MAM-Automation GmbH

Products

Workpiece and tool handling

Handling of workpieces

Pallet Automation

|

Handling of workpieces

MAM Automation GmbH

Handling of workpieces

Find your Pallet Automation System. Different requirements demand different accesses.

A system that links several machines together and also is able to produce unmanned at weekends? Well-coordinated machining processes – different batch sizes for major customers and always an eye on unit costs and throughput times – after all, process cost optimization is your constant companion.

Extreme lack of space and yet you need 16 pallet places or more for your 4- or 5-axis horizontal machining center and maybe your workpiece weights will increase in the future. This pallet system can be used where it was not considered possible.

A system that links several machines together and also is able to produce unmanned at weekends? Well-coordinated machining processes – different batch sizes for major customers and always an eye on unit costs and throughput times – after all, process cost optimization is your constant companion.

Extreme lack of space and yet you need 16 pallet places or more for your 4- or 5-axis horizontal machining center and maybe your workpiece weights will increase in the future. This pallet system can be used where it was not considered possible.

Palletising of workpieces and tools

Flexible Pallet Automation

|

Palletising of workpieces and tools

MAM Automation GmbH

Palletising of workpieces and tools

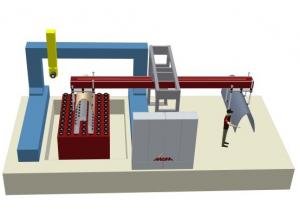

MAM is known for reliable, powerful, flexible manufacturing systems.

The high-performance pallet system HPPS with its components is clearly assigned to the family of machine tools and is adapted to customer requirements on a project basis. Center is the MAM cell controllerof and the MAM robots, which are controlled by an automation computer without moving parts.

The modular control platform from MAM (Production Organizer) enables the control and interaction of multiple robots. In this way, complex chains of machine tools can be implemented, which clearly distinguishes MAM from the competition.

The matrix magazines from MAM set standards in terms of storage density and speed, but only the interaction with a MAM-HPPS pallet system unleashes the potential of this system.

Realize more flexible manufacturing systems for aerospace, engine, turbine and agricultural parts with MAM!

The high-performance pallet system HPPS with its components is clearly assigned to the family of machine tools and is adapted to customer requirements on a project basis. Center is the MAM cell controllerof and the MAM robots, which are controlled by an automation computer without moving parts.

The modular control platform from MAM (Production Organizer) enables the control and interaction of multiple robots. In this way, complex chains of machine tools can be implemented, which clearly distinguishes MAM from the competition.

The matrix magazines from MAM set standards in terms of storage density and speed, but only the interaction with a MAM-HPPS pallet system unleashes the potential of this system.

Realize more flexible manufacturing systems for aerospace, engine, turbine and agricultural parts with MAM!

Tool changers and magazines

MAM CTA Central Tool Automation

|

Tool changers and magazines

MAM Automation GmbH

Tool changers and magazines

MAM – CTA | Central Tool Automation

Gantry loader Robot – flexible linking of magazines

The portal robot system CTA is designed for the flexible, fast, space-saving and a central supply and administration of tools. It communicates with all MAM matrix magazines, MAM pallet systems and all MES and ERP systems and thus enables absolute flexibility in unmanned production shifts.

Linear Robot: Speed: 10m/sec

Gantry loader Robot – flexible linking of magazines

The portal robot system CTA is designed for the flexible, fast, space-saving and a central supply and administration of tools. It communicates with all MAM matrix magazines, MAM pallet systems and all MES and ERP systems and thus enables absolute flexibility in unmanned production shifts.

Linear Robot: Speed: 10m/sec

MAM Matrix Werkzeugmagazine

|

Tool changers and magazines

MAM Automation GmbH

Tool changers and magazines

Tool magazines and tool automation

The best solution, without compromise

For highly automated production, high tool availability is critical. A magazine with high storage capacity is the only solution to reduce unproductive time. MAM has the fastest matrix magazines on the market. Thanks to a graphical user interface and tool management with the necessary real-time monitoring and automated loading strategy, your MAM magazines are always well equipped. MAM also offers the widest range of magazine types. Our 2-axis and 4-axis robots, which have been continuously developed for tool handling since 2004, ensure unparalleled performance, high availability and low maintenance costs. Translated with DeepL

The best solution, without compromise

For highly automated production, high tool availability is critical. A magazine with high storage capacity is the only solution to reduce unproductive time. MAM has the fastest matrix magazines on the market. Thanks to a graphical user interface and tool management with the necessary real-time monitoring and automated loading strategy, your MAM magazines are always well equipped. MAM also offers the widest range of magazine types. Our 2-axis and 4-axis robots, which have been continuously developed for tool handling since 2004, ensure unparalleled performance, high availability and low maintenance costs. Translated with DeepL

MAM-C

|

Tool changers and magazines

MAM Automation GmbH

Tool changers and magazines

MAM-C

Only three square meters of floor space and changing times of 4.8 seconds thanks to the patented robots.

The MAM-C is the most compact magazine and fits almost any horizontal machining center without modifications. The tool change times of a magazine with e.g. 360 HSK-63 storage locations are only 4.8 to 9 seconds due to the patented robot. The acceleration of the two main axes is higher than the force of gravity! The MAM-C was launched on the market in 2007, first and second generation magazines have already produced several million tool changes in tough industrial use.

Only three square meters of floor space and changing times of 4.8 seconds thanks to the patented robots.

The MAM-C is the most compact magazine and fits almost any horizontal machining center without modifications. The tool change times of a magazine with e.g. 360 HSK-63 storage locations are only 4.8 to 9 seconds due to the patented robot. The acceleration of the two main axes is higher than the force of gravity! The MAM-C was launched on the market in 2007, first and second generation magazines have already produced several million tool changes in tough industrial use.

MAM-C50-205

|

Tool changers and magazines

MAM Automation GmbH

Tool changers and magazines

Only three square meters of floor space and changing times of 8 seconds thanks to the patented robots.

The MAM-C is the most compact magazine and fits almost any horizontal machining center without modifications. The tool change times of a magazine ar the lowest of such magazines due to the patented robot. The acceleration of the two main axes is higher than the force of gravity! The MAM-C was launched on the market in 2007, first and second generation magazines have already produced several million tool changes in tough industrial use.

Main Model:

MAM-C50-205 / CAT50, BT 50, SK 50,HSK 100, Capto C10

The MAM-C is the most compact magazine and fits almost any horizontal machining center without modifications. The tool change times of a magazine ar the lowest of such magazines due to the patented robot. The acceleration of the two main axes is higher than the force of gravity! The MAM-C was launched on the market in 2007, first and second generation magazines have already produced several million tool changes in tough industrial use.

Main Model:

MAM-C50-205 / CAT50, BT 50, SK 50,HSK 100, Capto C10

MAM-L typrow

|

Tool changers and magazines

MAM Automation GmbH

Tool changers and magazines

MAM-L the DESIGN ICON

12 models, MAM built hundreds since 2004, many faild copies from many compeditors - many great compliements.

4-fold tool turret, carousel loading station.

In the search for the optimal solution, MAM makes no compromises. The ratio of magazine size to number of tools is phenomenal; More than 1000 tools with HSK-63 holder fit in a MAM-L40 with a footprint of just 1.3 by 4.7 meters! In order to meet all requirements, 12 models are available for this series, which has been built since 2004. The integrated logistics software automatically reads the next 3 tools from the CNC program and saves them in the tool turret. So you are always prepared!

preferred models:

MAM-L40-603* / CAT40, BT 40, SK 40, HSK 63, Capto C6

MAM-LD-628* / CAT50, BT 50, SK 50, HSK 100, Capto C10

12 models, MAM built hundreds since 2004, many faild copies from many compeditors - many great compliements.

4-fold tool turret, carousel loading station.

In the search for the optimal solution, MAM makes no compromises. The ratio of magazine size to number of tools is phenomenal; More than 1000 tools with HSK-63 holder fit in a MAM-L40 with a footprint of just 1.3 by 4.7 meters! In order to meet all requirements, 12 models are available for this series, which has been built since 2004. The integrated logistics software automatically reads the next 3 tools from the CNC program and saves them in the tool turret. So you are always prepared!

preferred models:

MAM-L40-603* / CAT40, BT 40, SK 40, HSK 63, Capto C6

MAM-LD-628* / CAT50, BT 50, SK 50, HSK 100, Capto C10

MAM-LX

|

Tool changers and magazines

MAM Automation GmbH

Tool changers and magazines

MAM-LX

Compact, powerful and flexible

Innovative design with proven components from the L and XX series lead to maximum reliability, flexibility and efficiency. This magazine was developed to cover the most diverse customer requirements from prototype production to series production. The powerful 4-axis robot from MAM guarantees fast change-over times with tool weights of up to 50 kg. Over 400 tools with HSK-100 holder, all up to 800mm fit into a MAM-LX with only 1.5 x 6 meter footprint!

Perfered model:

MAM-LX-412 / CAT50, BT 50, SK 50, HSK 100, Capto C10

Compact, powerful and flexible

Innovative design with proven components from the L and XX series lead to maximum reliability, flexibility and efficiency. This magazine was developed to cover the most diverse customer requirements from prototype production to series production. The powerful 4-axis robot from MAM guarantees fast change-over times with tool weights of up to 50 kg. Over 400 tools with HSK-100 holder, all up to 800mm fit into a MAM-LX with only 1.5 x 6 meter footprint!

Perfered model:

MAM-LX-412 / CAT50, BT 50, SK 50, HSK 100, Capto C10

MAM-XX

|

Tool changers and magazines

MAM Automation GmbH

Tool changers and magazines

MAM-XX

The reliable solution for tools with a length of 1.5 meters and a max. tool weight of 70 kg

To meet the special requirements of the large-scale machine automation, MAM has developed the XX type. It is a reliable high-performance system for tools up to 1500 mm and weights up to 70 kg. Handling such tools in space-saving storage is only possible thanks to MAM’s decades of experience with tool magazines.

prefered model;

MAM-XX-50,4 / CAT50, BT 50 (bigPlus), SK 50, HSK 100, Capto C10

The reliable solution for tools with a length of 1.5 meters and a max. tool weight of 70 kg

To meet the special requirements of the large-scale machine automation, MAM has developed the XX type. It is a reliable high-performance system for tools up to 1500 mm and weights up to 70 kg. Handling such tools in space-saving storage is only possible thanks to MAM’s decades of experience with tool magazines.

prefered model;

MAM-XX-50,4 / CAT50, BT 50 (bigPlus), SK 50, HSK 100, Capto C10

Transfer facilities

Transfersysteme

|

Transfer facilities

MAM Automation GmbH

Transfer facilities

Special transfer systems can be efficiently implemented by MAM because the movement module of the logistics software (PO or TO) also works allene. Thus, connections to ERP systems are still possible.

An example project; Flex Ram -The complete system

The software-supported automated FLEXram production allows an enormous reduction of the Rüstzeiten and thus production costs. The servo-driven ram system is controlled and automatically loaded and unloaded by the MAM Production Organizer.

The FLEXram coordinates and CNC programs are automatically generated by the postprocessor of the CAM system and retrieved by the MAM system. The current clamping status is taken into account. Even small, individually tailored quantities can be produced cost-effectively. Translated with DeepL

An example project; Flex Ram -The complete system

The software-supported automated FLEXram production allows an enormous reduction of the Rüstzeiten and thus production costs. The servo-driven ram system is controlled and automatically loaded and unloaded by the MAM Production Organizer.

The FLEXram coordinates and CNC programs are automatically generated by the postprocessor of the CAM system and retrieved by the MAM system. The current clamping status is taken into account. Even small, individually tailored quantities can be produced cost-effectively. Translated with DeepL