Level 4 - save time by automating tool reworking

In the previous post we discussed Gantry / Central Tool Storage tool automation. This is a system capable of sharing tools from a large, centralized tool storage to different machines, greatly improving machine tool utilization and lights-out times. With CTS, the only thing left up to the operators is tool reworking. But what happens when tool reworking starts to form a bottleneck on the shop floor? Extremely short tool lifetimes combined with a constant and high demand for renewed tools can quickly make tool reworking into a full-time job.

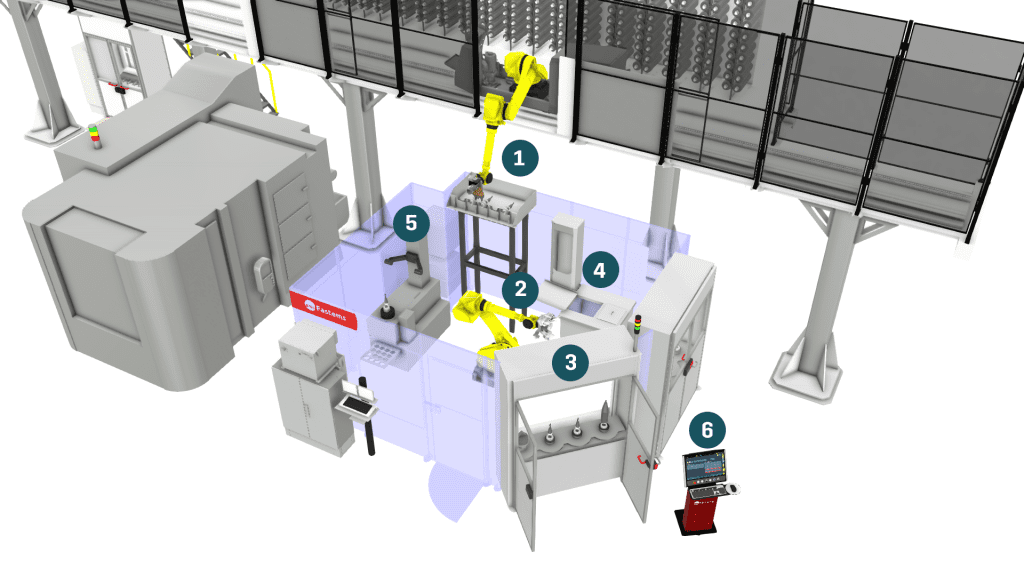

In these cases, tool automation can be extended to optimize the tool setup process as well, allowing for more efficient labor utilization for tool reworking. Let me introduce Tool Service Cell (TSC): Fastems’ latest development for the most advanced tool management needs.

How does TSC work?

You can read about this in the blog post on our webpage.