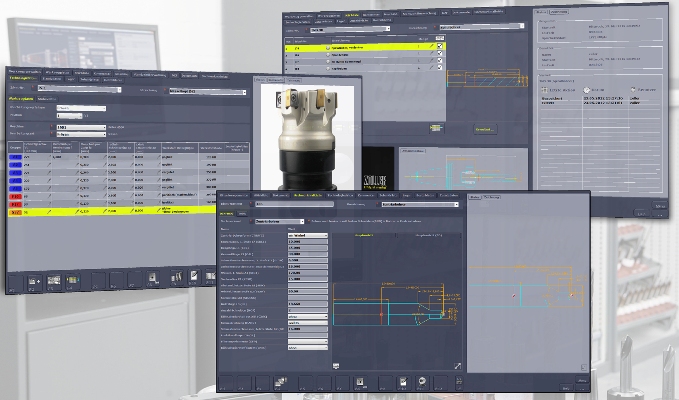

Intelligent software modules such as the ZOLLER tool data management, inventory location management and NC program management systems can guarantee,

when used in conjunction with a ZOLLER measuring machine equipped with »pilot 3.0« image processing, a simple and reliable flow of tools at the workplace.

ZOLLER software modules Technology Data and Technical Features for an intelligent flow of tools

The existing CAD/CAM system produces the NC program and, if necessary, performs tool collision detection. From this, the tool list (setting sheet) can be produced.

Then, using the ZOLLER measuring machine with »pilot 3.0«, the order-specific tools can be measured, checked and managed.

Simply better organized

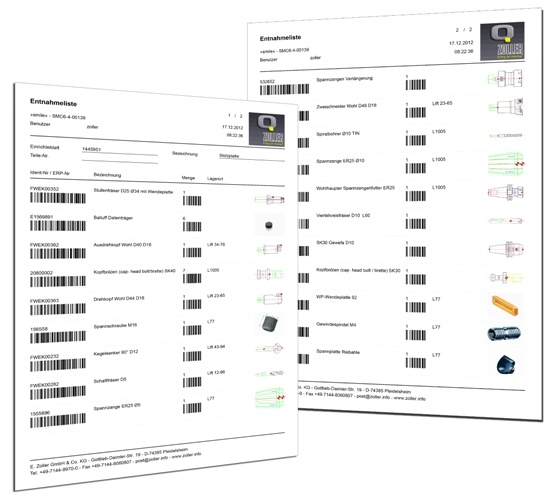

The resultant tool list includes all the information required about tool, machine and workpiece. The tool data are not communicated as they were previously using job progress cards or folders, but instead travel quickly and securely across the modern network. Meaning that they can be called up wherever they are required.

By means of the ZOLLER tool data and inventory location management functions, the complete tools or individual components needed can then be checked out and commissioned. The operator can also print out the commission list actually required for a given job.

Quite simply better organized: tool-based production organization with a ZOLLER measuring device

plus Tool Management Solutions

Vast potential for cost-savings

The storage of tools as individual components offers vast potential for cost savings because expensive tools and accessories do not need to be available on multiple occasions in the form of complete tools. It is possible to gain a quick overview of the tools in circulation and the use to which tools are being put – on the machine,

or with reference to a given job.

Production process that is faster and more independent of the operator

The subsequent measuring and testing or inspection of tools is then a fully automated or a manual process. Data output - in an appropriate format for the control unit -

is transmitted into the customer network at the touch of a button. Keying errors of the kind that can result through manual input on a machine control unit are therefore eliminated. And the laborious task of attaching adhesive labels also becomes a thing of the past.

A cost-effective organizational aid which delivers a big impact is the use of barcodes on existing setting sheets or on the commission list. This makes it possible to

produce complete tools from individual components quickly and easily, or to track down existing complete tools.

Fast and transparent recording of tool data via the commission list

Also for small to medium-sized enterprises (SMEs)

This operation is already possible with a ZOLLER »smile400/pilot 3.0«. It does not always have to be the complete solution – depending on which vertically integrated aspect of production needs to be optimized, this modular software can be implemented in a series of small steps and to any desired extent. ZOLLER TMS Tool Management Solutions are grouped together in three packages, Bronze, Silver and Gold, and deliver transparency to the tool-based production organization. Users can always access the correct data in the tool flow. Simply better organized at every stage of the production operation.

Barcode scanner for fast and reliable retrieval of data

Pictures: ZOLLER

Germany

Germany