KAPP NILES

Products

precision for motion

Grinding machines

High speed grinding machines

HGS

|

High speed grinding machine

KAPP GmbH & Co. KG

High speed grinding machines

The high-speed grinding machine HGS is mainly used for grinding slots in pump rotors into the solid, through-hardened material. Slot widths of 0.5 to 2.0 mm can be produced with high efficiency due to package clamping and automatic unloading and loading. The in process measuring control ensures maintaining slot width tolerances.

The HGS uses non-dressable CBN profile grinding wheels only.

Grinding machines for other operations (grinding centres)

GAS

|

Grinding machine for other operation (grinding centre)

KAPP GmbH & Co. KG

Grinding machines for other operations (grinding centres)

Machines from the GAS model range are used for processing external threads and similar profiles. Typical components for these machines are external ball screws for automotive steering systems, as well as drive worms and small pumps and metering components. In line with the shaft-type geometry of the components, these machines are designed with a horizontal workpiece axis and have correspondingly long travelling paths. Parts are machined by discontinuous profile grinding only; the tool concept is adapted to the corresponding component requirements:

non-dressable CBN profile grinding wheels and dressable ceramic grinding wheels

For specific applications, various tools can also be combined.

GIS

|

Grinding machine for other operation (grinding centre)

KAPP GmbH & Co. KG

Grinding machines for other operations (grinding centres)

Machines of this type are used for the hard and soft finishing of internal threads in ball screw tracks or similar profiles. Typical applications besides vehicle steering are recirculating ball screws in the field of automotive.

Parts are machined by discontinuous profile grinding.

Non-dressable CBN profile grinding wheels are exclusively used, typically in a combination of roughing and finishing tools.

Profile grinding machines

KNG 3P ready

|

Profile grinding machine

KAPP GmbH & Co. KG

Profile grinding machines

The profile grinding machine KNG 3P ready offers an inexpensive entry into precision machining. It has been designed as a solution for flexible production of small and medium lot sizes. The machine is characterised by a grinding spindle with high drive power for components up to module 10 mm. The directly driven rotary table is generously dimensioned for a table load of up to 350 kg. The dresser sits stationary against the tool axis and even allows the use of small dressing wheels with a minimum diameter of 65 mm. The working area can be used without any restrictions at large helix angles. Thanks to the low height of the machine bed and the short distance to the machine elements all operations can be carried out without requiring means.

The innovative, operator-friendly user interface KN grind allows a machine-oriented and an intuitive input of all relevant project data.

KNG 12P master

|

Profile grinding machine

KAPP GmbH & Co. KG

Profile grinding machines

The machines in the master series are perfect for high-precision machining of external and internal gears as well as special profiles.

The machine concept stands for maximum workpiece quality. High thermal stability and rigidity are achieved through an optimised design and matching components. The inherently rigid machine base enables easy installation without anchoring in the hall floor.

The dressing and grinding spindles are equipped with state-of-the-art direct drives. The new functional and ergonomic machine design paired with an innovative user-friendly interface supports the user during set-up and optimisation of grinding projects. High-performance technology options and application-specific alignment and measuring devices mean that maximum quality can be achieved even with batch size 1.

ZE series

|

Profile grinding machine

KAPP GmbH & Co. KG

Profile grinding machines

The gear profile grinding machines in the ZE series are used for high-precision machining of external and internal gears. The machine concept stands for maximum quality, very straight forward handling and compact design. The machines are equipped with a dresser, counter support, integrated measuring device, balancing unit and comprehensive software for grinding and measuring of involute profiles, which enables machining of a wide range of applications.

Easy accessibility provided by doors that open wide, and oper-ation from the hall floor allow easy set-up for machining individual parts and small-scale serial production. The machines feature generously dimensioned rotary tables with electrical direct drive and deep rotary table bores. All machines of the ZE series can be equipped with internal grinding units.

ZP series

|

Profile grinding machine

KAPP GmbH & Co. KG

Profile grinding machines

The machine concept stands for maximum workpiece quality, flexibility and a long service life. The basic machines are equipped with a dresser, integrated measuring device, balancing unit and comprehensive software. The machines feature generously dimensioned rotary tables with electrical direct drive and large rotary table bores. Hydrostatic bearings and guides allow for pre-cise positioning, excellent load capacity and a virtually unlimited service life. Due to state-of-the-art drive and control technology, even the most challenging applications can still be machined using 5-axis interpolation.

All machines of the ZP series can be equipped with internal grinding attachments. Different spindle variants are available for grinding external gears.

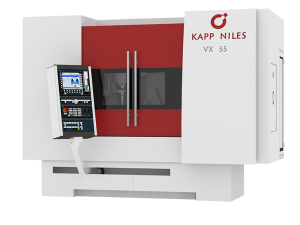

VX series

|

Profile grinding machine

KAPP GmbH & Co. KG

Profile grinding machines

The profile grinding machines of the VX series are extremely suitable for meeting the highest requirements concerning the final quality of the produced gears. Both dressable tools and non-dressable CBN tools may be used in the process. As the grinding adapter can be fitted with two exchangeable grinding spindles, the cutting passes can be realised with the sequential use of roughing and finishing tools in one workpiece set-up. As an alternative, multiple gears can be machined in one set-up.

VX machines configured for the use of dressable tools feature integrated dressing equipment producing any type of grinding wheel profile. The dressing and grinding programme is generated automatically based on the gear data. The combination of measuring system and profile dressing equipment also allows for automated machining according to the so-called GMG-strategy (grinding - measuring - grinding).

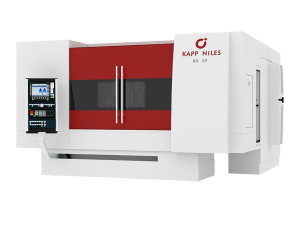

RX series

|

Rotor grinding machines

KAPP GmbH & Co. KG

Profile grinding machines

The machines of the RX series are used for pre-finish and finish grinding of pre-profiled steel and cast iron screw rotors.

Due to the innovative drive concept on the tool side, a maximum drive power of 46 kW is reached. Especially for roughing, this high performance results in extremely high stock removal rates and shortens machining times considerably. In combination with an optimally adapted tool technology, a highly productive and efficient working process will be guaranteed.

KX 300 P

|

Profile grinding machine

KAPP GmbH & Co. KG

Profile grinding machines

Based on different tool and process technologies, user-specific, optimal production solutions can be configured.

The tool spindle with counterbearing can hold dressable and non-dressable grinding worms or profile grinding wheels. Due to the use of auxiliary spindles small grinding wheels up to a minimum diameter of 25 mm can be used. Machines can be loaded either manually or automatically. The use of an integrated ring loader allows short loading times for both bore and shaft parts.

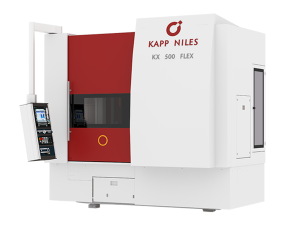

KX 500 FLEX

|

Profile grinding machine

KAPP GmbH & Co. KG

Profile grinding machines

The patented KX 500 FLEX is designed for the flexible use of a wide range of tooling and machining technologies. Thus, application-specific production solutions can be configured to perform diverse processing jobs and a wide range of batch sizes efficiently and economically. Dressable tools for versatile machining processes and non-dressable CBN tools can be used for highly productive manufacturing as well as grinding of gear geometry with interfering edges. The machine concept is based on a rotary indexing table which incorporates the tailstock and dresser offset against the workpiece spindle. The dressing unit can accommodate a single or twin spindle dresser.

Due to the use of auxiliary spindles small grinding wheels can be applied. Both involute internal gears and special profiles can be machined with the internal grinding device.

RX 120

|

Rotor grinding machine

KAPP GmbH & Co. KG

Profile grinding machines

The machines of the RX series are used for pre-finish and finish grinding of pre-profiled steel and cast iron screw rotors.

Due to the innovative drive concept on the tool side, a maximum drive power of 46 kW is reached. Especially for roughing, this high performance results in extremely high stock removal rates and shortens machining times considerably. In combination with an optimally adapted tool technology, a highly productive and efficient working process will be guaranteed.

With regard to pre-grinding, the patented rotor grinding machine RX 120 provides the option to use the advantages of continuous generating grinding instead of profile grinding in manufacturing rotor profiles. For the finishing operation, only profile grinding is used. By applying the generating grinding process as the pre-grinding process, a reduction of up to 40 % in grinding time can be realised compared to conventional machines and processes.