I am planning to build a XY Table for my new desktop CNC.

Using HIWIN HGW20CC Linear Rail.

Thinking about using 510mmX150mmX18mm 7075 alum for the bed.

Looking for accuracy at 0.02mm/300mm for the travel.

But is the bed will be rigid enough for this requirement?

The material I will be cutting is plastic, wood and 6061 alum.

The spindle is a 800w water cool.

HAINBUCH GMBH

Forum

SPANNENDE TECHNIK

Thread: XY Table Bed Design

Results 1 to 15 of 15

-

01-18-2012, 04:53 AM #1

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 210

XY Table Bed Design

-

01-18-2012, 05:55 AM #2

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 210

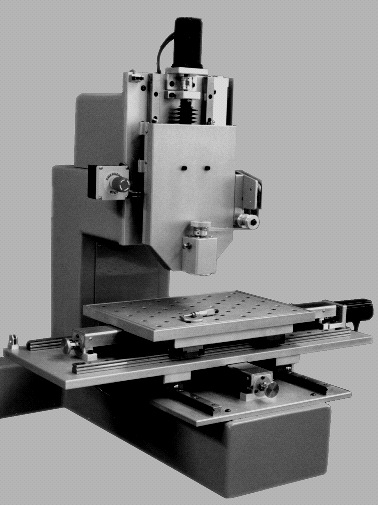

Got the 3 Axis layout done

This is my plan.

Travel is: 320mmx210mmx140mm

Material: 7075 Alum.

Total Weight so far (everything in the picture): 25Kg

Any comment will be welcome.

Thanks

Paul

-

01-18-2012, 12:25 PM #3

Registered

Registered

- Join Date

- Oct 2005

- Posts

- 2392

I can't say for sure but maybe it would be better to put the Y on the bottom and the longer X on top? Most mills I have seen are set up that way.

-

01-18-2012, 02:11 PM #4

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 210

That is true. I will switch X and Y. Now I am trying to figure out why is that. Is it bacause of balancing?

But from the load point of view, are we putting heavier (longer) one on the top now?

Thanks

-

01-18-2012, 07:34 PM #5

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 210

is it a better way just to build the 3 Axis seperately then use 8020 to do the whole structure. This way has more flexibilities to adjuest the relation ship between X, Y and Z.

What size of 8020 will be the best choice to build a rigid frame to mount the 3 axis for machining alum in the future?

Only for hobby parts machining, so not expecting high cutting speed.

-

01-18-2012, 08:27 PM #6

Registered

Registered

- Join Date

- Mar 2011

- Posts

- 584

3060 is the biggest 8020 makes in fractional. 40-8016 in metric. Get the tech tool box from their website they have a free deflection calculator.

80/20® Inc. - The Industrial Erector Set®

-

01-18-2012, 08:33 PM #7

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 210

Thanks. 3060 is pretty BIG. 20 size would look "comfortable" to me

But I will check out the calculator to see if I can figure it out.

Any rough rough idea how much it will cost to build the frame by using 8020 material?

Just want to compare with machining the frame.

Thanks

Paul

-

01-18-2012, 09:50 PM #8

Registered

Registered

- Join Date

- Mar 2011

- Posts

- 584

This may help items in 80 20 8020 Aluminum T-Slot T Slot extrusion 8020 garage sale store on eBay!

Check your local distributor I got my extrusion for cheaper then on the ebay store from a local distributor.

-

01-18-2012, 09:54 PM #9

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 210

Thanks for the link.

How about the cutting service 8020 provides?

Do they provide accurate cutting (Better than 0.05mm)?

-

01-18-2012, 10:23 PM #10

Registered

Registered

- Join Date

- Mar 2011

- Posts

- 584

Not sure. I know my stuff was right on the money for a tape measure. If you want to get that exact I would contact them or have it faced with milled

-

01-18-2012, 10:30 PM #11

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 210

May need a better design to avoid face milling. They have some brackets to do 90 degree connections. Couldn't find any parallelism and perpendicularity test data in this forum for those DIY CNC machines.Not sure why people don't do it. This would be the first thing I would check. This is very important for 2 side cutting.You don't see it for one side cutting. when you flip, all the errors show up

-

01-19-2012, 10:09 AM #12

Registered

Registered

- Join Date

- Oct 2005

- Posts

- 2392

-

01-19-2012, 02:19 PM #13

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 210

Otherwise it needs a very wide base?

-

01-19-2012, 02:24 PM #14

Registered

Registered

- Join Date

- Feb 2011

- Posts

- 210

Hi RomanLini, where did you find the second picture? This could be my design model.

In the first picture, is the table going to "twist" Y bearing when it moves to one side? I know HIWIN bearing will take it, but will it cause more error in the system? (like 0.001"?)

-

01-20-2012, 10:24 AM #15

Registered

Registered

- Join Date

- Oct 2005

- Posts

- 2392

Sorry I'm not sure where the photo originally came from, but I think it's a welded steel frame (the bottom photo).

As for the table twisting when the weight is on one side, it's possible I guess. Normally these machines are made for milling steel etc so the cutting forces from the tool are much more than any gravity forces, and also the bearing rails are designed to be very low-slop.

Similar Threads

-

Blackfoot 4x8 Table Top Design?

By j.steensen in forum DIY CNC Router Table MachinesReplies: 1Last Post: 09-26-2011, 06:18 PM -

Water table design

By daconfusion in forum Waterjet General TopicsReplies: 1Last Post: 02-22-2011, 07:30 PM -

Design Table

By hhakan in forum SolidworksReplies: 2Last Post: 11-07-2008, 04:27 PM -

XY table design basics, linear ways to table size ratio?

By Konstantin in forum Mechanical Calculations/Engineering DesignReplies: 0Last Post: 03-13-2007, 06:21 PM -

Looking for input on CNC table design

By yellow73bb in forum Waterjet General TopicsReplies: 2Last Post: 10-16-2006, 05:20 PM

Reply With Quote

Reply With Quote