KAPP NILES

Products

precision for motion

KAPP GmbH & Co. KG

Profile grinding machines

ZX

The ZX series provides high-end productivity, even for bigger gears and larger modules. The requirements for outstanding flexibility can easily be met, too. The inherently rigid machine base enables easy installation without anchoring in the hall floor. The rotary table is generously dimensioned and can bear heavy loads. It is driven by an electrical high-accuracy direct drive, providing a high level of positioning accuracy even for the profile grinding process. The compact design enables all operations from the hall floor and allows for easy set-up for machining individual parts, low and medium serial production volumes. The changeover be-tween profile and generating grinding processes only lasts a few minutes. The tool spindle has a counter support for better rigidity and optimal surface finish. A wide range of dressing processes is available, e.g. double flank dressing with simultaneous tip dress-ing, single flank dressing and topological dressing.

KX 300 P

|

Gear grinding machine

KAPP GmbH & Co. KG

Gear grinding machines

Based on different tool and process technologies, user-specific, optimal production solutions can be configured.

The tool spindle with counterbearing can hold dressable and non-dressable grinding worms or profile grinding wheels. Due to the use of auxiliary spindles small grinding wheels up to a minimum diameter of 25 mm can be used. Machines can be loaded either manually or automatically. The use of an integrated ring loader allows short loading times for both bore and shaft parts.

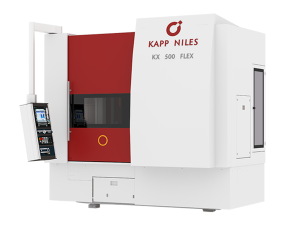

KX 500 FLEX

|

Gear grinding machine

KAPP GmbH & Co. KG

Gear grinding machines

The patented KX 500 FLEX is designed for the flexible use of a wide range of tooling and machining technologies. Thus, application-specific production solutions can be configured to perform diverse processing jobs and a wide range of batch sizes efficiently and economically. Dressable tools for versatile machining processes and non-dressable CBN tools can be used for highly productive manufacturing as well as grinding of gear geometry with interfering edges. The machine concept is based on a rotary indexing table which incorporates the tailstock and dresser offset against the workpiece spindle. The dressing unit can accommodate a single or twin spindle dresser.

Due to the use of auxiliary spindles small grinding wheels can be applied. Both involute internal gears and special profiles can be machined with the internal grinding device.