I have built a CNC router / mill as a test bed to start and develop a special purpose machine. I chose Eding CNC as a control supplier and picked the 310 starter board. I am not new to machine building and have a mechanical background with some panel wiring experience.

My issue is that I have the machine powered up - I have all the drives woring - I can get them to jog and have all configured to home (in the correct direction) but I have fallen at the most basic hurdle - the home switch and the more I look the more confused I am.

The 310 is mounted on the 'breakout board' and at 'H1' I have simply fitted a micro switch across the + / -. But it doesn't work in any of the soft configurable options. I see a mention in the manual that it is a 'digital input'?. The diagram in the 310 hardware manual shows the switch between ground and the input (single input?, if that is + then what if anything goes in the - terminal?)

Now I could just go with software limits for home but I have many years of experience that tells me to do it properly. To that end a proper ES relay will be fitted to isolate drives / spindle.

Any help appreciated. Eding have made it clear that they don't help at this level...

Thanks,

Dave4J

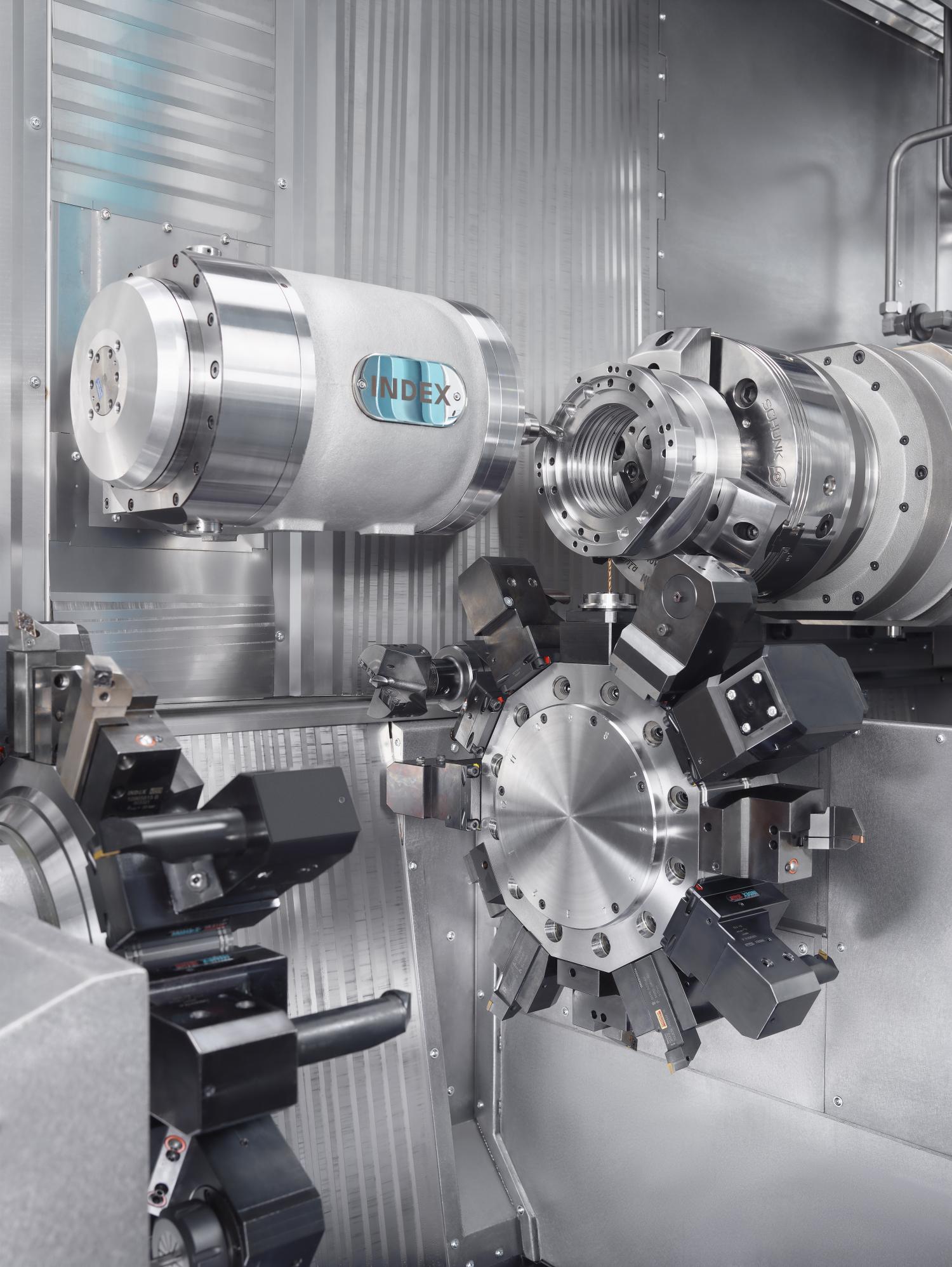

INDEX-Werke // INDEX TRAUB

Forum

Thread: Eding CNC Help Please

Results 1 to 4 of 4

-

02-04-2024, 07:35 PM #1

Member

Member

- Join Date

- Feb 2024

- Posts

- 3

Eding CNC Help Please

-

02-05-2024, 05:56 AM #2

Member

Member

- Join Date

- Apr 2022

- Posts

- 135

Re: Eding CNC Help Please

Your digital input is waiting for a signal. You need to know what signal it waits for. If it waits for negative then you wire negative through the limit switch to the input on the board.

If you post the diagram of your board it would be more clear …

-

02-05-2024, 02:41 PM #3

Member

Member

- Join Date

- Feb 2024

- Posts

- 3

Re: Eding CNC Help Please

Vlod,

Hi, thanks. Please see the link for the manual, an image of the home detail and an image of the breakout board. I think I perhaps need an opto isolator board? The manual states 'digital input and max 5v'. I had it in my head that the indicated logic circuit was in the 'breakout board' but perhaps having a micro switch activating an opto-isolator and feeding +5v to the + terminal and ground the - terminal'.

The IO chart is half way down the manual, the Home 1 is a little further down.

Thanks again, this is all new to me and I haven't even got to running G code! Much appreciated.

https://docs.edingcnc.com/Hardware/c...ODY4Ny4wLjAuMA..

-

02-06-2024, 03:31 AM #4

Member

Member

- Join Date

- Apr 2022

- Posts

- 135

Re: Eding CNC Help Please

The manual said that you need negative signal to trigger your input

On the i/o chart it would be pins #18, 24, 25 ( they call them Ground)

Attach the wire to any of these pins and to your switch or switches on one side and from the other side of the switch it goes to your input.

Then in software you have to specify if it acts as a low or high. It depends if you use normally open or normally closed switch.

If you use normally open switch then you mark it as active low and if the switch normally closed you specify it as active high.

-

02-06-2024, 03:36 AM #5

Member

Member

- Join Date

- Apr 2022

- Posts

- 135

Re: Eding CNC Help Please

You can integrate optocouplers if you want… but it would complicate the schematic for you.

What software do you use with this card?

-

02-06-2024, 10:45 AM #6

Member

Member

- Join Date

- Feb 2024

- Posts

- 3

Re: Eding CNC Help Please

Vlod,

Thanks, I have it working now. Software is the same company - Eding CNC. They make boards that are built into many machines by original equipment manufacturers and the software looks to be very configurable. There are outlets for DIY in Germany but very few English speaking DIY users that I can find. Perhaps I should have picked Mach 3 just for the wider community support. But in the end, if I can figure out running and adapting the machine I want to build (or specify and buy) some special purpose machines, so I think good hardware / software / supplier will help in the future.

-

02-06-2024, 01:54 PM #7

Member

Member

- Join Date

- Apr 2022

- Posts

- 135

Re: Eding CNC Help Please

I’m glad you have it working.

Reply With Quote

Reply With Quote