Hi,

I have CNC machine with 4 axis.

X and Y are directional, A and B are rotational axis.

I made a simple g-code. I need constant feedrate on B axis.

Here is the code:

N1 FGROUP(B)

N2 F 5000.

N3 G01 G641 ADIS=50 G91 G94 F 5000. B= 1.819

N4 F 5000. B= 38.345 Y 53.88 A -7.98

N5 F 5000. B= 38.694 Y 88.50 A -7.81

N6 F 5000. B= 260.062 Y 560.73 A -1.53

N7 F 5000. B= 38.705 Y 15.27 A 9.35

N8 F 5000. B= 38.321 Y -11.38 A 7.97

N9 F 5000. B= 1.819

N10 F 5000. B= 38.346 Y -53.88 A 7.98

N11 F 5000. B= 38.693 Y -88.50 A 7.81

N12 F 5000. B= 260.062 Y -560.73 A 1.53

N13 F 5000. B= 38.706 Y -15.27 A -9.35

N14 F 5000. B= 38.321 Y 11.38 A -7.97

R4=R4+1

MSG("Layer "<<R104<<" Completed "<<R4<<" Of " <<R5)

IF R4<R5 GOTOB N1

I have a problem on a block N9 and N3 with a small feedrate glich. It is not much but it is making a lot of problems on the machine.

If I make the number bigger (from B=1.819 to about B=25) it seems the glich dissapears.

Any ideas how to fix it.

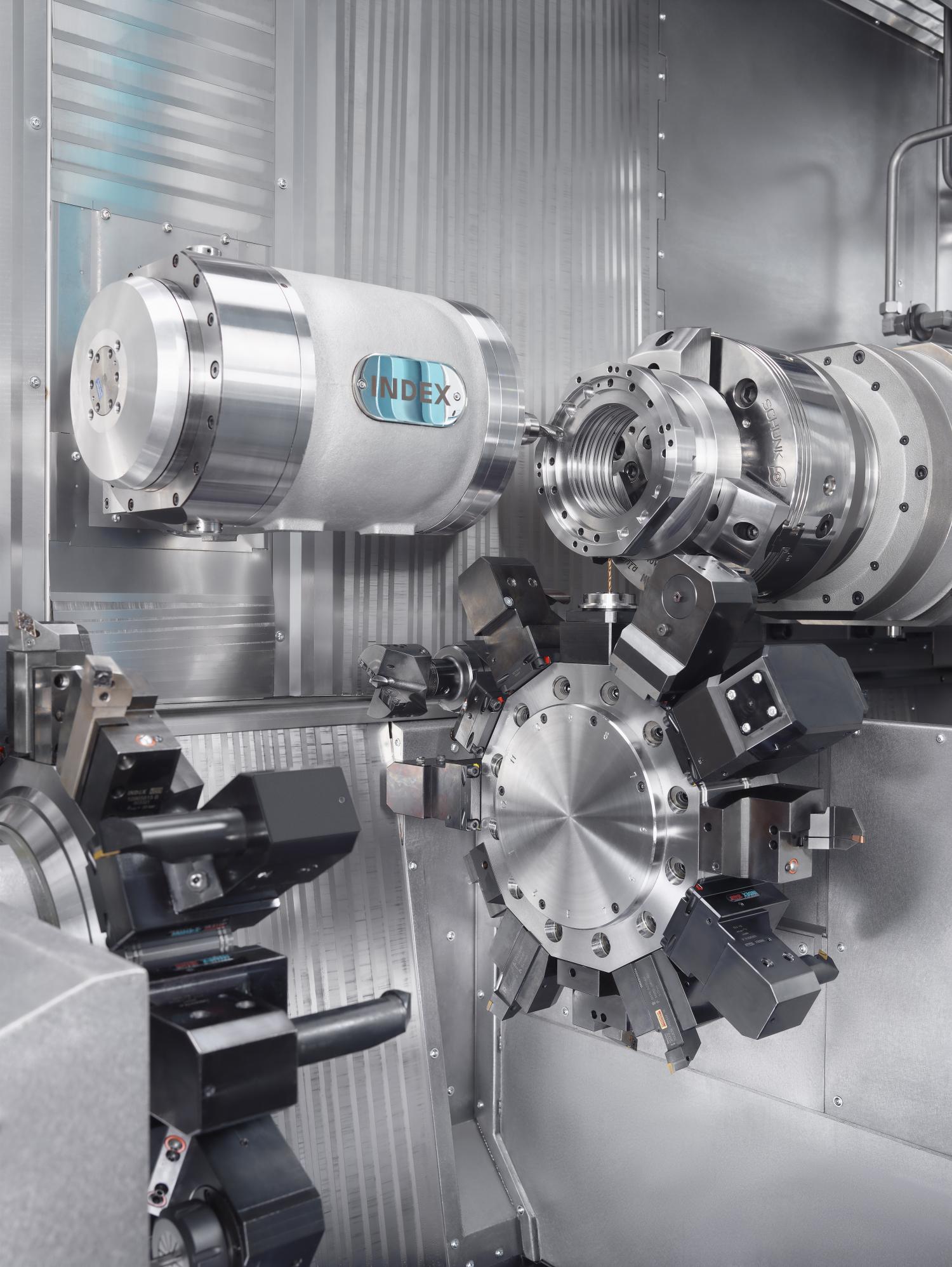

INDEX-Werke // INDEX TRAUB

Forum

Thread: Sinumerik 802D - rotary axis

Results 1 to 1 of 1

-

02-05-2024, 03:01 PM #1

Member

Member

- Join Date

- May 2014

- Posts

- 7

Sinumerik 802D - rotary axis

Reply With Quote

Reply With Quote