durcrete at EMO 2025 in Hannover

ULTRA-HIGH-STRENGTH CASTING COMPOUND - WORLD'S HIGHEST MODULUS OF ELASTICITY

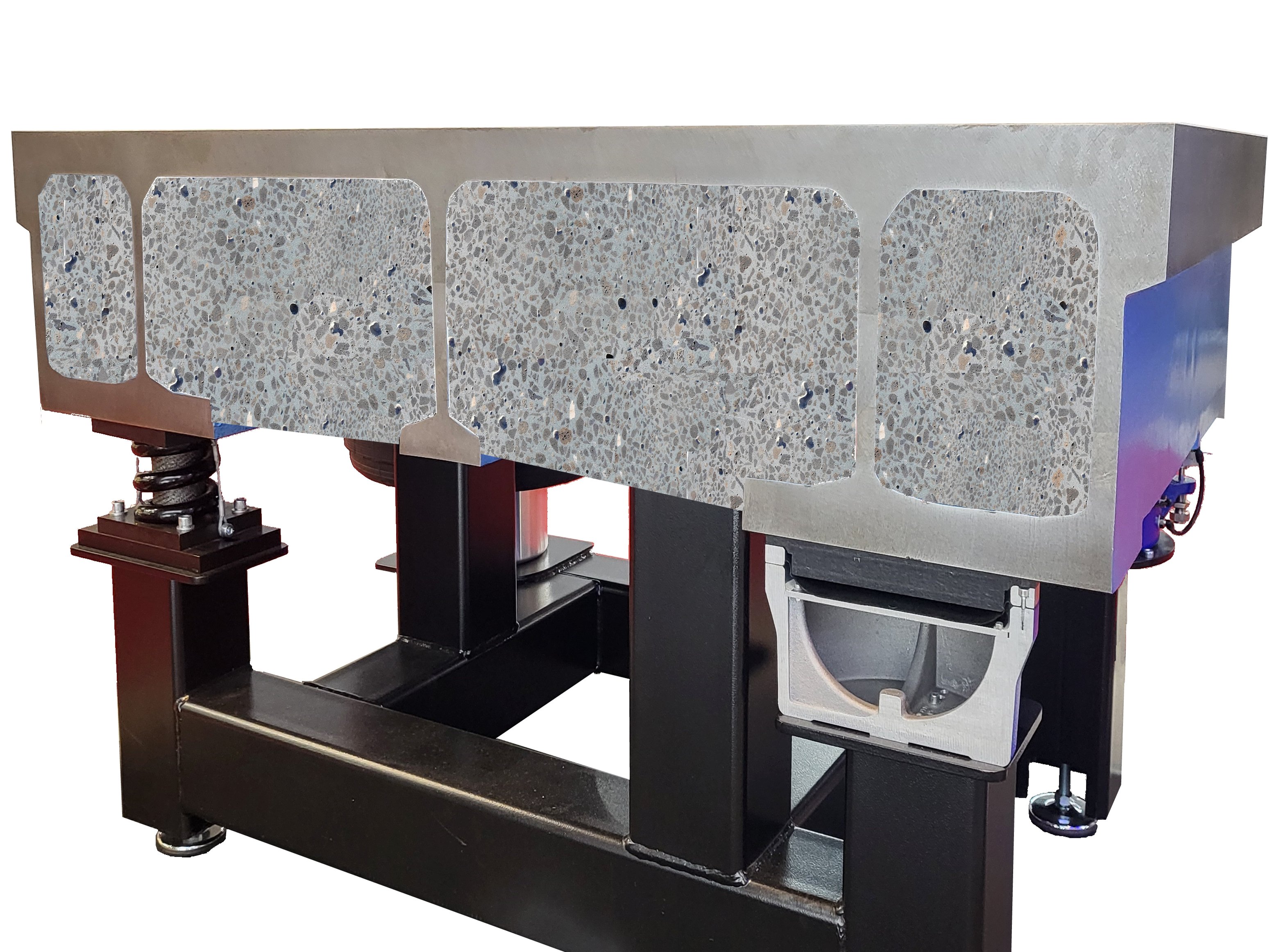

durcrete GmbH, the specialist company for cement-bound mineral casting in mechanical engineering, has developed the ultra-high-strength casting compound “durfill E” together with Dyckerhoff GmbH. The “E” stands for “increased modulus of elasticity”; with a modulus of elasticity of over 65,000 N/mm², it has the world's highest modulus of elasticity for mechanical engineering. Machine deformations can thus be significantly reduced and the natural frequencies drastically increased. A decisive advantage for modern applications such as test benches in e-mobility.

For over 15 years, durcrete GmbH has been supplying machine tool manufacturers with solid, vibration-damping machine beds made of cement-bonded cast mineral UHPC. New for EMO 2025 is “durfill E”, a mineral casting compound that sets new standards for cement-bound dry-mix mortars for mechanical engineering with a modulus of elasticity of 65,000 MPa, the highest value in the world. A value that is significantly higher than that of all other common filling materials used in mechanical engineering. This also minimizes deformation and maximizes the natural frequency. As durcrete uses the special binder NANODUR from Dyckerhoff GmbH as a binding agent, this high deformation resistance of the purely mineral product is also present at temperatures of up to 90°C.

Focus on ease of use

The aim of this innovation, in which natural stone is replaced by an industrially hardened aggregate, was to make it particularly easy to use. As with the previous standard product “durfill S”, the unproblematic mixing, the finished premix from the bag, the easy pourability of the self-compacting mass in free-form constructions and, last but not least, the simple cleaning with water and the unproblematic disposal of residues are retained. “Durfill E” is designed as a ready-mixed dry mortar exclusively for mechanical engineering and has been thoroughly tested by certified test laboratories.

The perfect material for many applications

The switch to e-mobility means that electric drives and the associated gearboxes have significantly higher speeds of up to 30,000 rpm than combustion engines. The test tables, frames and test rigs, which are usually custom-made, therefore require a high natural frequency in order not to falsify the measurement results. However, the cast iron clamping, measuring or grooving plates used in machine tools are also subjected to ever-increasing loads, causing resonance and making it impossible to achieve uniform machining without chatter marks or undisturbed measurement. With “durfill E”, it is possible to upgrade existing gray cast iron constructions directly in the factory and is economically very interesting in terms of both cost and speed. The high modulus of elasticity is automatically accompanied by high impermeability and strength. Therefore, “durfill E” can also be used for highly stressed, filigree, thin sheet metal constructions in which the steel shell is functionally minimized as a pure casting mould and for local anchoring of the screw connections and precision surfaces. All loads are transferred by the mineral casting material. “Durfill E” is the perfect material for constructions that require a high natural frequency, high rigidity and mechanical and thermal inertia combined with excellent damping.

Contact address

Dr.-Ing. Bernhard Sagmeister

█ durcrete 15 Jahre Ingenieurleistung für Ihren Erfolg

Maschinenbauteile aus Ultra High Performance Concrete UHPC

■ Telefon +49 6431 58 40 376 ■ E-Mail [email protected] ■ durcrete GmbH

■ Am Huttig 4 ■ D-65549 Limburg/Lahn ■ Germany ■ [email protected]

■ Sitz Limburg a. d. Lahn ■ Amtsgericht Limburg HRB 4483 ■ USt-IdNr.: DE268482655

■ Geschäftsführer B. Sagmeister ■ TECHNOLOGIEPARTNER DYCKERHOFF

NANODUR® ■ Privatdozent an der RPTU Kaiserslautern-Landau

■ www.durcrete.de Info zu Maschinenbau ■ www.durcrete.com Info zum Bauwesen

www.durcrete.de

Bernhard Sagmeister, Managing Director durcrete GmbH

ULTRA-HIGH-STRENGTH CASTING COMPOUND - WORLD'S HIGHEST MODULUS OF ELASTICITY

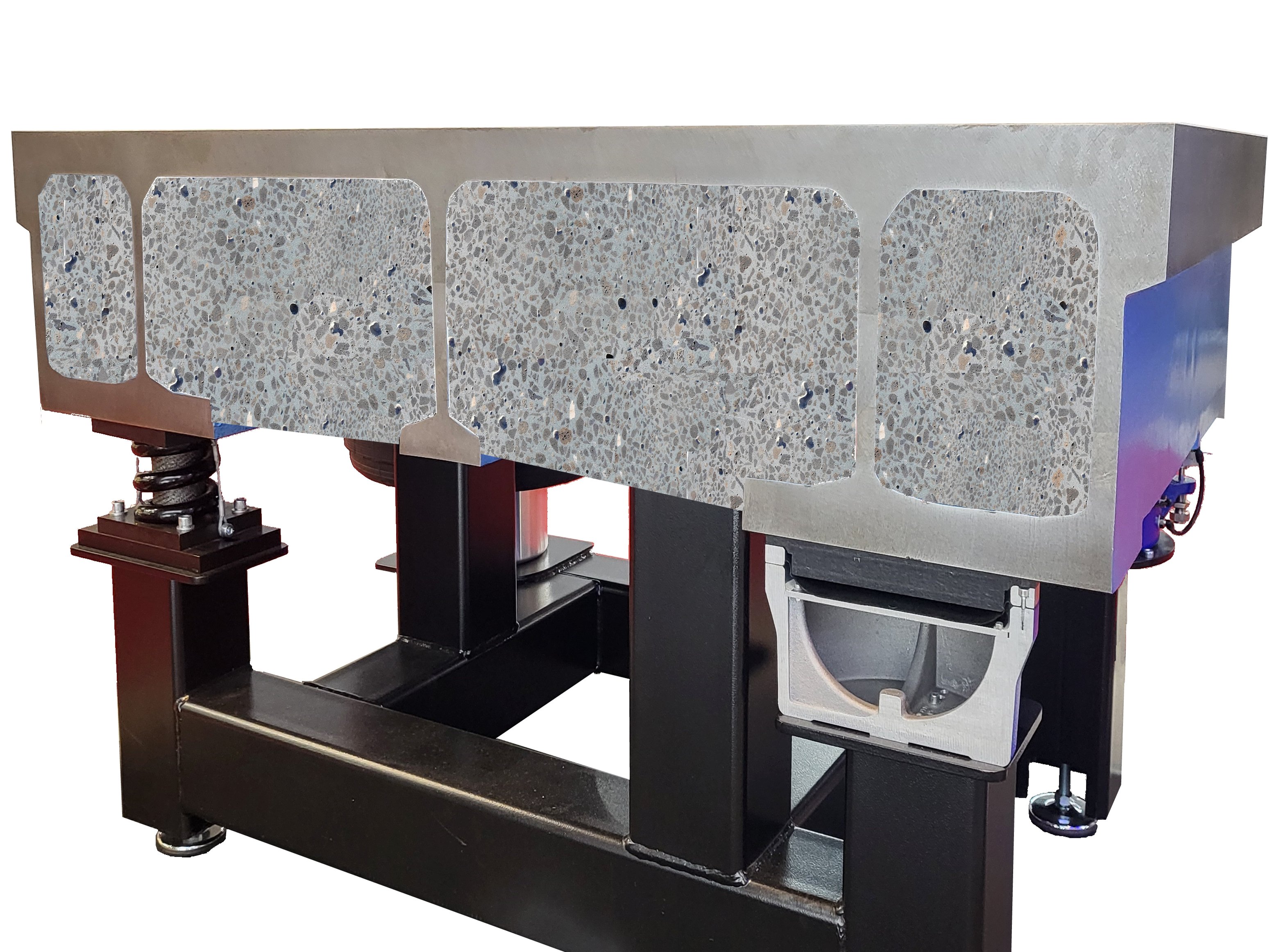

durcrete GmbH, the specialist company for cement-bound mineral casting in mechanical engineering, has developed the ultra-high-strength casting compound “durfill E” together with Dyckerhoff GmbH. The “E” stands for “increased modulus of elasticity”; with a modulus of elasticity of over 65,000 N/mm², it has the world's highest modulus of elasticity for mechanical engineering. Machine deformations can thus be significantly reduced and the natural frequencies drastically increased. A decisive advantage for modern applications such as test benches in e-mobility.

For over 15 years, durcrete GmbH has been supplying machine tool manufacturers with solid, vibration-damping machine beds made of cement-bonded cast mineral UHPC. New for EMO 2025 is “durfill E”, a mineral casting compound that sets new standards for cement-bound dry-mix mortars for mechanical engineering with a modulus of elasticity of 65,000 MPa, the highest value in the world. A value that is significantly higher than that of all other common filling materials used in mechanical engineering. This also minimizes deformation and maximizes the natural frequency. As durcrete uses the special binder NANODUR from Dyckerhoff GmbH as a binding agent, this high deformation resistance of the purely mineral product is also present at temperatures of up to 90°C.

Focus on ease of use

The aim of this innovation, in which natural stone is replaced by an industrially hardened aggregate, was to make it particularly easy to use. As with the previous standard product “durfill S”, the unproblematic mixing, the finished premix from the bag, the easy pourability of the self-compacting mass in free-form constructions and, last but not least, the simple cleaning with water and the unproblematic disposal of residues are retained. “Durfill E” is designed as a ready-mixed dry mortar exclusively for mechanical engineering and has been thoroughly tested by certified test laboratories.

The perfect material for many applications

The switch to e-mobility means that electric drives and the associated gearboxes have significantly higher speeds of up to 30,000 rpm than combustion engines. The test tables, frames and test rigs, which are usually custom-made, therefore require a high natural frequency in order not to falsify the measurement results. However, the cast iron clamping, measuring or grooving plates used in machine tools are also subjected to ever-increasing loads, causing resonance and making it impossible to achieve uniform machining without chatter marks or undisturbed measurement. With “durfill E”, it is possible to upgrade existing gray cast iron constructions directly in the factory and is economically very interesting in terms of both cost and speed. The high modulus of elasticity is automatically accompanied by high impermeability and strength. Therefore, “durfill E” can also be used for highly stressed, filigree, thin sheet metal constructions in which the steel shell is functionally minimized as a pure casting mould and for local anchoring of the screw connections and precision surfaces. All loads are transferred by the mineral casting material. “Durfill E” is the perfect material for constructions that require a high natural frequency, high rigidity and mechanical and thermal inertia combined with excellent damping.

Contact address

Dr.-Ing. Bernhard Sagmeister

█ durcrete 15 Jahre Ingenieurleistung für Ihren Erfolg

Maschinenbauteile aus Ultra High Performance Concrete UHPC

■ Telefon +49 6431 58 40 376 ■ E-Mail [email protected] ■ durcrete GmbH

■ Am Huttig 4 ■ D-65549 Limburg/Lahn ■ Germany ■ [email protected]

■ Sitz Limburg a. d. Lahn ■ Amtsgericht Limburg HRB 4483 ■ USt-IdNr.: DE268482655

■ Geschäftsführer B. Sagmeister ■ TECHNOLOGIEPARTNER DYCKERHOFF

NANODUR® ■ Privatdozent an der RPTU Kaiserslautern-Landau

■ www.durcrete.de Info zu Maschinenbau ■ www.durcrete.com Info zum Bauwesen

www.durcrete.de

Bernhard Sagmeister, Managing Director durcrete GmbH