MAS GmbH is sailing in uncharted territory - however, they are not getting lost –

Hainbuch and MAS are making the most of it

The two companies, the tool specialist, MAS, headquartered in Leonberg, and the Swabian clamping device manufacturer from Marbach, are a strong team.

When MAS decided to manufacture prototypes of special tools for customers, Hainbuch was manufacturer chosen for the clamping devices that would be used on the

Mori Seiki NTX2000 machine. The responsible persons knew that Hainbuch is unsurpassed wherever rigidity, stability, repeatability and holding forces are required.

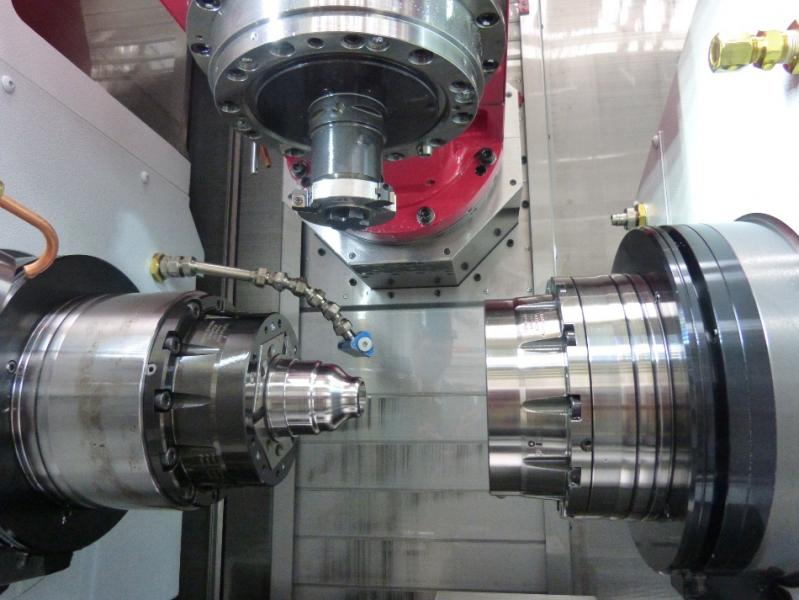

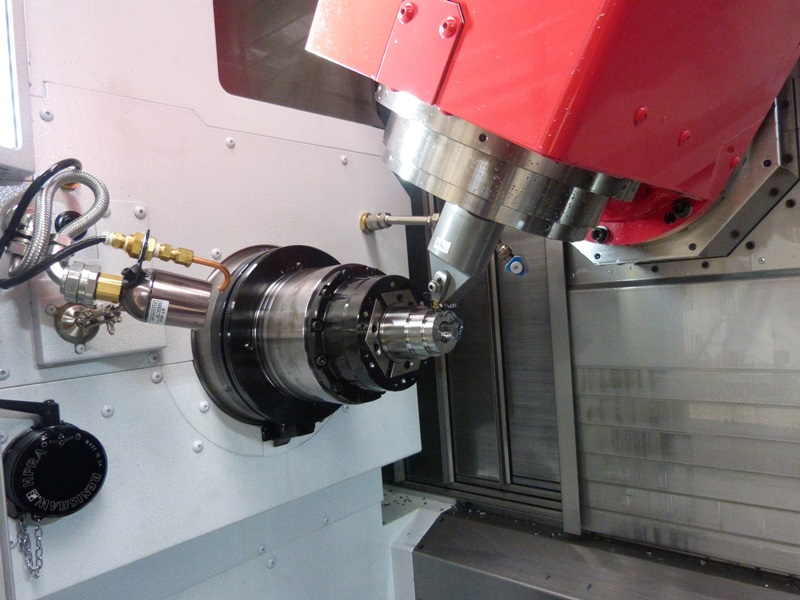

And consequently, sparks, or rather chips, have been flying at MAS since fall 2013. The company is more than satisfied with the hexagon Toplus mini hexagon chucks on

the main and sub spindles, in one instance as pull-back and in one as deadlength variant.

The mini chucks are small in size but big in performance

MAS has been a successful partner for Sumitomo in Baden-Württemberg for over 30 years, specifically with carbon and carbide cutting materials. Marc Decker, who is responsible for process development at MAS, states: »Enquiries for special tools, in-house developments, tool tests, and customer tests were piling up. We needed a solution, to manufacture prototypes for semi-standard tools, which after release would immediately go into the production.« For example, boring bars with a diameter from 0.65 - 3 mm and grooving tool holders with internal cooling could no longer be covered by a standard tools. Consequently, to remedy the situation the company invested in a milling-turning center from Mori Seiki. »However, one thing was very clear for us: If we were going to buy a machine on which only trials and tool tests would be executed, then we wanted eliminate all other errors«, explains Decker. »The question of the right clamping device was easy to answer; only a high-end product from Hainbuch is suitable for such a machine.« Through Decker's earlier activity for a large machine builder Hainbuch was known and the experiences with the clamping devices were very positive. Decker and his colleagues are fully convinced of the long longevity and user friendly set-up.

Therefore there was no thought whatsoever of a different clamping device manufacturer. »We had Achim Platzer, Outside Sales Manager at Hainbuch come to our facility to discuss all the details. Then Mr. Platzer recommended the Toplus mini chuck, due to the minimal interference contour and the better tool accessibility. In retrospect, this turned out to be the absolute correct decision«, reports Decker. »Since we now have a small and handy system. Due to the thin wall we do not have a single disadvantage compared to a regular standard chuck. Our experiences with the minis are continued to be positive. Rough machining to 6 mm functions are not a problem.

We have minimal inertia loss, and stability deficits do not occur at all.«

Waiting times reduced to a minimum

»Time is money«, as they say, and this is what MAS recognized. In addition to the new milling-turning center from Mori Seiki, a high-precision turning machine from Krummer was also purchased. Moreover, the company invested in a new CAD/CAM System NX from Siemens, hired a designer, and a measuring workstation was provided.

Decker recounts: »Thanks to this newly-created test department, we were able to drastically reduce the throughput time in developing new tools by 75%, believe it or not. It is simply a fact that when something is outsourced, it takes a long time. But those days are gone; with the Mori Seiki machine and the Hainbuch chucks we can present a wide variety of machining processes, such as turning, milling, drilling or multi-side machining operations. We manufacture the tool. We test it immediately and if necessary we make additional adjustments, and then we deliver it to the customer. If customers have problem components for which they are not getting the longevity and requirements right, we support them in this area as well. We simulate the customer's process on the machine. Check to determine where there are issues and where improvements can be made.

Future plans for 2015

MAS is investing in a new building, including a testing and demonstration center, which will open its doors in the summer of 2015. At that time the Mori Seiki machine will be moved from its current location at the DMG showroom, to the company's own facilities. Then when new products are introduced to the market, the company's own outside sales and service employees can be better trained. A variety of workshops will be offered to customers, covering a wide variety of machining jobs. This means that customers will not only profit from faster prototyping for special tools, they will also profit from well-trained employees and the special training courses. And who knows, perhaps there will be additional machine investments in the future and then MAS can again count on the consulting, the service on the right products from Hainbuch.

Germany

Germany