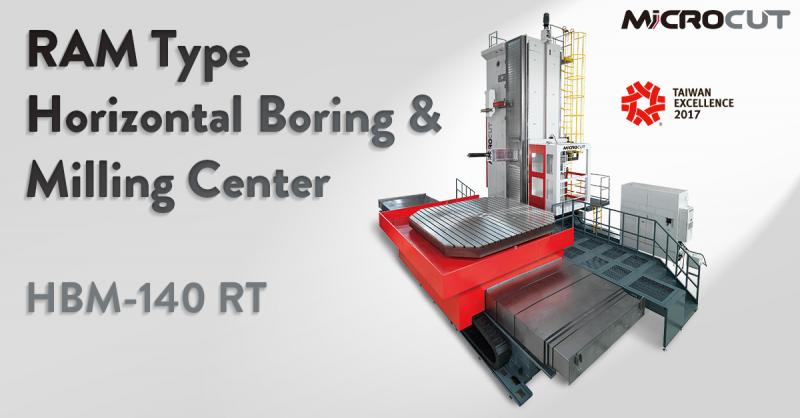

HBM-140RT is the RAM-type horizontal boring and milling center with high tensile strength column structure and the ram-type spindle. It is developed to meet the demands from oil, gas, shipbuilding, energy, and large mold industries. Also, HBM-140RT is equipped with the smart Straightness Compensation Technology (SCT) to optimize the stability, which offsets the deformation caused by gravity when Ram or quill extends to retain the accuracy.

HBM-140RT is specially designed for heavy-duty cutting, the standard table 3200mm x 3200mm offers a capacity of 20 tons, while an optional table 3500mm x 3500mm can handle up to 40 tons. The rotary table offers 0.001° high indexing accuracy. It is also driven by the dual planetary gear reducer to ensure the table backlash-free. The spindle is equipped with Ø140mm quill with 700mm travel and an extendable RAM that provides 800mm of travel. Linear guideway ram or hydrostatic ram is available for selection. And the ISO50 spindle with 3,000rpm spindle speed, it is supported by cylindrical roller bearings for heavy cutting.

HBM-140RT provides a comfortable operation with large working area and ergonomic control panel. The machine is equipped with linear scales on three axes, spindle oil cooling system, an arm-type magazine with 60-tool capacity and chip auger. An optional floor type chip conveyor is available for request.

Taiwan

Taiwan