Blum-Novotest

Products

Measuring machines

Measuring machines, general

BMK 5 | BMK 3

|

Measuring machine, general

Blum-Novotest GmbH Fertigungs-Messtechnik

Measuring machines, general

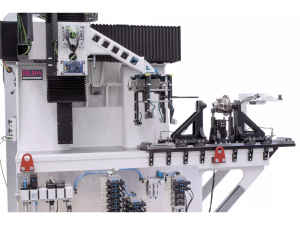

The measuring and automation concept BMK 5 is a variable measuring cell that can be expanded with modules. It can perform additional tasks such as sorting, labelling and packaging of components if the corresponding modules are integrated.

Your benefit

BMK3

Your benefit

- Applicable as stand-alone system or as in-line module in a machine tool

- Integrated as an in-line system with correction control loop or as an autonomous post-process test system

- Pair measurement and sorted storage/pre-assembly

- Inspection of workpieces from different machines/spindles using shared measuring station

- Flexibly equipped working area

- Manual or automated loading/unloading

- Adaption of up to 9 measuring and test modules with zero point clamping systems

- High efficiency by minimum setup costs

- Automated measurement without additional staff assignment

- Measuring – testing – automating | complete solutions from a single source

BMK3

- Part handling by 4-axis high-speed robot with vacuum gripper

- Inspection with imaging system

- Classification, tray stacking and sorted ejection

Crack Testing Machines

|

Measuring machine, general

Blum-Novotest GmbH Fertigungs-Messtechnik

Measuring machines, general

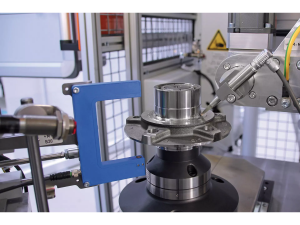

The range of applications for crack detection testing machines includes 100% testing of safety-critical components such as drive shafts, wheel hubs or brake discs. Non-destructive eddy-current crack testing is performed by a full scan of the relevant areas for testing within the production cycle.

Your benefit

Your benefit

- Eco-friendly, fast and fully-automated objective inspection

- Reliable identification and discharging of cracked parts

- High availability thanks to extremely solid and durable design

- Can be fully integrated into the production line

- Automation by means of inter-linkage, conveyor, shuttle, robot or gantry

- Can be individually extended to accommodate additional test criteria such as shrinkage cavities, pores, etc.

- Marking system for OK/NOK identification or individual coding

- Typically arrange immediately downstream of the machining station, often combined with a multipoint measuring machine

- Also available as measuring system for external control

- Linear axes

- Path control

- Flexible guidance by articulated robot

Flexible 2D Measuring Machines

|

Measuring machine, general

Blum-Novotest GmbH Fertigungs-Messtechnik

Measuring machines, general

Production-related quality assurance and maximum productivity are guaranteed by a correction interface to the machine tool. Customised for your process, the measuring system is suitable for medium and low-volume production.

Your benefit

Your benefit

- High availability thanks to extremely solid and durable design

- Automation by loading gantry (horizontal design) or robot (vertical design)

- Highly flexible due to software measuring sequence and NC clamping devices

- Practically rust-free

- Pulling and pushing measurements possible

- High availability and flexibility without time-consuming setting-up

- Outstanding precision even in harsh production environments

- No workpiece-specific calibration master required

- In-line measuring technology can also be fully integrated as an »in-line« or »post-process« system

- Manual or automated loading/unloading

- Correction interface

- Horizontal design

- Vertical design

Measuring machines for brake discs

|

Measuring machine, general

Blum-Novotest GmbH Fertigungs-Messtechnik

Measuring machines, general

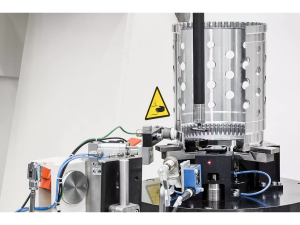

The multipoint measuring machines are designed for 100% quality monitoring. They provide static and/or dynamic testing, which records all measurement features in a single workpiece rotation under extreme production conditions such as casting dust or temperature fluctuations in the workpiece.

Your benefit

Your benefit

- High availability thanks to extremely solid and durable design

- Can be fully integrated into the production line

- Automation by means of inter-linkage, conveyor, shuttle, robot or gantry

- Ultra-precise thanks to optimum use of measuring sensors

- 100%-measurement with statistical quality control within the production cycle

- Precision and reliability, even in harsh production environments

- Testing technology with required scope of automation

- Also available as measuring system for external control

- Measuring – testing – automating | complete solutions from a single source

- Roller conveyor automation

- Swivel loader

- Direct loading on pre-storage

Multipoint Measuring Machines

|

Measuring machine, general

Blum-Novotest GmbH Fertigungs-Messtechnik

Measuring machines, general

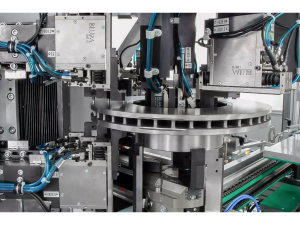

The multipoint measuring machines for rotationally symmetric workpieces offer quick acquisition of component geometry during dynamic measurement. Loading is possible manually as well as automatically. Its loading position is easy accessible from above right on top of the final measuring position.

Your benefit

Your benefit

- Post-process multipoint measuring system with independent PLC

- Easy integration into existing automation system

- Short, optimised feed motions

- Flexibly configurable measuring unit using measuring forks/callipers with intelligent universal clamping system

- Manual or automated loading/unloading

- High availability due to reduced changeover time

- Additional changeover monitoring (poka-yoke principle)

- Automatic calibration device

- Also available as measuring system for external control

- Dynamic testing for geometry and form

- Static geometry testing

SE100 | SL100

|

Measuring machine, general

Blum-Novotest GmbH Fertigungs-Messtechnik

Measuring machines, general

The test stand series for machine tool spindles combines the know-how of all three business divisions: The innovative test stands are available both as laboratory and end-of-line test stands and enable full testing and evaluation of the spindle quality.

Spindle test stands by Blum-Novotest

End-of-line and development test stands for motor spindles of machine tools

Spindle test stands by Blum-Novotest

End-of-line and development test stands for motor spindles of machine tools

- SE100 End-of-Line

- SL100 Laboratory Test Stand

Special Measuring Systems

|

Measuring machine, general

Blum-Novotest GmbH Fertigungs-Messtechnik

Measuring machines, general

Special measuring systems

Special measuring and testing systems by Blum-Novotest are specifically adapted to your requirements with regard to workpiece spectrum, measuring/test task and production environment.

Special measuring and testing systems by Blum-Novotest are specifically adapted to your requirements with regard to workpiece spectrum, measuring/test task and production environment.

- Truck differential housing

- Torque converter covers

Production measuring machines

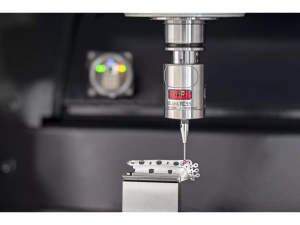

TC63-DIGILOG | TC64-DIGILOG

|

Production measuring machine

Blum-Novotest GmbH Fertigungs-Messtechnik

Production measuring machines

Advanced, scanning touch probes for milling and turning machines for automatic inspection of workpiece contours for machining errors. Exact measurement of workpiece position using digital measurement, extreme reduction in measuring time using cyberspeed, analogue scanning process.

TC63-DIGILOG | TC64-DIGILOG touch probes – Revolutionary touch probes for maximum in-process reliability during mass production

Future-oriented DIGILOG technology

TC63-DIGILOG | TC64-DIGILOG touch probes – Revolutionary touch probes for maximum in-process reliability during mass production

Future-oriented DIGILOG technology

- Detection of machining errors by analogue scan process in the machining centre

- Comparative measurement between master part and workpiece

- No production of NOK-parts due to downstream, external measurements

- Immediate rework in the original setting is possible

- Massive reduction of the measuring time when evaluating surfaces

- High-precision, face-geared measuring mechanism

- Wear-free, optoelectronic signal generation

- Defined deflection direction and constant deflection forces

- Extremely fast measurements

- Maximum measuring accuracy even with off-centre probing

- High measuring resolution for maximum precision and safety

- Reliable and proven transmission technology

- No influence on other radio systems

- Sequential use of up to 6 radio measuring systems with one receiver

- Very long battery life

TC63-RG Single

|

Production measuring machine

Blum-Novotest GmbH Fertigungs-Messtechnik

Production measuring machines

Surface roughness gauge specially for checking the surfaces of plane workpiece geometries in milling, turning and grinding machines. Automated and fast evaluation of surface roughness in the machining clamping by high-precision single measuring element.

TC63 RG Single – Detecting machining errors using automated roughness measurements during idle times

BLUM surface roughness gauges

TC63 RG Single – Detecting machining errors using automated roughness measurements during idle times

BLUM surface roughness gauges

- Automated roughness measurement without manual operator intervention

- Roughness measurement on surfaces of plane workpiece geometries

- Output of roughness parameters Ra, Rz, Rq, Rt, Rmax and Wt

- Enhanced in-process reliability by elimination of manual and downstream tests

- Determine problems of the cutting process

- Use of the expensive tools until the real end of the service life

- Protected by patents

- Wear-free, optoelectronic measuring mechanism

- High measuring resolution for maximum precision and safety

- Probing element similar to standard specifications

- Very low measuring force

- Reliable and proven transmission technology

- No influence on other radio systems

- Sequential use of up to 6 radio measuring systems with one receiver

- Very long battery life

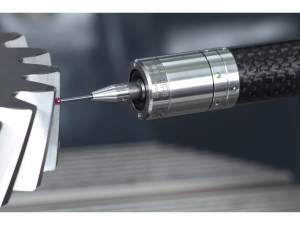

TC63-RG | TC64-RG | TC76-RG

|

Production measuring machine

Blum-Novotest GmbH Fertigungs-Messtechnik

Production measuring machines

Revolutionary roughness measuring systems for machining centres for precise evaluation of surface roughness of workpieces. Fast digital measurement of workpiece position and reliable detection of poor surface quality using analogue measurement.

TC63-RG | TC64-RG | TC76-RG – Globally unique roughness measuring systems for automatic checks in the original setting

BLUM roughness measuring systems

TC63-RG | TC64-RG | TC76-RG – Globally unique roughness measuring systems for automatic checks in the original setting

BLUM roughness measuring systems

- Automated roughness measurement without manual operator intervention

- Output of roughness parameters Ra, Rz, Rq, Rt, Rmax and Wt

- Enhanced in-process reliability by elimination of manual and downstream tests

- Determine problems of the cutting process

- Use of the expensive tools until the real end of the service life

- Protected by patents

- High-precision, face-geared measuring mechanism

- Wear-free, optoelectronic signal generation

- Defined deflection direction and constant deflection forces

- Extremely fast measurements

- Maximum measuring accuracy even with off-centre probing

- High measuring resolution for maximum precision and safety

- Reliable and proven transmission technology

- No influence on other radio systems

- Sequential use of up to 6 radio measuring systems with one receiver

- Very long battery life

TC76-DIGILOG

|

Production measuring machine

Blum-Novotest GmbH Fertigungs-Messtechnik

Production measuring machines

Hard-wired touch probes for turning and grinding machines for automatic inspection of workpiece contours for machining errors. Exact measurement of workpiece position using digital measurement, extreme reduction in measuring time using cyberspeed, analogue scanning process.

TC76-DIGILOG touch probe – One system, two technologies, thousands of measuring values

Future-oriented DIGILOG technology

TC76-DIGILOG touch probe – One system, two technologies, thousands of measuring values

Future-oriented DIGILOG technology

- Detection of machining errors caused by analogue scan process in the machining centre

- Comparative measurement between master part and workpiece

- No production of NOK-parts due to downstream, external measurements

- Immediate rework in the original setting is possible

- Massive reduction of the measuring time when evaluating surfaces

- High-precision, face-geared measuring mechanism

- Wear-free, optoelectronic signal generation

- Defined deflection direction and constant deflection forces

- Extremely fast measurements

- Maximum measuring accuracy even with off-centre probing

- High measuring resolution for maximum precision and safety

- Evaluation and visualisation at the control screen or BLUM Touch Panel TP48-21

- Early detection of “error trends”

- Comparative measurement between master part and workpiece

- Flexible definition of warning and tolerance limits per workpiece

- Providing the tracked data in log files

Three-dimensional measuring machines

TC50 | TC60

|

Three-dimensional measuring machine

Blum-Novotest GmbH Fertigungs-Messtechnik

Three-dimensional measuring machines

Universal touch probe systems for extremely fast measurements under the harshest conditions in medium and large machine tools. Superior precision and speed due to modern, multi-directional measuring mechanism with optoelectronic switch signal generation.

TC50 | TC60 touch probes – Manufacture more productively with measuring speeds of up to 3 m/min

Wear-free, optoelectronic signal generation

High-precision, rotationally symmetrical measuring mechanism

TC50 | TC60 touch probes – Manufacture more productively with measuring speeds of up to 3 m/min

Wear-free, optoelectronic signal generation

- The trigger signal is generated via shading of a miniature light barrier

- Enables much higher measuring speeds and accuracies than comparable touch probes

- Wear-free with long-term stability

High-precision, rotationally symmetrical measuring mechanism

- Precise, non-lobing touch characteristics

- Constant deflection forces

- Spindle indexing is not required

- No disadvantageous 3-leg principle with lobing effect

- No highly sensitive switching elements

- Probe TC50: Infrared transmission

- Probe TC60: BRC radio technology

- DUO-Mode: Sequential use of 2 infrared measuring systems with one receiver

- Sequential use of up to 6 radio measuring systems with one receiver

- TWIN mode: Simultaneous use of 2 radio measuring systems on one machine

- Very long battery life

TC51 | TC61

|

Three-dimensional measuring machine

Blum-Novotest GmbH Fertigungs-Messtechnik

Three-dimensional measuring machines

Touch probe specially designed for the requirements of CNC machining centres in highly productive manufacturing. Unique bidirectional measuring mechanism with optoelectronic switch signal generation for superior accuracy at maximum measuring speeds of up to 5 m/min.

TC51 | TC61 touch probes – Globally unique touch probes for fast pulling measurements

Wear-free and optoelectronic signal generation

TC51 | TC61 touch probes – Globally unique touch probes for fast pulling measurements

Wear-free and optoelectronic signal generation

- The trigger signal is generated via shading of a miniature light barrier

- Enables much higher measuring speeds and accuracy than with conventional probes

- Wear-free with long-term stability

- High-precision, bidirectional measuring mechanism

- Extremely fast measurements

- The probing direction in XY is defined by the orientation of the spindle

- For accelerations of up to 10g

- Spindle indexing is required

- TC51: Infrared Transmission

- TC61: BRC Radio Technology

- DUO-Mode: Sequential use of 2 infrared measuring systems with one receiver

- Sequential use of up to 6 radio measuring systems with one receiver

- TWIN mode: Simultaneous use of 2 radio measuring systems on one machine

- Very long battery life

TC52 | TC62

|

Three-dimensional measuring machine

Blum-Novotest GmbH Fertigungs-Messtechnik

Three-dimensional measuring machines

Universal touch probe for extremely fast measurements under the harshest conditions in medium and small machining centres. Workpiece measurement with superior precision and speed due to modern, multi-directional measuring mechanism with optoelectronic switch signal generation.

TC52 | TC62 – Maximum accuracy at measuring speeds of up to 2 m/min

Wear-free, optoelectronic signal generation

TC52 | TC62 – Maximum accuracy at measuring speeds of up to 2 m/min

Wear-free, optoelectronic signal generation

- The trigger signal is generated via shading of a miniature light barrier

- Enables much higher measuring speeds and accuracy than with conventional probes

- Wear-free with long-term stability

- Precise, non-lobing touch characteristics

- Constant deflection forces

- Spindle indexing is not required

- No disadvantageous 3-leg principle with lobing effect

- No highly sensitive switching elements

- TC52: Infrared Transmission

- TC62: BRC Radio Technology

- DUO-Mode: Sequential use of 2 infrared measuring systems with one receiver

- Sequential use of up to 6 radio measuring systems with one receiver

- TWIN mode: Simultaneous use of 2 radio measuring systems on one machine

- Very long battery life

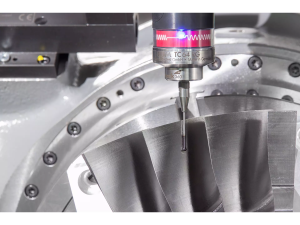

TC53 | TC63

|

Three-dimensional measuring machine

Blum-Novotest GmbH Fertigungs-Messtechnik

Three-dimensional measuring machines

Special 3D CNC touch probes for milling and turning machines for adaptation to customer-specific tasks. High precision due to innovative, face-geared shark360 measuring mechanism with optoelectronic switch signal generation.

TC53 | TC63 – 3D CNC touch probes, as flexible as your requirements

Wear-free, optoelectronic signal generation

TC53 | TC63 – 3D CNC touch probes, as flexible as your requirements

Wear-free, optoelectronic signal generation

- The trigger signal is generated via shading of a miniature light barrier

- Enables much higher measuring speeds and accuracy than with conventional probes

- Wear-free with long-term stability

- Face-geared measuring mechanism

- Maximum measuring accuracy even with off-centre probing

- Enables pulling and torsion-exposed measurements

- Constant deflection forces

- No preferred direction

- Enables the use of extensions and elbows

- TC53: Infrared Transmission

- TC63: BRC Radio Technology

- DUO-Mode: Sequential use of 2 infrared measuring systems with one receiver

- Sequential use of up to 6 radio measuring systems with one receiver

- TWIN mode: Simultaneous use of 2 radio measuring systems on one machine

- Very long battery life

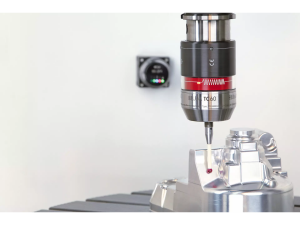

TC54-10 | TC64-10

|

Three-dimensional measuring machine

Blum-Novotest GmbH Fertigungs-Messtechnik

Three-dimensional measuring machines

Versatile touch probe for die tool and workpiece measurement under the harshest conditions. Precise and fast measurements thanks to innovative, face-geared shark360 measuring mechanism with optoelectronic switch signal generation.

TC54-10 | TC64-10 – The ideal probes for turning machines and pulling measurements

Wear-free, optoelectronic signal generation

Patented and face-geared shark360 measuring mechanism

TC54-10 | TC64-10 – The ideal probes for turning machines and pulling measurements

Wear-free, optoelectronic signal generation

- The trigger signal is generated via shading of a miniature light barrier

- Enables much higher measuring speeds and accuracy than with conventional probes

- Wear-free with long-term stability

Patented and face-geared shark360 measuring mechanism

- Face-geared measuring mechanism

- Maximum measuring accuracy even with off-centre probing

- Enables pulling and torsion-exposed measurements

- Constant deflection forces

- No preferred direction

- TC54-10: Infrared Transmission

- TC64-10: BRC Radio Technology

- DUO-Mode: Sequential use of 2 infrared measuring systems with one receiver

- Sequential use of up to 6 radio measuring systems with one receiver

- TWIN mode: Simultaneous use of 2 radio measuring systems on one machine

- Very long battery life

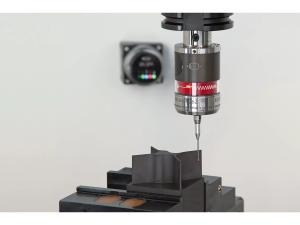

TC55

|

Three-dimensional measuring machine

Blum-Novotest GmbH Fertigungs-Messtechnik

Three-dimensional measuring machines

Our smallest wireless probe to date for workpiece and tool measurement in CNC machine tools. It is deployed in compact milling, turning and millturning centres used for microprocessing, medical technology and the measurement of components on machines for additive manufacturing.

TC55 – Ultra-compact all-rounder with infrared transmission

Wear-free, optoelectronic signal generation

This touch probe is available with infrared technology:

TC55 – Ultra-compact all-rounder with infrared transmission

Wear-free, optoelectronic signal generation

- The trigger signal is generated via shading of a miniature light barrier

- Enables much higher measuring speeds and accuracy than with conventional probes

- Wear-free with long-term stability

- Face-geared measuring mechanism

- Maximum measuring accuracy even with off-centre probing

- Enables pulling and torsion-exposed measurements

- Constant deflection forces

- No preferred direction

This touch probe is available with infrared technology:

- Extremely fast and reliable transmission

- Sequential use of 2 infrared measuring systems with one receiver (DUO mode)

- Smallest wireless probe from BLUM

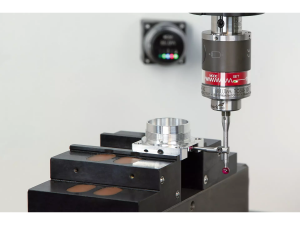

TC76

|

Three-dimensional measuring machine

Blum-Novotest GmbH Fertigungs-Messtechnik

Three-dimensional measuring machines

Versatile, hard-wired touch probe for tool and workpiece measurement in highly productive conditions. Precise and fast measurements thanks to innovative, face-geared shark360 measuring mechanism with optoelectronic switch signal generation.

TC76 touch probe – The ideal probe for turning machines and pulling measurements

Wear-free, optoelectronic signal generation

TC76 touch probe – The ideal probe for turning machines and pulling measurements

Wear-free, optoelectronic signal generation

- The trigger signal is generated via shading of a miniature light barrier

- Enables much higher measuring speeds and accuracy than with conventional probes

- Wear-free with long-term stability

- Face-geared measuring mechanism

- Maximum measuring accuracy even with off-centre probing

- Enables pulling and torsion-exposed measurements

- Constant deflection forces

- No preferred direction

- Extensions and elbows allow for user-specific adaptation

- Cranked styli

- Installation on machine table or wall using optional socket

- Tool measurement using stylus with cube