KAPP NILES

Products

precision for motion

Services

Second-hand machine tools

Service-Retrofit

|

Machine tool modernisation and overhauling

KAPP NILES

Machine tool modernisation and overhauling

KAPP NILES is taking account of production issues handling outdated machines by concentrating on modernisation work Retrofit. The advantages of an overhaul simply cannot be denied. Reinstalling cutting edge hard- and software enables restoring and even increasing precision as well as performance.

Up-to-date control components reduce maintenance costs by shortening the cycle period of the editing process.

A graphically refurbished software facilitates handling of the machine. Additionally, several features are offered that significantly speed up data entry and edit of the grinding programme.

Furthermore, retrofitting the new control and its installed interfaces prepares the machine for Industry 4.0 challenges. That way, today every retrofit machine is equipped with the latest remote maintenance technology.

Services for production

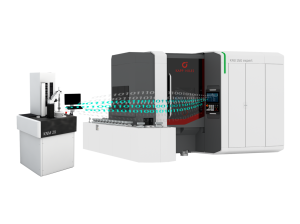

CLOSED LOOP

|

Digital Solutions - Perfect interaction for efficient processes

KAPP GmbH & Co. KG

Other services for production

What does Closed Loop by KAPP NILES include?

- Standardised transmission (GDE format) of correction values via network or USB

- Automatic or manual execution of corrections

- Correction values for profile angle deviation fh?, flank line angle deviation fh? and tooth width, sphere dimension, two-ball dimension Wk

What are the advantages of Closed Loop by KAPP NILES?

- Automatic correction of series parts during production according to defined rules, if necessary with spindle reference

- Reduction of the rejection rate

- Compatibility with machines from other manufacturers (both machining and measuring machine)

CONDITION MONITORING

|

Digital Solutions - Perfect interaction for efficient processes

KAPP GmbH & Co. KG

Other services for production

What does Condition Monitoring include?

- Monitoring of the linear and rotatory axes by reference runs

- Evaluation of the wear condition through indices from 0-100 and prognosis regarding durability

- Interface to other (digital) products in your production system, e.g. parts tracing

What are the advantages of Condition Monitoring?

- Reduction of unplanned machine downtime

- No unnecessary or premature replacement of components ? Reduction of inventory costs

- Maintenance of production quality through monitoring of quality-relevant components

DIGITAL SERVICE - REMOTE SERVICE

|

Digital Solutions - Perfect interaction for efficient processes

KAPP GmbH & Co. KG

Other services for production

What does Remote Service include? - Processing your service requests via a ticket system - Support through live video, voice over IP, chat and whiteboard functions - Documentation of your service activities for each system can be viewed in the system archive What are the advantages of Remote Service? - Faster and easier support and solution finding through targeted communication via a ticket system (no e-mail traffic) - Documentation, operating manuals and e-plans for each machine are digital and up-to-date available

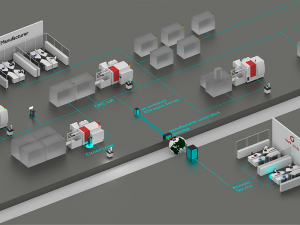

Digital solutions

|

Other services for production

KAPP GmbH & Co. KG

Other services for production

Digital solutions from KAPP NILES are displayed in the software platform KN assist. Our digital products aim to generate the greatest possible added value for you. Quality, availability, efficiency, resources, user-friendliness and service play a major role here. We focus on the core areas of connectivity, production, machine and support in order to master all current and future challenges together with you. The digital solutions thus stand for a perfect interaction of efficient processes around our machines.

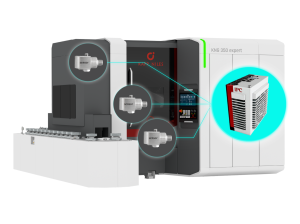

KN CONNECT

|

Digital Solutions - Perfect interaction for efficient processes

KAPP GmbH & Co. KG

Other services for production

What does KN connect include?

- Standardised connection to your network via a separate IPC

- IPC with firewall and OPC UA server

- Provision of data (umati data scope) via OPC UA

What are the advantages of KN connect?

- Standardised interface across machine manufacturers through OPC UA and umati ? Also for existing machines

- Machine becomes I4.0 ready ? Basis of digital solutions and requirement for further products

- Secured TÜV-certified interface

PART TRACING

|

Digital Solutions - Perfect interaction for efficient processes

KAPP GmbH & Co. KG

Other services for production

What does Part tracing include?

- Recording of defined data during the grinding process for each workpiece

- Creation of a data record for each workpiece with a defined identification (ID)

- Interface to your systems for transmitting the data records

What are the advantages of Part tracing?

- Complete traceability and documentation of all manufactured components

- Evaluation of data for process optimisation

- Reduction of the rejection rate through rapid identification of anomalies and potential sources of error together with connected analytical systems

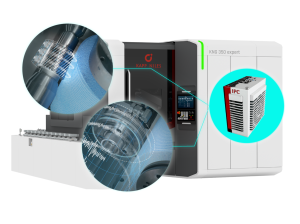

PROCESS MONITORING

|

Digital Solutions - Perfect interaction for efficient processes

KAPP GmbH & Co. KG

Other services for production

What does Process Monitoring include?

- Monitoring of the worm condition and analysis of ripples / orders

- Evaluation of the condition and indications based on the adjustable limits

- Interface to other products (such as parts tracing) and export function for analysis outside the machine

What are the advantages of Process Monitoring?

- Reduction of rejection rates through 100 % inspection of all components

- Early detection of defects ? Timely rejection of conspicuous components

- Process monitoring can be adapted to your individual requirements

TOOL MANAGEMENT

|

Digital Solutions - Perfect interaction for efficient processes

KAPP GmbH & Co. KG

Other services for production

What does Tool Management include?

- Guided change sequences (step by step)

- Avoidance of incorrect installation of a component with simultaneous flexibility

- Display of all relevant component information (ID, geometry data, process data, ...)

What are the advantages of Tool Management?

- Reduction of the risk of crashes due to the set-up of an incorrect component

- Reduction of preparation times for grinding project

- Support in planning and analysing the condition of a component