technotrans SE

Products

Thermal Management

Safety and environment

Recycling plants

toolsmart

|

Modular solution for the preparation and filtration of cooling lubricants

technotrans AG

Separators for coolants and lubricants, pumps, filters, centrifuges

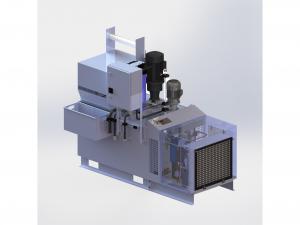

The toolsmart.line is a compact and modular solution for the preparation of cooling lubricants. It is characterised by its space-saving design and its ability to control numerous processes by way of a single control system. As a result, one single cooling system can supply several different manufacturing areas, for example. The result is a cost-efficient, resource-saving solution.

The heart of the toolsmart system is the filtration system. There are several different filtration modules for full flow, partial flow or bypass applications that can be combined as needed. The product portfolio ranges from the basic toolsmart.bt system up to the flexible toolsmart.xt unit with a tank capacity of up to 4,000 litres and a filtration rate of up to 750 l/min.

The toolsmart.cp is a combined spindle, control cabinet and cooling lubricant cooling system in a single unit. The modules are used in a central or distributed manner for a wide range of processes and can be complemented with additional components, including a temperature control unit or skimmer.

Water treatment, plants and components

moldclean

|

Efficient cleaning of soiled circuits combined with improved heat transfer

technotrans solutions GmbH

Wastewater purification, plants and components

Limescale and corrosion are unwanted factors with a negative effect on the overall productivity: They considerably reduce the heat transfer, process reliability and product quality. Originally developed for reducing the cooling time of moulded plastic parts, the moldclean system is now also successfully used in heat exchanger systems.

The units offer a convincing level of effectiveness: Depending on the degree of soiling, the cleaning of injection moulds leads to a cooling time reduction of up to 40%, and in some cases even more. Customers benefit from a higher level of process reliability and reduced operating costs. The robust and user-friendly solution is available as a cost-efficient starter model with one tank and as an operating-cost-optimised variant with two tanks. Optional automatic ball valves can be used for switching between the cleaning cycles.

The moldclean unit can clean up to 8 temperature control circuits simultaneously.