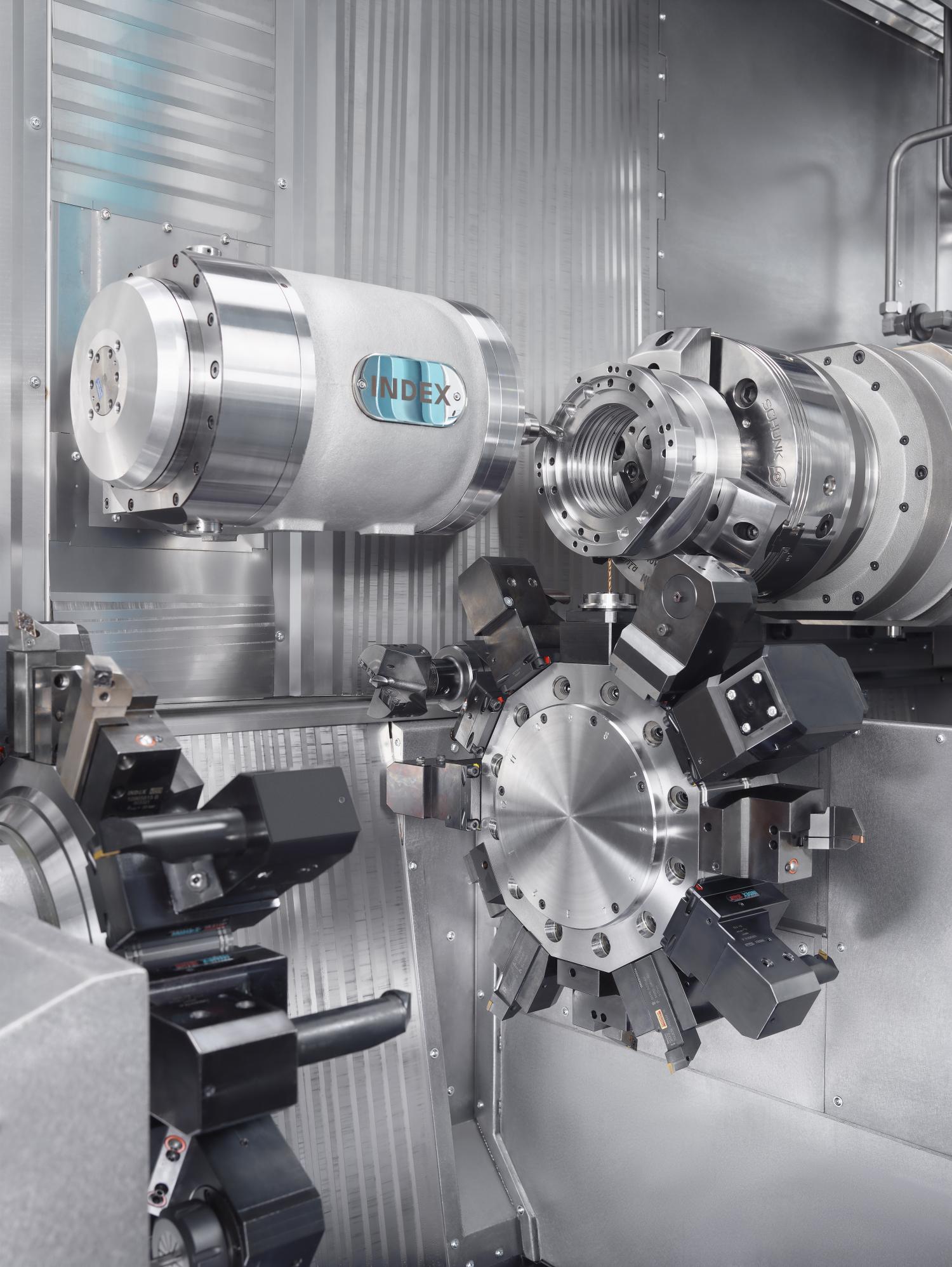

A new unveiling: the Esslingen turning machine manufacturer presents the INDEX G400, an innovative complete machining center suitable for parts up to 1600/2300 mm long. While its cousin, the INDEX G420, is equipped with a motorized milling spindle and a large tool magazine on its upper tool carrier, the INDEX G400 instead uses a VDI-40 turret with twelve stations and a quill that enables a Y stroke of ±100 mm.

But where would modern machine technology be without the right automation solution? The iXcenter robot cell is now available for the INDEX G400 and other machines of this size – in addition to integrated handling units. It can be used not only for loading and unloading large, heavy workpieces, but also for a range of upstream and downstream tasks.

Reduce setup times, cut unit costs

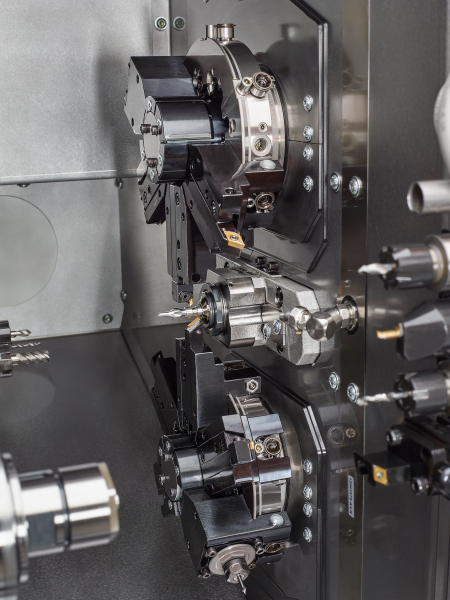

Also new is the second generation of the TRAUB TNL12, a sliding headstock automatic lathe that now, like its larger cousins, can be quickly converted to a fixed headstock. This machine features a more compact design and improved kinematics. In the production of small high-precision turned parts, this means greater productivity and flexibility with reduced space requirements.

A further highlight is the new CNC-controlled MS24-6 multi-spindle automatic lathe, the successor to the INDEX MS22-6 lathe. Slightly larger in maximum bar diameter, the MS24-6 is more compact overall and offers numerous features that ensure highly economical turning operations – fast and easy setup included. This offers a strong pay off, as it is not unusual for today’s contract lathe operator to have to convert their multi-spindle automatic lathes several times a week.

In the field of universal lathes, INDEX is expanding its range with the TRAUB TNA500, a powerful, robust machine with many practical features for everything from pilot runs to mid-volume production.

Digitization points the way forward

INDEX recognized the fundamental importance of digitization to the world of machining very early on, and years ago developed the cloud-based iXworld platform. The range of available apps grew at a rapid pace, all of which were incorporated into the INDEX iX4.0 IoT platform, which makes it possible for all production machines to be integrated in the digital environment. These software tools help to identify ongoing productivity losses, reduce unscheduled stoppages, and minimize downtimes. Anyone who would like to test it can join the digital world right now with the free introductory offer “iX4.0 go”.

In keeping with the times, INDEX has bundled and organized its numerous services covering all aspects of the machining process in the iXservices iXworld module. Of course, this does not mean that INDEX is now only available to customers online. Over 150 service engineers in Germany and service locations in more than 50 countries around the world are fully committed to taking care of customers’ concerns and their INDEX and TRAUB machines in person. Support is available via a hotline and, for even more efficiency, using the TicketManager and innovative remote support. And for matters that require the presence of an on-site service engineer, we will be on our way to assist as quickly as possible.

Germany

Germany