MAM-Automation GmbH

Products

Software for production and production planning

Manufacturing execution software (MES)

Data automation ? MMS

|

Manufacturing execution software (MES)

MAM Automation GmbH

Manufacturing execution software (MES)

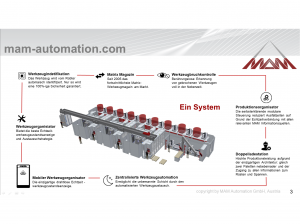

The software modules developed by MAM are the performance accelerator of your production and fundamentally increase your throughput. Starting point and main consideration is the job management, from which an optimized automated system control will be derived.

Every production phase becomes transparent and easy to plan with the MMS software:

Sequence control for automatic pallet and tool changes

Resource planning and order-related optimization

Tool management and monitoring

Provision of production data

Every production phase becomes transparent and easy to plan with the MMS software:

Sequence control for automatic pallet and tool changes

Resource planning and order-related optimization

Tool management and monitoring

Provision of production data

Software for managing manufacturing systems

Produktionsplaner 3.5

|

Software for managing manufacturing systems

MAM Automation GmbH

Software for managing manufacturing systems

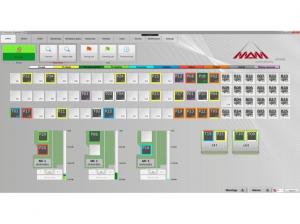

Production Organizer – flexible manufacturing made easy

This modular MMS software developed by MAM since 2007 enables advance planning of all orders, taking into account all resources such as machine hours, man hours, raw material, tools and fixtures. With the entire MAM manufacturing system and Production Organizer, you reduce your production lead time with less preparation. Dynamic production control enables real-time intervention in job scheduling without loss of productivity. Translated with DeepL

This modular MMS software developed by MAM since 2007 enables advance planning of all orders, taking into account all resources such as machine hours, man hours, raw material, tools and fixtures. With the entire MAM manufacturing system and Production Organizer, you reduce your production lead time with less preparation. Dynamic production control enables real-time intervention in job scheduling without loss of productivity. Translated with DeepL

Software for production planning and control (PPC)

PO - MAM Production Organizer

|

Software for production planning and control (PPC)

MAM Automation GmbH

Software for production planning and control (PPC)

Production Organizer – flexible manufacturing made easy

This modular MMS software, developed by MAM since 2007, enables the advance planning of all orders, taking into account all resources such as machine hours, man hours, raw material, tools and fixtures. With the entire MAM manufacturing system and the Production Organizer, you reduce your production lead time with less preparation effort. Dynamic production control allows you to interfere with job scheduling in real time without losing productivity.

This modular MMS software, developed by MAM since 2007, enables the advance planning of all orders, taking into account all resources such as machine hours, man hours, raw material, tools and fixtures. With the entire MAM manufacturing system and the Production Organizer, you reduce your production lead time with less preparation effort. Dynamic production control allows you to interfere with job scheduling in real time without losing productivity.

Tool management software

Tool Manger 3.1

|

Tool management software

MAM Automation GmbH

Tool management software

No waiting times, even in fully dynamic, flexible production.

The great advantage of the MAM tool management "Tool Manager" is obvious;

The complete solution from a single source with real-time connection to the MAM robots.

All tools and tool components are recorded centrally and synchronized with the MAM tool magazines or planetary systems in real time. In this way you can guarantee timely procurement even in dynamic production processes, plan the use of tools precisely and order new tools and components.

Particularly recommended in combination with the high-tech options (Industry 4.0):

>laser broken tool detection; Non-contact broken tool detection

>Taper cone cleaner (HSK, SK, BT, BigPlus)

>RFID tool identification or QR code tool identification

This is how you create a consistent system that only MAM can offer you

The great advantage of the MAM tool management "Tool Manager" is obvious;

The complete solution from a single source with real-time connection to the MAM robots.

All tools and tool components are recorded centrally and synchronized with the MAM tool magazines or planetary systems in real time. In this way you can guarantee timely procurement even in dynamic production processes, plan the use of tools precisely and order new tools and components.

Particularly recommended in combination with the high-tech options (Industry 4.0):

>laser broken tool detection; Non-contact broken tool detection

>Taper cone cleaner (HSK, SK, BT, BigPlus)

>RFID tool identification or QR code tool identification

This is how you create a consistent system that only MAM can offer you

Tool monitoring systems

Laser broken tool detection

|

Tool monitoring systems

MAM Automation GmbH

Tool monitoring systems

Main time parallel - not a second loss of processing time

Non-contact – no tool edge damage

Integrated- Connected via MAM Tool manager to customers ERP System

safe - due option Tool-RFID

The tool control system controls the tool length without contact and this parallel to the main machining time on the machine, without losing even a second of processing time.

Laser measurement enables reliable and precise drill breakage control, which is a great advantage especially for small diameters e.g. M2. The laser is completely encapsulated and protected against contamination with sealing air, even when it is working. This is a valuable auxiliary tool in low-manned and unmanned production. In cooperation with the tool service life management and the sister tool management, for example, if a drill breaks, an immediate reaction can be made to the next subsequent threading tool.

Non-contact – no tool edge damage

Integrated- Connected via MAM Tool manager to customers ERP System

safe - due option Tool-RFID

The tool control system controls the tool length without contact and this parallel to the main machining time on the machine, without losing even a second of processing time.

Laser measurement enables reliable and precise drill breakage control, which is a great advantage especially for small diameters e.g. M2. The laser is completely encapsulated and protected against contamination with sealing air, even when it is working. This is a valuable auxiliary tool in low-manned and unmanned production. In cooperation with the tool service life management and the sister tool management, for example, if a drill breaks, an immediate reaction can be made to the next subsequent threading tool.