8

Followers

Supplier

System 3R International AB

Sorterargatan 1

162 50 Vällingby

Service Spectrum: Represented in 10 categories

Contact persons

Dick OttossonHead of Product Management

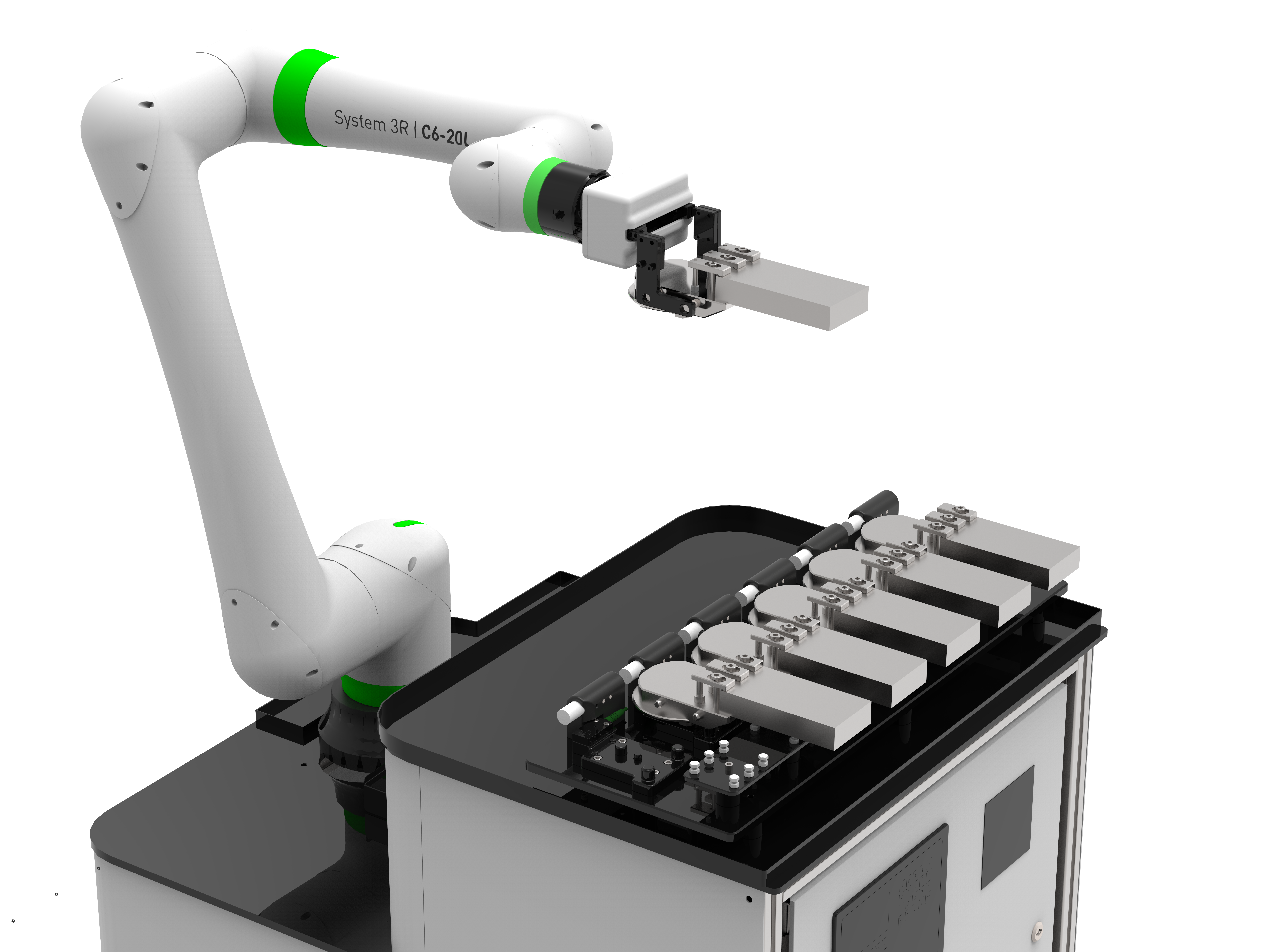

Dick OttossonHead of Product Management- Collaborative Robot (Cobot)

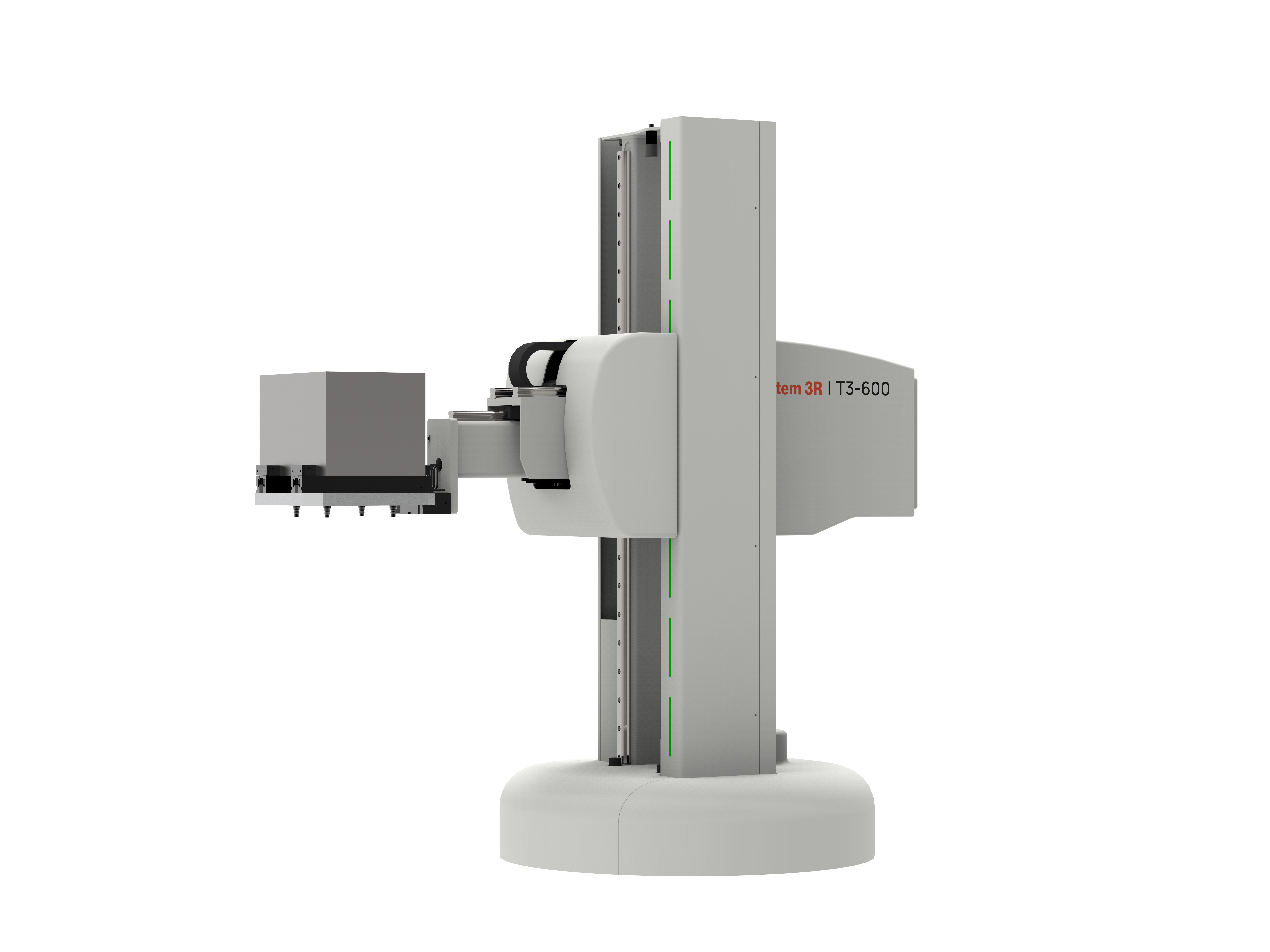

- Manipulating robots

- Automated guided vehicles

- Software for managing manufacturing systems

- Software for capacity and production date scheduling

- Handling of workpieces

- Zero point clamping systems

- Vacuum fixing plates

- Magnetic plates

- Chucking systems

- Tool systems, modular

Patrick KrebsOEM sales

Patrick KrebsOEM sales- Tool systems, modular

- Chucking systems

- Magnetic plates

- Vacuum fixing plates

- Zero point clamping systems

- Software for capacity and production date scheduling

- Software for managing manufacturing systems

- Handling of workpieces

- Automated guided vehicles

- Manipulating robots

- Collaborative Robot (Cobot)

Per NilssonOEM Sales Manager

Per NilssonOEM Sales Manager- Tool systems, modular

- Chucking systems

- Magnetic plates

- Vacuum fixing plates

- Zero point clamping systems

- Software for capacity and production date scheduling

- Software for managing manufacturing systems

- Handling of workpieces

- Automated guided vehicles

- Manipulating robots

- Collaborative Robot (Cobot)

Newsfeed

About System 3R International AB

System 3R shall be the leading supplier of productivity-enhancing tools and knowledge for the manufacturing industry.

Your machines do not need to stand still for long while you set-up and prepare different jobs. Everything goes faster with fixed references. We call this concept One Minute Set-up!

By working with fixed references, System 3R converts internal set-up time to external set-up time. Our concept centres on defining each machine’s zero point once and once only. Fixed references for all machines and a common system for the entire workshop are then possible. Just like pit stops in Formula One, set-up times are reduced dramatically.

Palletisation is the first step towards automation. Combined with a reference system, this gives unbeatable accuracy. System 3R minimises downtime and connects production flows. The ultimate goal of reducing lead times is achieved!

Your machines do not need to stand still for long while you set-up and prepare different jobs. Everything goes faster with fixed references. We call this concept One Minute Set-up!

By working with fixed references, System 3R converts internal set-up time to external set-up time. Our concept centres on defining each machine’s zero point once and once only. Fixed references for all machines and a common system for the entire workshop are then possible. Just like pit stops in Formula One, set-up times are reduced dramatically.

Palletisation is the first step towards automation. Combined with a reference system, this gives unbeatable accuracy. System 3R minimises downtime and connects production flows. The ultimate goal of reducing lead times is achieved!