Innovation: ADC Adaptive Drilling Control: New technology cycle for drilling

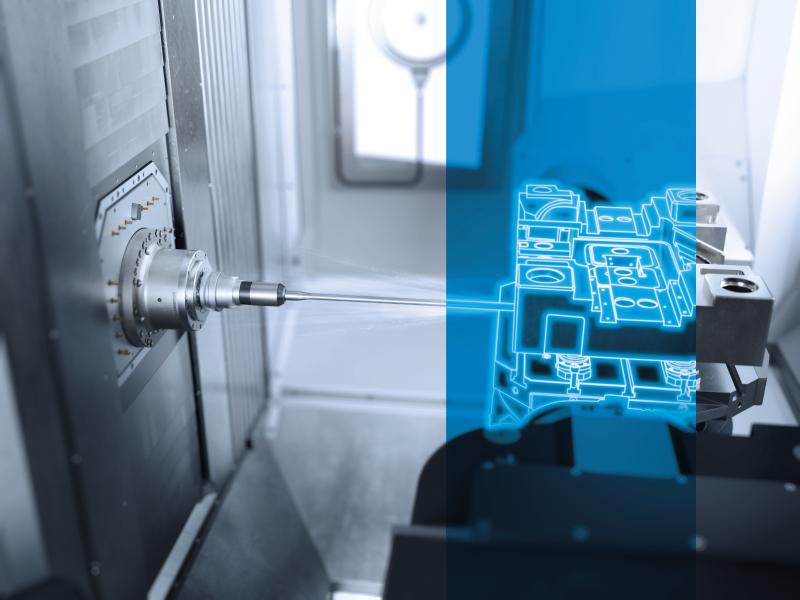

Munich. At its 2026 in-house exhibition in Pfronten, DMG MORI will present the Adaptive Drilling Control (ADC) technology cycle, a new milestone in process reliability, quality, and ease of use for drilling on universal machining centers. Deep hole drilling and gun drilling in particular place high demands on the operator and the machine. This technology makes the process controllable. ADC transforms a complex technology that was previously based on experience into an actively controlled and monitored drilling process—with measurable standards for process reliability, increased quality and service life, ease of operation, process monitoring, and energy efficiency.

From critical special case to regulated standard procedure

Deep hole drilling in particular is one of the most critical individual operations in machining. Chip jams, misaligned holes, cross holes, or tool breakage not only result in scrap, but also jeopardize delivery dates and customer relationships—especially for components with high added value such as crankshafts, injection systems, turbine components, or medical implants.

With the increasing shift of specialized deep hole drilling work to universal machining centers, responsibilities are shifting: highly specific requirements are encountering an environment in where not every operator has expert knowledge specific to deep drilling. Classic cycles work with rigid parameters here. As soon as the material, tool condition, or cooling lubricant deviates from the ideal, the process risk increases abruptly.

Adaptive Drilling Control from DMG MORI addresses precisely this weak point. The process is no longer just set, but actively and adaptively controlled. Sensors for pressure, flow, and load continuously provide status information, which the ADC cycle uses to control the coolant supply and machining strategy in a closed control loop.

One cycle for all drilling applications

ADC also combines standard drilling, deep hole drilling, and complex gunDRILL applications in a continuous technology cycle with three scalable modes:

- Standard drilling: The operator only needs the basic parameters (position/pattern, drilling data). Additional parameters for coolant pressure or volume flow are not required—the cycle ensures the optimum flow rate, which in practice increases the robustness and safety of the process.

- Deep hole drilling: A few additional input fields for classic deep hole drilling supplement the above information.

- ADC Advanced (gun drill/deep hole drilling): Additional options for complex requirements such as cross holes, offset to the pilot hole, and adaptive feed adjustment can be easily added here using the dialog box.

ADC automatically adjusts the coolant pressure and flow rate to the material, tool, and process phase without manual intervention. The result is stable flow rates that vary depending on chip accumulation, cross-drilling, and drilling depth through continuous pressure adjustment. This technology increases process reliability and quality and extends service life by 30 percent. Energy savings of up to 30 percent are an additional positive side effect, which favors equipping the machine with special cooling lubricants for pressures of over 80 bar. In this way, a complex process can be designed as a standard process.

Technology meets partner expertise

The ADC technology cycle was developed in close cooperation with leading partners in the DMG MORI Qualified Products Network (DMQP) in order to achieve the best results in combination with DMG MORI machines. The tool specialists botek Präzisionsbohrtechnik, Gühring, Kennametal, and Walter worked together with DMG MORI to develop coordinated adaptive process control. FUCHS Lubricants supplies cooling lubricant formulations that guarantee stable properties across a wide range of pressures and flow rates. It is this partnership that makes ADC a complete solution.

Cost-effectiveness and auditability

ADC addresses the cost drivers of deep hole drilling in two dimensions: Controlled chip removal, reduced load peaks, and defined response logic massively reduce the likelihood of tool breakage and scrap. At the same time, adaptive coolant supply reduces energy consumption and extends tool life through more stable temperature control. Another important aspect is the improvement in quality, such as the course of the borehole or surface, which can also lead to scrap. All process data is automatically recorded and is available for monitoring, quality documentation, and integration into CELOS X and factory IT systems. Industries with high accountability requirements—aerospace, medical technology, automotive—benefit from standardized cycles and a complete process history for each hole.

Availability and Machining Transformation (MX)

ADC is initially available on the monoBLOCK, duoBLOCK, DMC H monoBLOCK, DMC 55 H TWIN, and portal and gantry machine series. Siemens and HEIDENHAIN controls are supported. DMG MORI sees ADC as a strategic component of Machining Transformation (MX). Sensors, control systems, software, and the partner ecosystem are intelligently bundled to process demanding components more efficiently.

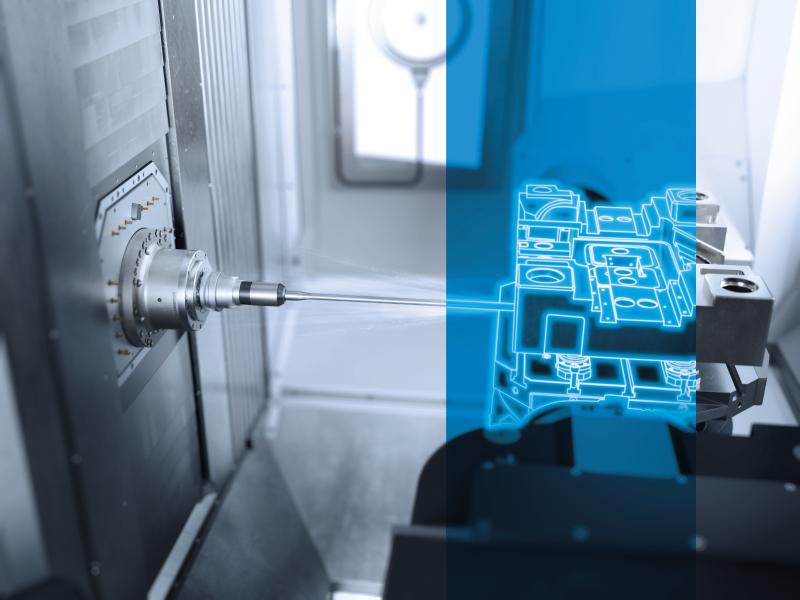

Munich. At its 2026 in-house exhibition in Pfronten, DMG MORI will present the Adaptive Drilling Control (ADC) technology cycle, a new milestone in process reliability, quality, and ease of use for drilling on universal machining centers. Deep hole drilling and gun drilling in particular place high demands on the operator and the machine. This technology makes the process controllable. ADC transforms a complex technology that was previously based on experience into an actively controlled and monitored drilling process—with measurable standards for process reliability, increased quality and service life, ease of operation, process monitoring, and energy efficiency.

From critical special case to regulated standard procedure

Deep hole drilling in particular is one of the most critical individual operations in machining. Chip jams, misaligned holes, cross holes, or tool breakage not only result in scrap, but also jeopardize delivery dates and customer relationships—especially for components with high added value such as crankshafts, injection systems, turbine components, or medical implants.

With the increasing shift of specialized deep hole drilling work to universal machining centers, responsibilities are shifting: highly specific requirements are encountering an environment in where not every operator has expert knowledge specific to deep drilling. Classic cycles work with rigid parameters here. As soon as the material, tool condition, or cooling lubricant deviates from the ideal, the process risk increases abruptly.

Adaptive Drilling Control from DMG MORI addresses precisely this weak point. The process is no longer just set, but actively and adaptively controlled. Sensors for pressure, flow, and load continuously provide status information, which the ADC cycle uses to control the coolant supply and machining strategy in a closed control loop.

One cycle for all drilling applications

ADC also combines standard drilling, deep hole drilling, and complex gunDRILL applications in a continuous technology cycle with three scalable modes:

- Standard drilling: The operator only needs the basic parameters (position/pattern, drilling data). Additional parameters for coolant pressure or volume flow are not required—the cycle ensures the optimum flow rate, which in practice increases the robustness and safety of the process.

- Deep hole drilling: A few additional input fields for classic deep hole drilling supplement the above information.

- ADC Advanced (gun drill/deep hole drilling): Additional options for complex requirements such as cross holes, offset to the pilot hole, and adaptive feed adjustment can be easily added here using the dialog box.

ADC automatically adjusts the coolant pressure and flow rate to the material, tool, and process phase without manual intervention. The result is stable flow rates that vary depending on chip accumulation, cross-drilling, and drilling depth through continuous pressure adjustment. This technology increases process reliability and quality and extends service life by 30 percent. Energy savings of up to 30 percent are an additional positive side effect, which favors equipping the machine with special cooling lubricants for pressures of over 80 bar. In this way, a complex process can be designed as a standard process.

Technology meets partner expertise

The ADC technology cycle was developed in close cooperation with leading partners in the DMG MORI Qualified Products Network (DMQP) in order to achieve the best results in combination with DMG MORI machines. The tool specialists botek Präzisionsbohrtechnik, Gühring, Kennametal, and Walter worked together with DMG MORI to develop coordinated adaptive process control. FUCHS Lubricants supplies cooling lubricant formulations that guarantee stable properties across a wide range of pressures and flow rates. It is this partnership that makes ADC a complete solution.

Cost-effectiveness and auditability

ADC addresses the cost drivers of deep hole drilling in two dimensions: Controlled chip removal, reduced load peaks, and defined response logic massively reduce the likelihood of tool breakage and scrap. At the same time, adaptive coolant supply reduces energy consumption and extends tool life through more stable temperature control. Another important aspect is the improvement in quality, such as the course of the borehole or surface, which can also lead to scrap. All process data is automatically recorded and is available for monitoring, quality documentation, and integration into CELOS X and factory IT systems. Industries with high accountability requirements—aerospace, medical technology, automotive—benefit from standardized cycles and a complete process history for each hole.

Availability and Machining Transformation (MX)

ADC is initially available on the monoBLOCK, duoBLOCK, DMC H monoBLOCK, DMC 55 H TWIN, and portal and gantry machine series. Siemens and HEIDENHAIN controls are supported. DMG MORI sees ADC as a strategic component of Machining Transformation (MX). Sensors, control systems, software, and the partner ecosystem are intelligently bundled to process demanding components more efficiently.