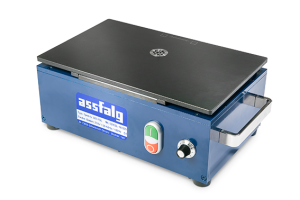

Assfalg

Products

Assfalg GmbH

Deburring and edge milling machines; stationary

ASO 600-ASL

68674

The small, compact deburring machine mills or rounds edges precisely, safely and with ease.

It leaves chatter-free chamfers and radii on angular and round workpieces made of a wide variety of materials. Its universality makes it unique.

Professional advantages:

It leaves chatter-free chamfers and radii on angular and round workpieces made of a wide variety of materials. Its universality makes it unique.

Professional advantages:

- For continuous use with brushless motor

- Tool change within a few seconds

- Zero point clamping

- Extraction socket

- Compact, handy tabletop unit next to the CNC milling- and turning machine

- Precise chamfer adjustment

- Chamfer angle can be changed due to contour cutter with different point angles

- Fast tool change with zero point clamping

- Hardened table with extraction socket

CHP 21 G

|

Deburring and edge milling machine; stationary

Assfalg GmbH

Deburring and edge milling machines; stationary

The CHP 21G automatic bevelling machine is designed for stationary and portable use in weld seam preparation.

The integrated angle adjustment of the CHP 21G allows an easy and individual adjustment of the grinding angle at any time.

Professional Advantages:

The integrated angle adjustment of the CHP 21G allows an easy and individual adjustment of the grinding angle at any time.

Professional Advantages:

- Infinitely adjustable

- Angle adjustment

- Suitable for continuous operation

- High robustness for tough industrial use

- Wheel machining possible from Ø 350 mm

CHP7 | CHP 12

|

Deburring and edge milling machine; stationary

Assfalg GmbH

Deburring and edge milling machines; stationary

The weld edge forming/milling machines shear the edge with the help of a cutting wheel, completely self-propelled, low-noise and low-dust, leaving a rough bevel.

They produce perfect welding edges with the best price-performance ratio.

They can chamfer plates and pipes, including large diameters, as well as small parts and pipes with low thickness.

Professional advantage:

They produce perfect welding edges with the best price-performance ratio.

They can chamfer plates and pipes, including large diameters, as well as small parts and pipes with low thickness.

Professional advantage:

- Automatic feed

- Recommended for machining aluminium

- Portable, light and fast

- Disc machining possible from Ø 350 mm

KKF 4-SL

|

Chamfering Machine for Contours

Assfalg GmbH

Deburring and edge milling machines; stationary

63368

The spindle bearings installed under preload give the KKF 4-SL highly accurate concentricity. Both solid carbide cutters and milling cutters with inserts can be used to achieve excellent tool life. Professional advantages - Big supporting table - Very good concentricity - Continuous operation - Extraction socket - Fast tool change - Wide selection of cutters - Speed regulation - Chamfer angle can be changed due to contour cutter with different point angles Application - Minimum workpiece thickness 1 mm - Can be used for steel, hardened steel, aluminium, brass, copper, plastic, from soft plastic to acrylic glass, wood and much more - Chamfering or rounding of external and internal contours - Automatic feed for bigger workpieces Options - Mobile undercarriage with big rubber rollers - Prism attachment for straight edges - Stop ruler - Guide finger for the use of tapered contour cutters - Extraction device - Automatic feed - Insert milling cutter with guide ball bearing from Ø10mm Delivery contents - Collet wrench - Insert ring with borehole ø 30 mm - Collet ø 6 mm, 8 mm, 10 mm, and 12 mm - Union nut - Operating manual Further accessories can be found in our Accessory Catalogue.

M1 Surfacer

|

Deburring and edge milling machine; stationary

Assfalg GmbH

Deburring and edge milling machines; stationary

The deburring grinding machine is a manually operated, user-friendly deburring machine that is suitable for various machining processes such as grinding, deburring, edge rounding and polishing of metal surfaces.

The swivel arm can rotate 180° and enables the simultaneous mounting of two machining discs. The machine is equipped with a vacuum system that fixes the workpiece on the table.

Professional advantages:

The swivel arm can rotate 180° and enables the simultaneous mounting of two machining discs. The machine is equipped with a vacuum system that fixes the workpiece on the table.

Professional advantages:

- 5 machining processes

- Possible in one machine

- Simultaneous mounting of 2 machining discs

- Machining of several parts possible

- Time-saving disc or brush change

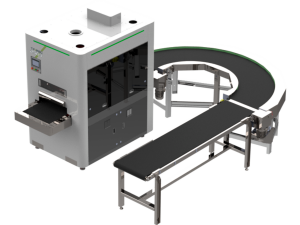

TF Surfacer

|

Deburring and edge milling machine; stationary

Assfalg GmbH

Deburring and edge milling machines; stationary

Our deburring and edge rounding machines type TF enable an optimal Surface Processing up to the perfect surface finish in the dry grinding process.

The Deburring & Edge Rounding Machines are available with 3 different passage widths. They have various performance spectrums, which are individually adapted to the modular principle customizable and configurable to customer requirements.

Both small and large-area sheet metal parts or workpieces can be processed, regardless of the material. These conveyer machines thus show the best possible flexibility in sheet metal processing.

Professional advantages:

The Deburring & Edge Rounding Machines are available with 3 different passage widths. They have various performance spectrums, which are individually adapted to the modular principle customizable and configurable to customer requirements.

Both small and large-area sheet metal parts or workpieces can be processed, regardless of the material. These conveyer machines thus show the best possible flexibility in sheet metal processing.

Professional advantages:

- Different performance spectrums due to individual adaptive modular principle

- Removal of raised burrs and splashes

- Automatic workpiece guidance

- Different material thicknesses can be processed

AF 165

|

Beveling Machine with Sanding Disc

Assfalg GmbH

Deburring and edge milling machines; stationary

19281

Its specialty includes the removal of saw burrs and heavy roughing burrs so that workpieces can be further processed and are safe to use. Fast, cost-effective edge grinding is achieved with long-life flap wheels, CBN or diamond grinding wheels.

Application:

Application:

- Minimum work piece thickness 3 mm

- Can be used for steel, hardened steel, aluminium, brass, copper, plastic, from soft plastic to acrylic glass, wood and much more

- For hardened steel >> CBN-wheels - For carbide metal >> diamond wheels

ASO 160-M | ASO 160-MSL

|

Chamfering Machine with V-prism for Straight Edges

Assfalg GmbH

Deburring and edge milling machines; stationary

35035, 35141

Chamfering thin sheets, solid material or pipe profiles is no challenge for the machines. Whether small parts or bar material, a consistently good surface quality is milled. This makes them indispensable in all metalworking single-part and series production. Professional advantages - Small workpieces can be easily and rapidly worked on by hand - Longer workpieces are chamfered by automatic feed - Consistent high surface quality - Chamfer adjustment by micrometer screw - Speed regulation for the ASO 160-MSL - Easy tool change - V-prsim for ideal guidance of the workpieces - Hardened and ground guide rails - Soft cutting pressure Application - Minimum workpiece thickness of 1 mm - Suitable for steel, max. 1.000 N/mm², aluminum, brass, copper, plastics, from soft plastic to acrylic glass, wood and much more - Deburring workpieces up to welding preparation - For chamfering without rest ridge (cutter edge) Options - Mobile undercarriage with big rubber rollers and integrated swarf drawer - Automatic feed for series production and machining of flat material - V-roller guideways for extending the guide rails Delivery contents - Allen key of 5mm and 6mm - Torx Key T 20 - Aluminum block for machining of faces - Plane cutter head with cutting inserts - Swarf ejection pipe (only with the ASO 160-MSL) - Operating manual Further accessories can be found in our Accessory Catalogue.

ASO 650 | ASO 650-WSL

|

Chamfering Machine with V-prism for Straight Edges

Assfalg GmbH

Deburring and edge milling machines; stationary

10229, 10230

Deburring and chamfering of big workpieces is an easy job. Rounding of edges in use with radius inserts is also possible. Speed control is very useful when processing aluminum or stainless steel.

Professional advantages:

Professional advantages:

- Sturdy cast iron construction with swarf drawer

- Wear-resistant, hardened and ground guide rails

- Precise chamfer adjustment by micrometer screw

- Various cutting inserts to different materials

- Long tool life due to sturdy square cutting inserts and circumferential cut Application

- Minimum workpiece thickness 2mm

- Clean- and burr-free chamfering

- Suitable for sturdy continuous operation

- For preparing welding seams

- For short or thin workpieces below 5 mm, the guide rails must be rotated and used with a 2 mm cutting gap

ASO 850-K

|

Beveling Machine

Assfalg GmbH

Deburring and edge milling machines; stationary

67273

The stable and simple edge milling machine is designed for deburring and edge milling of small to large workpieces from 2mm thickness.

Thanks to the optimized interaction of cutter head and inserts, the machine provides chatter-free, clean and constant chamfering performance up to 3mm x 45° in one cut.

Application:

Thanks to the optimized interaction of cutter head and inserts, the machine provides chatter-free, clean and constant chamfering performance up to 3mm x 45° in one cut.

Application:

- For visually beautiful 45° chamfers

- Universal for robust continuous operation

- Longer tool life due to automatic workpiece feed

- Higher work safety due to automatic workpiece feed

ASO 910

|

Chamfering Machine, selfpropelling

Assfalg GmbH

Deburring and edge milling machines; stationary

64247

The ASO 910 automatic edge milling machine masters the milling of heels or the resetting of claddings with flying colours.

Thanks to its robust version, the machine achieves a chamfer width of up to 50 mm and a chamfer depth of up to 15 mm. The machine is unique in this performance category.

APPLICATION POSSIBILITIES:

Thanks to its robust version, the machine achieves a chamfer width of up to 50 mm and a chamfer depth of up to 15 mm. The machine is unique in this performance category.

APPLICATION POSSIBILITIES:

- Especially suitable for heavy, long and extensive work pieces

- This machine is universal for all materials and suitable for continuous operation

- Shoulder milling or light bevelling at an angle of 90°-75° regarding the perpendicular

- Mobile operation of roller carriage or with crane support or stationary

ASO 930 | ASO 930 Plus

|

Chamfering Machine, selfpropelling

Assfalg GmbH

Deburring and edge milling machines; stationary

60269, 67019

With ASO 930 | ASO 930 Plus it is now possible to mill the front and bottom side of the workpiece.

The workpiece no longer has to be turned. Extremely long tool life is achieved through low-speed (rpm) milling.

Application:

The workpiece no longer has to be turned. Extremely long tool life is achieved through low-speed (rpm) milling.

Application:

- Particularly for heavy, long and large workpieces

- Face- and bottom milling at an angle of 0°-76° with milling width up to 74mm

- Mobile operation of roller carriage or with crane support or stationary

FS 5

|

Beveling Machine with V-Prism

Assfalg GmbH

Deburring and edge milling machines; stationary

41408

The FS 5 is a sturdy and extremely cost-effective chamfering machine with cutter head. Straight edges of cube-shaped workpieces can be easily chamfered. The V-prism is foldable for insert change.

Application:

Application:

- Minimum workpiece thickness 3 mm

- Clean and burr-free chamfering in a section

- Suitable for almost all materials

- Duty cycle approx. 30% / h Features

- Easy handling

- Sturdy guide rails

- Fast change of cutter head and cutting inserts

KKE 1 | KKE 2

|

Beveling Machine for Contours

Assfalg GmbH

Deburring and edge milling machines; stationary

22129, 29642

Straight edges, bores, slotted holes and slots are chamfered precisely, quickly and easily. The prism attachment for machining straight edges rounds off the complete package. They are a great helper at a small price.

Professional advantages:

Professional advantages:

- Ideal for chamfers up to 2mm x 45°

- Internal- and external contours can be chamfered and rounded

- Dimensional accuracy due to ball bearing guide or guide ruler

- No chatter marks

- Very good tool life of the solid carbide cutters

- Compact handy tabletop unit next to the CNC milling- and turning machine

- Precise chamfer adjustment

- Speed control for processing different materials

- Chamfer angle can be changed due to contour cutter with different point angles

- Fast tool change

KKF 3-SL

|

Chamfering Machine for Contours

Assfalg GmbH

Deburring and edge milling machines; stationary

55111

This machine is our most powerful edge and contour milling machine and has the largest worktable. Its robust insert milling cutters are ideal for machining larger and heavier workpieces.

Professional advantages:

Professional advantages:

- Big working table

- Sturdy insert milling cutter

- For continuous operation

- Milling cutter infeed through parallel table adjustment

- Extraction socket

- Precise chamfer adjustment by micrometer screw

- Chamfer angle can be changed by using various insert milling cutters

- Speed regulation Application

- Minimum workpiece thickness 2mm

- Can be used for steel, max. 1.000 N/mm2, aluminum, brass, copper, plastics, from soft plastic to acrylic glass, wood and much more

- Chamfering or rounding of external and internal contours

Speedy Contour 270-K, 270-KSL | 320-K, 320-KSL

|

Beveling Machine for Contours

Assfalg GmbH

Deburring and edge milling machines; stationary

1011, 1053, 961, 938

The stationary edge- and contour milling machines are perfect for machining angular and round workpieces with plane inner- and outer contours. They are compact and handy tabletop machines finding their ideal use alongside CNC machines.

Professional advantages:

Professional advantages:

- Ideal for chamfers up to 1mm x 45°

- Suitable for processing small to medium-sized workpieces

- Low setup times with maximum flexibility

- Excellent chamfers by best spindle accuracy

- Zero point clamping

- Easy operation

- Fast tool change

- Speed control (only with Speedy Kontur 270-KSL and Speedy Kontur 320-KSL)

- Chamfer angle can be changed due to contour cutter with different point angles

Speedy Prisma 210-PSL

|

Beveling Machine with Sliding Carriage

Assfalg GmbH

Deburring and edge milling machines; stationary

57123, 46069

These deburring machines are simple and sturdy table machines equipped with a prismatic slide for efficient and precise machining of longitudinal edges down to smallest workpieces.

ADVANTAGES:

ADVANTAGES:

- Surface protecting precision chamfers up to 2 mm (no scratches on the workpiece)

- Easy operation

- Fast tool change

- Speed control for processing different materials

- Bearing supported sliding carriage for chatter-free milling

UA 5

|

Power Engine

Assfalg GmbH

Deburring and edge milling machines; stationary

29531

Whether grinding, polishing, brushing or deburring - the universal drive engine UA 5 is used in all materials. A wide variety of tools makes the machine very flexible and indispensable in your production.

Application:

Application:

- Mobile drive machine for the universal operation in the fabrication

- Grinding, polishing, brushing and deburring of all common materials with only one machine

- Flexible and mobile operation with flexible shaft

WKF 170

|

Chamfering Machine, angle adjustable

Assfalg GmbH

Deburring and edge milling machines; stationary

54307

The perfect machine for chamfering small to mid-size workpieces and bar material. Thanks to its angle adjustment from 15° - 60°, it is mainly used for welding seam preparation.

Professional advantages:

Professional advantages:

- Simple and fast angle adjustment

- Consistent high surface quality

- Automatic feed facilitates chamfering

- Sharp-edged chamfering is possible, e.g. a 5mm x 45°chamfer can be applied to a 5 mm thick workpiece

- Angleadjustment from 15° - 60° (in 5° steps)

- Chamfer adjustment by micrometer button

- Speed control for processing different materials

- Easy tool change

- Hardened and polished guide rails

- Soft cutting pressure