hello to all the pro-builder here

i need some advise, im planning to build a 2'x4'x8" router, able to machining pvc sheet range to some steel plate, my question is the frame rigidity, wat material should i use? please advise

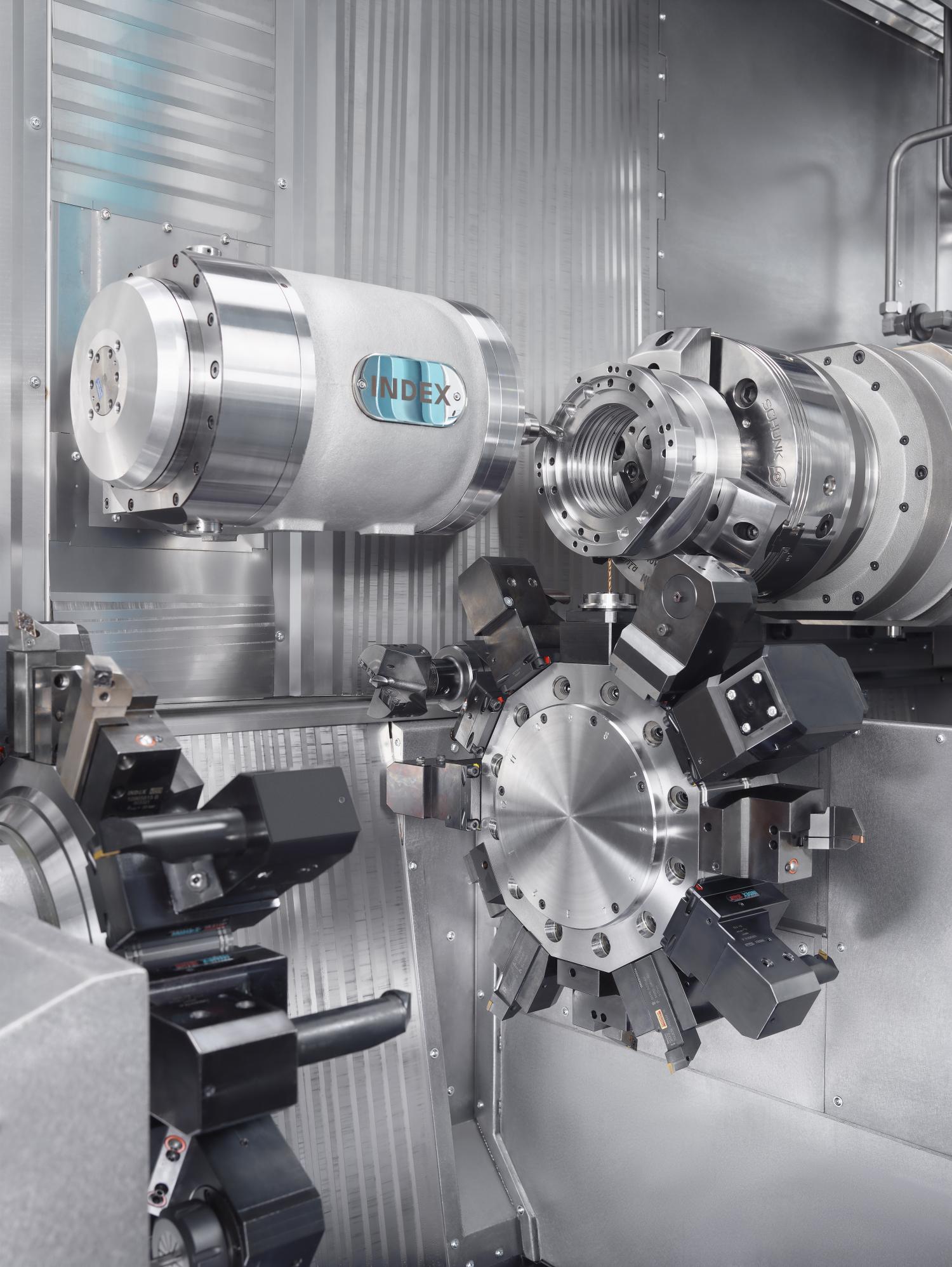

INDEX

Forum

Thread: cnc router frame, steel or alu?

Results 1 to 20 of 22

-

06-30-2010, 01:12 AM #1

Registered

Registered

- Join Date

- Jan 2010

- Posts

- 20

cnc router frame, steel or alu?

-

06-30-2010, 09:09 AM #2

Registered

Registered

- Join Date

- Oct 2008

- Posts

- 199

Hi Mate,

Not that I'm a pro builder....or pro anything for that matter

I guess it all comes down to the steel plate you want to cut.

What thickness steel plate do you have in mind?

How many passes would you be happy cutting that thickness plate?

When you say Aluminium, are you refering to an extrusion like the 80/20 system?

If so, one thing the 80/20 system has goining for it is the ease of assemley if tools are limited, however it can get expensive on a larger machine.

I've only cut steel on a manually operated drill/mill, someone with router/ steel cutting experience should give you some further advise.

Liam.

-

06-30-2010, 09:18 AM #3

Registered

Registered

- Join Date

- Jan 2010

- Posts

- 20

hi and thanks for reply

the thickness like 1/2" but i really dont mind how many pass it will have to run, ofcourse i will be happier if it can do cut with lesser pass

the structure i will use steel flat bar 3/8" thick, plus angle at the join

i had google a lot and i see ppl dont mill steel with router, why? bcuz linear shaft not rigid as slide?

-

06-30-2010, 09:33 AM #4

Registered

Registered

- Join Date

- Jan 2010

- Posts

- 20

not finish yet but i think this will give u better idea wat im talking

-

06-30-2010, 09:39 AM #5

Registered

Registered

- Join Date

- Oct 2008

- Posts

- 199

1/2" steel plate is getting pretty serious for a router, Maybe you should do a few sketches or CAD drawings and post them for people to comment on.

I think 1/2" steel will need a Steel Router to answer the first question.

Liam.

-

06-30-2010, 10:19 AM #6

Registered

Registered

- Join Date

- Jan 2010

- Posts

- 20

i tot with more pass it will still do the job will it? ie mill away 1" of steel with thickness 1/2" with 50 pass, or may be 100 pass? im not a machinist i never mill any metal, my job is totally unrelated to machining, i have very limited knowledge.

-

06-30-2010, 10:39 AM #7

Registered

Registered

- Join Date

- Oct 2008

- Posts

- 199

Sorry to say this but, that does not look rigid enough to machine steel plate.

I would think a heavy wall RHS 100x 50x 6mm, rather than 3/8 flat bar.

The gantry will only be stiff in the longitudinal axis....side to side it will flex and allow for vibrations.

If you look at a milling machine for inspiration, They are very heavy to absorb vibration....you could fill the RHS with sand, this will absorb high frequency vibrations much better than 3/8 flat bar.

What is your budget for this router?

What do you intend to use for a spindle?

Liam.

-

06-30-2010, 10:51 AM #8

Registered

Registered

- Join Date

- Jan 2010

- Posts

- 20

budget like 2.5k usd for frame, balllscrew, and shaft only, (i found some taiwan ballscrew are really good price, still donno the quality yet) electronic will be gecko g540, stepper nema23 ,i hope it can handle this.. spindle might use some chinese onefor routing. for milling spindle i dont know yet. is 1hp enough for milling?

sorry for my bad english, im not english educated:withstupi

-

06-30-2010, 11:33 AM #9

Member

Member

- Join Date

- Apr 2007

- Posts

- 8082

Machining of steel is normally done with very heavy cast iron milling machines of the Bridgeport type knee mills due to the stresses involved. Rigidity is everything when it comes to getting a decent finish on steel. A wood router style machine can cut steel but it won't give good results due to chatter and resonances. It also has to take very shallow cut depths and maybe use what is known as "pecking" to cut it at all. A wood working router or spindle is the wrong device to be cutting steel. The bearings won't last very long and the RPMs are way too high.

You can probably find a used milling machine that will do a much better job for less than you can build one of these router machines and not be happy with the results or speed of completion. This type of wood router design is just not a good choice for milling steel for a lot of other reasons.

I have two milling machines and two wood routers. Buy the milling machine for steel and other metals. Build or buy a wood router for wood, and maybe light use on aluminum, but no hard metals. You'll be glad you did.

CarveOneCarveOne

http://www.carveonecncwoodcraft.com

-

06-30-2010, 11:39 AM #10

Registered

Registered

- Join Date

- Oct 2008

- Posts

- 199

don't worry, you Engish is MUCH better than my Bengali!

don't worry, you Engish is MUCH better than my Bengali!

I think you need to do some more research, Feedrate for steel is much lower than what you will require for PVC, so small Nema 23 steppers geared down for steel may burn pvc at slow feedrate.Also spindle speed for steel will be slower for steel than for PVC, You may be able to use a (cheaper) slower speed spindle for the steel and save some $$ even second hand from old milling machine.

You will need to think, will I use this router for 80% pvc, 20% steel.

or.... 20% steel, 80% PVC.....or 50% 50%

Another alternative is to find a large Mill and convert to CNC.

Liam

-

06-30-2010, 11:55 AM #11

Registered

Registered

- Join Date

- Oct 2008

- Posts

- 199

Thanks for that Carveone

LCY, You are really talking two different machines.

Infact in the time a router type machine will cut steel, you could have done it on a manually operated mill with much better results.

As for your budget, it's hard to put in to perspective....i'm sure your dollar goes much further for manufacturing in Bangladesh than in Australia or the US.

I have cut PVC on a mill, allthough not ideal....it works. You should be building a machine with steel in mind.....the key, MASS

Liam

-

06-30-2010, 12:05 PM #12

Registered

Registered

- Join Date

- Jan 2010

- Posts

- 20

thanks both of you this is really a good place to learn

i guess its clear now, i will get a used mill later, but for this router, i should able to mill alumium, right?

i got a plan if this router works, i will make a second machine which will cut acrylic with laser, will build the frame with aluminium, so i can save a bit more than the first machine

-

06-30-2010, 12:16 PM #13

Registered

Registered

- Join Date

- Oct 2008

- Posts

- 199

"i guess its clear now, i will get a used mill later, but for this router, i should able to mill alumium, right? "

Not with 3/8" flat bar, No, You must build this as rigid as you can possibly afford!

-

06-30-2010, 12:32 PM #14

Registered

Registered

- Join Date

- Jan 2010

- Posts

- 20

how can i make the gantry more ridgid? http://www.cnccookbook.com/CCMillEpoxyFill.htm

im not sure how to weld the RHS u mentioned, at the right place accurately. i planned to pass the drawing to workshop so they can drill and tap hole for me, then i simply bolt them on... this is simple for me

-

06-30-2010, 12:36 PM #15

Registered

Registered

- Join Date

- Oct 2008

- Posts

- 199

Another thought, Could you use a plasma cutter for the steel ( if only 2D) and high speed spindle for plastics and possibly aluminium?.....all on the same router/plasma table.

Just a thought

Liam

-

06-30-2010, 12:46 PM #16

Registered

Registered

- Join Date

- Oct 2008

- Posts

- 199

I think you need to talk more to your workshop, they will have a good idea how to build your machine with the tools they have available and also may give you lots of ideas for design.

Liam.

-

06-30-2010, 02:12 PM #17

Registered

Registered

- Join Date

- Jan 2010

- Posts

- 20

i dont have a workshop yet, i will need a cnc router to start my own bussiness, thats why i want a good router build, which can makes more $$$

my job is modelling scaled houses, factory, or tower, all we use is pvc sheet(cut/engrave with engraver), acrylic sheet(laser cut/engrave), seldom use wood.. those are light weight material, but i still need a good router that will last longer like those commercial one.

for steel cutting, i prefer milling machine, i can build something for my personal use, hobby etc.

-

07-01-2010, 12:58 AM #18

Registered

Registered

- Join Date

- Oct 2008

- Posts

- 199

Have you considered building a proven design JGRO or Joe2006, perhaps using linear rail instead of plain bearings.

You could be making $$ with your machine sooner, rather than starting from scratch on a new design.

Even for PVC sheet I think you should strengthen the uprights on your gantry.

Do some more research on machines others have built here and copy what they have done......there's no point in reinventing the wheel!

-

07-01-2010, 02:19 AM #19

Registered

Registered

- Join Date

- Jan 2010

- Posts

- 20

i will use support linear shaft and bearing, cant effort linear rail and block

http://www.cnczone.com/forums/showthread.php?t=92565

-

07-01-2010, 12:34 PM #20

Registered

Registered

- Join Date

- Oct 2008

- Posts

- 199

That looks like a good deal on Gio666 machines.

Also check this out about castcnc for joes router

http://www.castcnc.com/index.html

and a thread here about the samehttp://www.cnczone.com/forums/showth...=103955&page=4

Similar Threads

-

My Steel Frame Router

By epineh in forum CNC Wood Router Project LogReplies: 484Last Post: 07-06-2009, 03:27 AM -

My steel frame router

By Spiv in forum DIY CNC Router Table MachinesReplies: 18Last Post: 06-19-2009, 12:14 AM -

Steel Frame 2' x 4' Router

By ksubenny in forum Open Source CNC Machine DesignsReplies: 10Last Post: 08-25-2008, 10:47 AM -

Steel Frame CNC Wood Router

By CNC Rocks in forum DIY CNC Router Table MachinesReplies: 12Last Post: 08-11-2008, 05:13 PM -

My 2nd Steel Frame Router

By epineh in forum CNC Wood Router Project LogReplies: 12Last Post: 07-12-2007, 08:35 AM

Reply With Quote

Reply With Quote