Hello,

Long time listener, first time caller. Thank you for reading my post.

I have just finished building an Avid CNC Pro inspired machine. When the motors are powered and jogging or running NC code, the machine shakes rather violently and this results in poor cuts. When the motors are not powered and the pinions are engaging the rack, I can smoothly push the gantry and Z axis. From my limited understanding I believe this is related to torque/resolution? In hind sight perhaps I should have used smaller (4.8 / 9 nm?) motors?

- This machine uses 2 x Nema 34 StepperOnline 12nm motors (https://www.ebay.com.au/itm/17550849...r=474833141429) (StepperOnline CL86T kit) on the Y axis and 1 x Nema 34 StepperOnline 12nm motor on the X axis.

- The power supply for the Nema 34's is 350 watt 60 volt.

- The CL86T's dip switches are set to 2000 steps per revolution, closed loop control, PUL/DIR single pulse, brake output

- The CL86T's alarm is not wired in

- The Nema 34's direct drive (no spring loading, either) MOD 2.0 30 tooth pinions.

- The OD of the 30 tooth pinions is 64mm.

- The 30 tooth pinions drive along MOD 2.0 racks.

I just ordered 3 x MOD 2.0 20 tooth pinions. The OD of these 20 tooth pinions is 43.5mm.

I am now looking at buying StepperOnline's Nema 34 planetary gearboxes (https://www.ebay.com.au/itm/17496428...r=474111496925). I want to achieve 50/50 with speed and accuracy. Can you please recommend what reduction I should try? There is 5:1, 10:1, 20:1 and 50:1.

I am hopeful this smaller 20 tooth pinion coupled with a planetary gearbox will increase the resolution/torque and the Nema 34's wont be stalling/shaking?

When the Nema 34's are powered on and stationary I can move the gantry very slightly pushing or pulling. I thought perhaps the pinions were not engaging the rack properly which allowed me to do this but after discussing this with the company I bought the 20 tooth pinions from, they said that this was typical behavior of Nema 34's. Does that sound right to you? I am quite disappointed if that is the case. Is this preventable?

Also, I could not for the life of me work out the Mach3 steps per mm for my machine. Can you please help me? Can you please explain the formula?

Any help is greatly appreciated. Thank you!

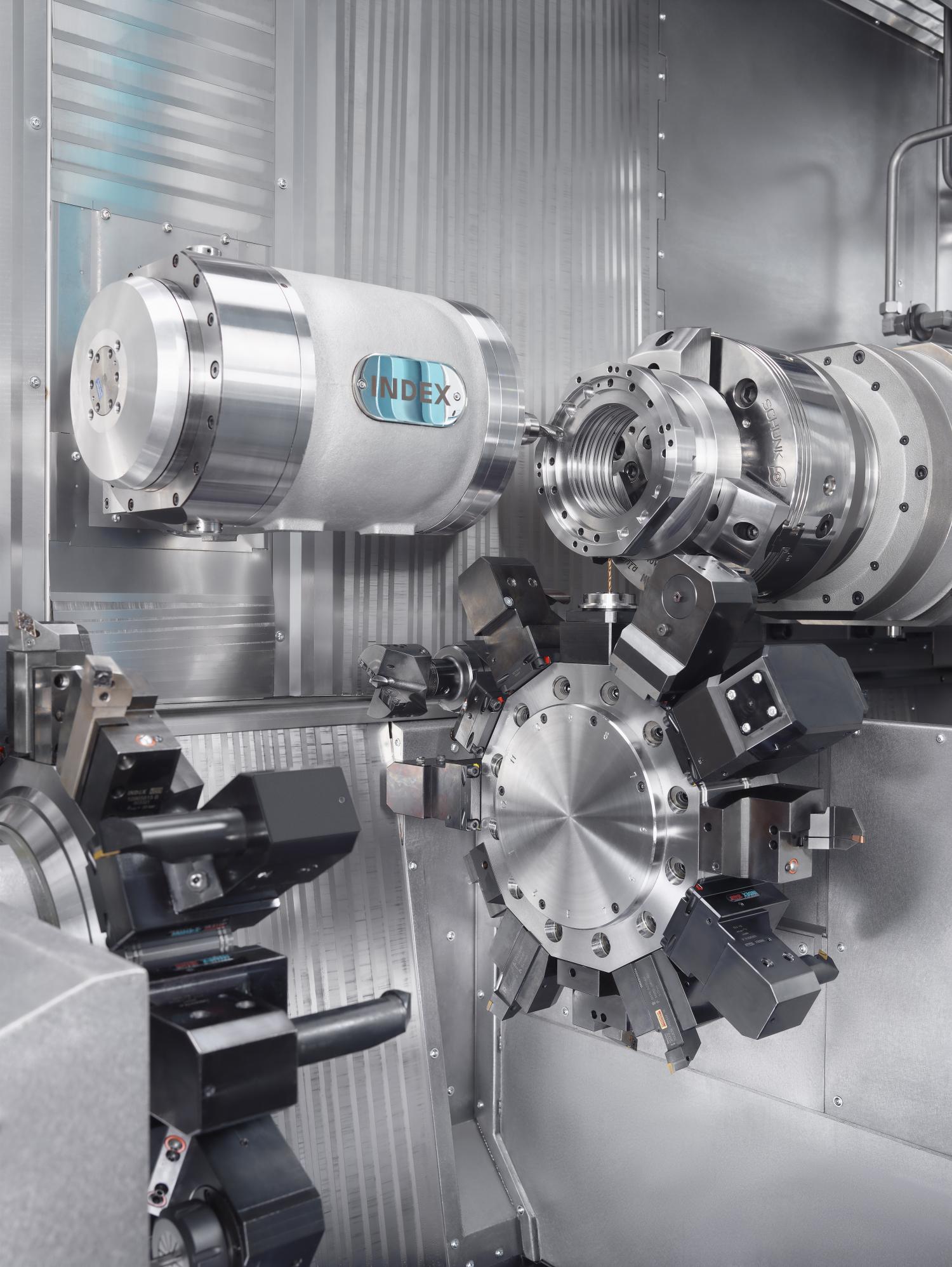

INDEX-Werke // INDEX TRAUB

Forum

Results 1 to 1 of 1

-

01-31-2024, 10:48 AM #1

Registered

Registered

- Join Date

- Jun 2013

- Posts

- 1

Having StepperOnline Nema 34 12nm motor torque related issues. Any advice appreciated

Similar Threads

-

StepperOnline.com NEMA 23 "kit" issues

By hitechwaynew in forum Stepper Motors / DrivesReplies: 12Last Post: 03-28-2024, 10:17 AM -

HBS860H NEMA 34 12NM closed loop system motor stuck after 3-5 seconds and alarm mode

By burgija1213 in forum Stepper Motors / DrivesReplies: 5Last Post: 08-15-2021, 06:23 PM -

HBS860H NEMA 34 12NM closed loop system motor stuck after 3-5 seconds and alarm mode

By burgija1213 in forum Stepper Motors / DrivesReplies: 0Last Post: 12-10-2020, 09:22 AM -

HBS860H NEMA 34 12NM closed loop system motor stuck after 3-5 seconds and alarm mode

By burgija1213 in forum Uncategorised MetalWorking MachinesReplies: 0Last Post: 12-09-2020, 06:02 PM -

NEMA 42 vs 34 12nm Steppers

By brumby in forum Stepper Motors / DrivesReplies: 4Last Post: 10-19-2011, 01:24 PM

Reply With Quote

Reply With Quote