SPANNENDE TECHNIK

The new "jaw module generation"

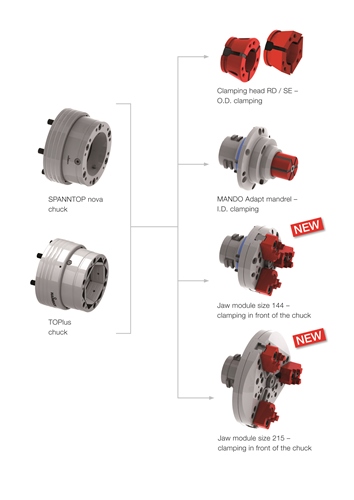

MARBACH. This energy-efficient compact device solves big problems; it redefines jaw clamping and marks the beginning of a new era in workholding. Hainbuch presents a jaw module that is small, flexible, that can be quickly changed, and covers a large clamping range. And best of all: Together the two partners, Spanntop chuck and jaw module, do not just result in a jaw chuck, they become a quick change clamping solution for all situations. Mandrels and clamping heads can also be used in the basic unit. The new jaw module completes the circle and gives a new clamping dimension that opens up even more possibilities for users. All this with less weight and a smaller interference contour and the usual Hainbuch accuracy. In short: The perfect 3‑in‑1‑combination - I.D. clamping, O.D. clamping, and jaw clamping.

Everything is possible, one fits into the other -

the extension in the Hainbuch modular system.

Small, but still powerful with no compromises

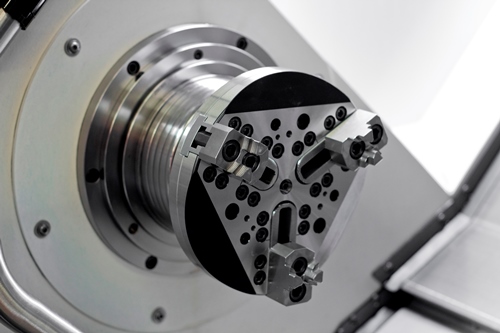

»A great little idea«, at the time this is how VW advertised the introduction of the Lupo, and the statement is also quite appropriate for the new jaw module. The Hainbuch solution, consisting of a chuck and a jaw module, has nothing in common with the large, heavy, energy sapping big jaws that can be found in many machine shops; where their size is more of an obstacle than an advantage. These heavy chucks put load on the machine spindle and are slow to accelerate and decelerate losing time and using energy. This takes longer for the part to be produced and hence makes it more expensive and also wears the machine bearings out quicker. This is squandering of energy and piece rate time in its purest form. Naturally these are costs that today no one can afford or want to pay. Lets assume that someone purchases a lathe/milling machine with spindle taper DIN A2-6 65mm bar capacity, here the workpiece range is usually diameter of 10 to 200 mm. To cover that range a machine with a 215 jaw chuck is purchased. However 80% of the components are in a clamping range of 100 mm and smaller. And here the dilemma arises that in practice you have to cope daily with: Large clamping device - small workpiece. It is difficult to get all of the tools in place, often the tools will not reach center line and often special tools are required with longer reach increasing vibration and losing accuracy, also there is a high risk of collision.

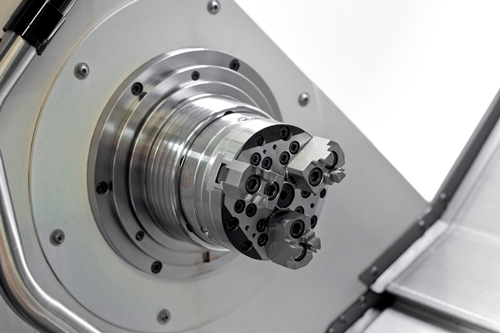

Jaw chuck Spanntop with new jaw module, size 144.

Multitasking hero? We think so!

Hainbuch modular solutions make sense and they are just as capable of multitasking as are today's machine tools. The formula is simple: Small workpiece = small clamping solution. Using the new small jaw module, about 80% of usual components are covered, and for larger components it can be easily changed over to a large jaw module within 30 seconds. The basic unit is a Spanntop chuck or Toplus chuck, now accepted as an excellent workholding device in its own right. So add to this the jaw module, clamping heads and mandrels; you achieve reliability, accuracy, and safety that traditional jaw chucks lack especially for I.D. clamping. Those who have experience with Hainbuch mandrels are aware of the unbelievable, even apparently impossible clamping situations that are feasible. Far better than using a 3 jaw chuck. The new jaw module now completes a clamping system that offers the right solution for the respective clamping situation, without compromise.

Jaw chuck Spanntop with new jaw module, size 215.

Key advantages:

- Simple, modular system oriented solution for fast clamping to aclamping range of 200 mm.

- Available in two sizes [144, clamping range from 25 - 115 mmand 215, clamping range from 25 - 200 mm]

- Minimal interference contour, proven technology, optimal utilization of the jaws

- Flexible, fast and repeatable set-up on clamping head or mandrel clamping

- Rigid workpiece clamping through the use of clamping head or mandrel

- Full bar size passage when using the clamping head

- Ideal for sensitive clamping and delicate components

- Can be used as a pick-up chuck on sub spindles

- Easy to maintain and impervious to contamination thanks to excellent guideway seal

- Also excellently suited for stationary use

Responsible for the content of this press release: HAINBUCH GmbH