technotrans SE

ProductsThermal Management

spray.xact 5000

|

Large-format airless spray lubrication

technotrans AG

Other oiling and greasing systems

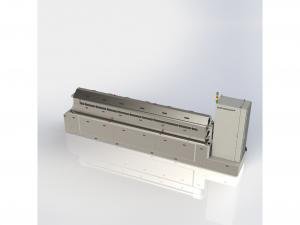

Up to 2 x 48 nozzles for a maximum spraying width of 4,800 mm ? those are the dimensions for which spray.xact 5000 was created. The special spray lubrication system for large presses provides for airless and economical oil application to blanks which are the preferred solution for the outer skin panels of vehicle bodies.

The heart of the system is the proprietary spray valve developed by technotrans. It is electronically controlled and emits spray pulses. Thanks to a high spraying frequency, the result is a constant and homogeneous spray pattern on the sheet metal surface. There is also no need for an extraction system. The oil quantity can be adjusted precisely simply by changing the spraying parameters. In addition, adjustment is completely straightforward due to the fact that it is 100% electronically controlled.

Furthermore, spray.xact 5000 excels thanks to its easy access to all of the components for maintenance or in the event of malfunctions and straightforward installation of key components for the emergency mode.

spray.xact food

|

Efficient spray lubrication for the food industry

technotrans AG

Other oiling and greasing systems

spray.xact food is a high-performance, technically advanced spraying system for low-mist, precise and economically efficient application of media. The solution is an enhancement of the system based on the proven technotrans spraying technology originally used in punching and forming applications.

It has been specifically tailored to the requirements of food producers. Conventional compressed-air operated systems are often associated with the generation of aerosols which are inhaled by employees and accumulate as deposits in the production environment if extraction systems are not used. spray.xact food enables users to prevent these problems: The temperature-controlled valves ensure optimum viscosity of the applied medium by means of precise temperature control. In addition, the unit offers outstanding flexibility.

All the relevant parameter settings, from the temperature to the spraying quantity, can be adjusted to actual requirements by the user on each individual spray valve. Moreover, spray.xact food is also available as a mobile version.

spray.xact

|

Flexible airless spray lubrication without spray mist

technotrans AG

Other oiling and greasing systems

Flexible airless spray lubrication without spray mist

Precise, economical and reliable in production: spray.xact is the new generation of spray lubrication solutions. This highly flexible solution is ideal for the contact-free and precise application of oils and many other media. The spray jet is produced with a high-frequency valve with a 1-substance nozzle.

The advantage compared to conventional, compressed-air operated solutions: no unwanted mist and no need for an extraction system. These characteristics make spray.xact an economical and low-wear and low-maintenance solution which is suitable for use in a whole range of fields ? for example, for punching and forming applications, fine blanking and for rolling mills. Depending on the specific order, technotrans offers various different solutions: thanks to its flexible modular design, spray.xact b is ideal for retrofitting and re-equipping under limited spatial conditions.

The compact spray.xact c on the other hand is a spray unit in a nearly closed stainless steel housing which is particularly notable for its service-friendly features. The spray.xact spray units are supplied and controlled via the spray.xact fs.

ECOtec.chiller pure

|

The cost-optimised and highly compact standard system

technotrans AG

Central cooling systems

Modularity and flexibility taken to the next level: ECOtec.chiller is the new modular platform for bespoke, energy-efficient cooling solutions with a convincing power density for a wide range of industries. pure.line is the cost-optimised, compact variant of the chiller that can be configured in line with specific requirements by way of a user-friendly microprocessor-based control panel.

Even the standard version of the pure.line system is equipped with an easy-to-clean aluminium fabric air filter. A filter monitoring system indicates when the air filter needs to be cleaned. As a result, sensitive machine assemblies are effectively protected against soiling and the service life of the cooling medium is increased.

The areas requiring maintenance are all arranged at the front and a fill level indicator which can be checked from the outside ensures the easy handling, operation and maintenance of the unit. Additional advantages include the space-saving design in a modular housing and the small CO2 footprint.

ECOtec.chiller xtend

|

Thermal management solution with an outstanding energy efficiency and adaptability

technotrans SE

Central cooling systems

The xtend.line is the highly flexible variant of the new modular ECOtec.chiller. Its area of application includes all types of processes where the temperature and fluids play an important role ? regardless of the industry.

Thanks to numerous equipment options, the thermal management solution can be specifically adapted to a wide range of requirements, e.g. by way of additional cooling circuits, media or an outdoor option. However, the xtend.line does not only offer a high level of flexibility. Its energy efficiency and power density are also noteworthy.

The refrigeration consumption is up to 60% lower than with conventional solutions. Depending on the ambient temperature, the unit automatically adjusts the optimum operating point (SEPR value) of the complete system in terms of its energy efficiency. The result: cost savings and a reduced CO2 footprint. Another striking feature of the solution is its high level of operational reliability: Additional sensor systems in the refrigeration circuit as well as in the cooling medium circuit ensure continuous process monitoring.

central.cooling

|

Central cooling system

technotrans AG

Central cooling systems

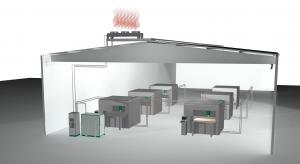

CENTRAL WATER COOLING - AN EFFECTIVE ALTERNATIVE

Stable humidity and temperature are a fundamental requirement for the production of high-quality products, especially when it comes to repeat jobs. Heat sources have a negative effect on the fragile balance between relative humidity and temperature. In order to counter this effect, water-cooled

peripheral units are widely used these days. Based on over 50 years of development and project experience, technotrans ensures the reliable supply of these units with cooling water. The productivity in the production area increases continuously.

Water cooling has been the standard method for motors in automotive engineering for a long time. However, water can also absorb the waste heat of the machine and withdraw it from the production area. Compared to air cooling, water cooling requires only small pipe cross-sections for a high level of

performance, which is due to the special physical characteristics of water.

The cooling of highly precise machines is indispensable these days owing to their power density. Studies show, for example, that the cooling of drive motors and cooling lubricants accounts for up to 50 % of the total power input. One major cause: every machine has its own cooling system, thereby representing an isolated supply point. Our solution: a central system combines these isolated supply points in a cluster and aligns the capacity reserves by way of a superordinate intelligent control system.

The selection of the cooling method should always be based on the requirements of the components in

need of cooling and on the climatic conditions on site. In general, free cooling is the method of choice. This method does not require any refrigeration unit and is characterised by particularly low operating costs and high reliability. Special applications requiring a constant water temperature make use of water chillers.

Water chillers with air-cooled condensers and a compact design for outdoor set-up are used for the cooling water supply with a feed flow temperature between 6 and 20 °C and outdoor temperatures up

to 45 °C. An integrated buffer tank and circulation pumps eliminate the need for a separate pump cabinet.

Available with cooling capacities from 25 kW up to 150 kW, with hermetically sealed scroll-type or semi-hermetical reciprocating piston compressors, various cooling agents, different sound pressure

levels and more options. A combination system with integrated free cooling enables annual energy cost savings between 40 and 60 %, depending on the desired cooling water temperature and

the climate on site. technotrans recooling systems are being used throughout the world. Benefit from our experience and the reliability of our proven technology.

technotrans will find the optimum solution for your specific application.

moldclean

|

Efficient cleaning of soiled circuits combined with improved heat transfer

technotrans solutions GmbH

Wastewater purification, plants and components

Limescale and corrosion are unwanted factors with a negative effect on the overall productivity: They considerably reduce the heat transfer, process reliability and product quality. Originally developed for reducing the cooling time of moulded plastic parts, the moldclean system is now also successfully used in heat exchanger systems.

The units offer a convincing level of effectiveness: Depending on the degree of soiling, the cleaning of injection moulds leads to a cooling time reduction of up to 40%, and in some cases even more. Customers benefit from a higher level of process reliability and reduced operating costs. The robust and user-friendly solution is available as a cost-efficient starter model with one tank and as an operating-cost-optimised variant with two tanks. Optional automatic ball valves can be used for switching between the cleaning cycles.

The moldclean unit can clean up to 8 temperature control circuits simultaneously.

toolsmart

|

Modular solution for the preparation and filtration of cooling lubricants

technotrans AG

Separators for coolants and lubricants, pumps, filters, centrifuges

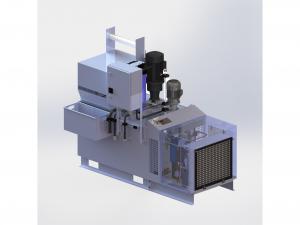

The toolsmart.line is a compact and modular solution for the preparation of cooling lubricants. It is characterised by its space-saving design and its ability to control numerous processes by way of a single control system. As a result, one single cooling system can supply several different manufacturing areas, for example. The result is a cost-efficient, resource-saving solution.

The heart of the toolsmart system is the filtration system. There are several different filtration modules for full flow, partial flow or bypass applications that can be combined as needed. The product portfolio ranges from the basic toolsmart.bt system up to the flexible toolsmart.xt unit with a tank capacity of up to 4,000 litres and a filtration rate of up to 750 l/min.

The toolsmart.cp is a combined spindle, control cabinet and cooling lubricant cooling system in a single unit. The modules are used in a central or distributed manner for a wide range of processes and can be complemented with additional components, including a temperature control unit or skimmer.