expect great measures

ZOLLER opens up new dimensions

With its expanded product range of solutions for the measurement and organization of cutting tools, ZOLLER opens up new dimensions –

according to the show motto 2013: Maximum Dimension.

A maximum of economic viability, maximum efficiency, maximum precision and leading operating technology – those are the fundamental characteristics of ZOLLER products. This years innovations presented at EMO 2013 in hall 3, booth F-25 are furthermore connected by one shared data base guaranteeing a transparent flow of all tool data throughout the entire manufacturing process.

New!: Product Area Tool Presetting and Measuring

Maximum user friendliness: the new »smile / pilot 2 mT«

ZOLLER’s success series »smile« has been continuously developed further and expanded by a new dimension. The „hot off the griddle“ new presetting and measuring machine »smile/pilot 2 mT« is being introduced to the public for the first time at EMO 2013. It excites with its compact built and the modern, sophisticated yet easy to use operating technology ZOLLER »myTouch«. “This new operating technology sets new standards in its simple and intuitive operation”, so president and owner

Christoph Zoller. In addition, a newly designed tool holder spindle makes power-operated clamping possible even in for this low-budget entry level.

The new »smile / pilot 2 mT« excites with its compact built

and the modern operating technology ZOLLER »myTouch«.

Maximum efficiency for the automotive industry

Special requirements for custom tools used in the automotive industry are being solved with ZOLLER’s second generation »gemini 2« and »aralon 2«. While ZOLLER

has been offering tool presetting and measuring machines for standard tools such as drills, reamers, turning tools or milling heads for years, even disc cutters with inside cutting edges can now be measured precise and fully automatic.

And the new specialist »reamCheck« has an additional integrated electronic probe enabling tactile presetting and measuring of single-blade reamers. Concentricity and run-out can be measured axial as well as radial.

New!: Product Area Tool-Management

Maximum organization: new functionalities for ZOLLER TMS Tool Management Solutions

„Not just measuring solutions, but also the use of cutting tools and their organization is in demand for greater efficiency and more flexibility. The key to an efficient tool usage and therefore optimized tool life as well as an economic manufacturing process is the introduction of a professional tool management system. The still un-known and un-used potential for cost savings in this area is enormous in many businesses”, explains president and owner Alexander Zoller.

The well-established TMS Tool Management Solutions packages BRONZE, SILVER and GOLD were perfected with new functionalities such as the re-grinding module »cetus 2.0« for the coordination of grinding cycles and incoming goods inspection.

In daily presentations with KROMI LogistikAG and CAM-partners, ZOLLER shows live at EMO how a professional tool management system can benefit the entire manufacturing process.

»cetus 2.0«: ZOLLER TMS Tool Management Solutions -

module for the optimization of tool demand

New!: Product Area Tool Inspection

New cutting tools, new materials and new machining technologies require innovative solutions in the area of tool inspection. A think tank and always in close contacts

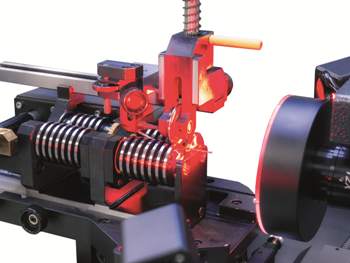

with its customers, ZOLLER has developed a wide variety of job-shop capable products. At EMO, ZOLLER not only presents its successful universal inspection machines »genius« and «smarTcheck« but also new developments in the »pom-« series as well as the completely new designed »threadCheck« and »3dCheck«.

New possibilities for tool manufacturer, grinding and sharpening businesses

With the newly designed »threadCheck«, ZOLLER offers the world-wide only and unique inspection machine to measure helical tools (especially taps or hob cutters) with image processing technology distortion-free and micron- precise.

And the »3dCheck« is a new six-axis CNC-operated machine for the three-dimensional digitalization of work pieces. A target-performance comparison with a CAD model

or a pre-scanned tool is now an easy and fast task.

Maximum production proximity: new developments in the process-oriented »pom-« series

The new vertical »pomDiaCheck« is the ideal solution for fast and process-oriented measurements of 1 micron or less. Specifically diameter on rounded green bodies or drill/reamer tools can be measured with extreme precision.

»pomBasicMicro«The compact tool inspection unit for job-shop applications right next to the grinding machine is now also available with a high resolution camera for micron tools.

»pomBasicMicro« : High resolution camera for micron tools

New!: Automation Solutions

A new dimension in automation: »roboSet« and laser engraving

ZOLLER’s automation solution »roboSet« in combination with a CNC-operated tool presetter is of special interest for all companies with high tooling throughput levels

such as tool manufacturer and grinding businesses as well as in quality assurance. »roboSet« loads the ZOLLER presetter fully automatic and un-manned, 24 hours a day,

7 days a week.

This fully automatic solution for the tool inspection is available in combination with an automatic engraving option of the tool shank. Various parameter can be written right onto the tool after the measuring process.

The »roboSet« will not only be shown in combination with the »genius 3« inspection machine, but also with ZOLLER’s heat-shrink machine »redomatic« for a fully automatic shrinking of tools to nominal value.

Outlook into the next dimension of tool data organization: ZOLLER data base on the show booth

At EMO 2013, ZOLLER presents innovations in the product areas of tool presetting and measuring, tool inspection, tool management and automation solutions on over

400 square meters of booth space. The oversized reproduction of the ZOLLER data base symbolically connects all product areas with the help of fluorescent tubes thus illustrating the future of modern tool management systems in the manufacturing process. All relevant data becomes accessible via the “tool cloud” – anytime and anywhere.

Visit our stand at hall 3, booth F25!

Daily presentations of our CAM Interfaces and on professional toolmanagement!