isel Germany AG

Products

Successful with cnc technology!

isel Germany GmbH

Five-axis milling machining centres

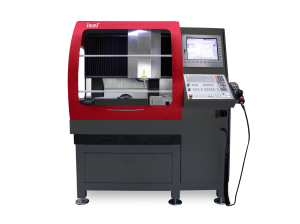

PREMIUM 1010 Micro

| mm | |

| kg | |

HIGH-PRECISION 5-AXIS MICRO-MACHINING WITH OPTIONAL AUTOMATION FOR ALMOST ALL MATERIALS!

The PREMIUM 1010 micro precision machine is predestined to produce high-precision small parts in single-item or series production. The 5-axis HSC milling system offers the additional option of connecting automation systems, such as handling systems or robots for unmanned production. Due to extended control and communication options, it is possible to integrate different automation units and to control them in the manufacturing process itself.

To ensure extreme rigidity and precision of the machine, the machine base structure was also realized in steel and ground hard stone. The ground natural granite was manufactured according to DIN 876 / grade 00 and used as the support material for all linear axes. This enables precise long-term stability and extensive temperature independence.

The highlights of the PREMIUM 1010 micro:

DRIVE

-Torque drives in A/B axes Heidenhain® measuring system

CONTROL

-Industry-standard, easy-to-use user interface

TOOL CHANGER

-32-fold tool changer

INTERFACE ADAPTATION

-Simple interface adaptations for further automation are guaranteed

WORKPIECE CLAMPING SYSTEM

-EROWA zero point clamping system

ACHSEN

-Linear motors in X-/ Y-/ Z-axes

-5-axis operation

Translated with DeepL

IMG 1510 X5

|

Five-axis milling machining centre

isel Germany GmbH

Five-axis milling machining centres

28xxxx SDU 8300

| Travel |

|

| 1000 mm | |

| 1000 mm | |

| 350 mm | |

| Machine control |

|

| Heidenhain | |

5 Axis Simultaneous Milling Machine for Wet and Dry Machining

The metal/granite sandwich construction für the moving axes such as gantry and crosshead can be driven by linear motors. It forms, in connection with high-precision linear guides, the

basis of the solid steel/granite machine construction. The advantages of natural stone granite in combination with high-strength light metal offer maximum rigidity and at the same time weight savings.

This is the only way to achieve the desired dynamics and high feed rates. The milling spindles used are high-frequency spindles with 1.5 KW, 2.0 KW or 4.0 KW and 40000 or 50000 rpm with HSK25 mounting.

The 10-station tool changer installed outside the working area automatically moves from the protective housing to the milling spindle. With the 4th/5th axis as a fork head version and the integrated high-precision gearbox drive modules, it is possible to reach almost all positions of a complex workpiece with the milling tool.

The machine is rounded off with new state-of-the-art CNC control functions and an easy-to-use user interface. These allow 5-axis simultaneous machining üvia RTCP – function (Rotation Tool Center Point). The control and operating components from Heidenhain include a touchscreen monitor and a convenient hand control. Different workholding systems can be applied to the universal granite table – via steel threaded bushings in a 150x150 mm grid, or a T-slot plate can be used.

Available in 5 different sizesü&aerospace;

iMG1010X5, iMG1510X5, iMG2010X5, iMG2015X5

Features:

OPTIONS:

FIELDS OF APPLICATION:

Für versatile application possibilities, we offer different workpiece clamping systems, which can be attached to the universal granite table via steel threaded bushings in a grid of 150x150 mm. Alternatively, a T-slot plate can also be used.

The machine is also equipped with state-of-the-art CNC control functions and features a userfriendly interface that enables 5-axis simultaneous machining via RTCP – function (Rotation Tool Center Point). Heidenhain's control and operating components include a touchscreen monitor and a convenient handheld control.

PLEASED MATERIALS:

- New steel/granite sandwich construction .

- 18-position tool change HSK-E25 expandable on request .

- HF spindle up to 4.0 kW and up to 45,000 rpm

- Optional encoder for thread cutting .

- Tool measurement/control

- 3D edge finder (radio)

- Minimum quantity lubrication

The metal/granite sandwich construction für the moving axes such as gantry and crosshead can be driven by linear motors. It forms, in connection with high-precision linear guides, the

basis of the solid steel/granite machine construction. The advantages of natural stone granite in combination with high-strength light metal offer maximum rigidity and at the same time weight savings.

This is the only way to achieve the desired dynamics and high feed rates. The milling spindles used are high-frequency spindles with 1.5 KW, 2.0 KW or 4.0 KW and 40000 or 50000 rpm with HSK25 mounting.

The 10-station tool changer installed outside the working area automatically moves from the protective housing to the milling spindle. With the 4th/5th axis as a fork head version and the integrated high-precision gearbox drive modules, it is possible to reach almost all positions of a complex workpiece with the milling tool.

The machine is rounded off with new state-of-the-art CNC control functions and an easy-to-use user interface. These allow 5-axis simultaneous machining üvia RTCP – function (Rotation Tool Center Point). The control and operating components from Heidenhain include a touchscreen monitor and a convenient hand control. Different workholding systems can be applied to the universal granite table – via steel threaded bushings in a 150x150 mm grid, or a T-slot plate can be used.

Available in 5 different sizesü&aerospace;

iMG1010X5, iMG1510X5, iMG2010X5, iMG2015X5

Features:

- Metal/granite sandwich construction .

- Twist-pivot cable head (4th And 5th axis)

- High dynamic linear motors in X and Y – axes .

- 18-cavity tool changer expandable to 36 tools .

- Heidenhain® TNC640 high-end control

- Tool measurement by toolsetter or laser

- 3D edge finder

- Handwheel

- Modern control panel

OPTIONS:

- Water cooling

- Heidenhain LMT TT160 / optional laser measurement

- 3D probe

- Handwheel

- Minimum quantity cooling

- Tool holders

FIELDS OF APPLICATION:

Für versatile application possibilities, we offer different workpiece clamping systems, which can be attached to the universal granite table via steel threaded bushings in a grid of 150x150 mm. Alternatively, a T-slot plate can also be used.

The machine is also equipped with state-of-the-art CNC control functions and features a userfriendly interface that enables 5-axis simultaneous machining via RTCP – function (Rotation Tool Center Point). Heidenhain's control and operating components include a touchscreen monitor and a convenient handheld control.

PLEASED MATERIALS:

- Precious metals for jewelry making .

- Stainless steel

- tempered steel

- Graphite

- ceramics

- Plastics such as PMMA/composite

- Copper

- Steel

- Titanium

- Special materials

- Medical technology

- Fine mechanics

- Micromachining

- Molding and prototyping

- Dental technology

- Jewelry industry

PREMIUM 5030 GRUNDMASCHINE MIT 3 ACHSEN

|

Five-axis milling machining centre

isel Germany GmbH

Five-axis milling machining centres

| mm | |

| mm | |

| kg | |

| mm | |

| kg |

GRANITE, STEEL AND LINEAR MOTORS FOR HIGHEST QUALITY OF WORK!

The PREMIUM 5030 is a 3-axis HSC milling system specially designed to meet the requirements of high-precision machining of small precision mechanical parts, micromachining and milling of graphite/copper electrodes. In order to meet this demand for precision, all essential points for process-reliable manufacturing have been integrated into the machine concept. The solid machine base, consisting of a natural hard stone granite gantry with decoupled Y-axis, guarantees high rigidity and long-term stability.

The individual granite elements are manufactured to DIN 876 / grade 00 accuracy. The pioneering linear motor technology and the incremental measuring method guarantee highest positioning accuracies at highly dynamic feed rates. The fastest control technologies (high-speed cutting) ensure harmonious path movements with maximum precision and simple user guidance; the control used here is the Heidenhain® TNC 640.

Features.

-Massive and stable machine structure made of ground granite components.

-small footprint due to compact design

-High-frequency spindle with up to 2 kW power and 50,000 rpm.

-HSK-E 25 change system

-HSC control technology with a block processing time in real time < 1 ms

-High path accuracy due to digital length measuring system

-high-load linear guides

-low-maintenance linear motors in X, Y, Z

-Heidenhain® TNC 640 control system

-Null point clamping system in the granite table for fast changeover from 3 to 5 axes

OPTIONS

-3D measuring probe for recording workpiece zero points or re-measuring workpieces

-Laser for non-contact tool control

-High-frequency spindles up to 100,000 rpm.

-4th/5th axis as rotary/swivel axis

-minimum quantity cooling lubrication system

-various controls from Heidenhain®

-manual control unit

-professional CAD/CAM solutions

Translated with DeepL

PREMIUM 5030 GRUNDMASCHINE MIT 5 ACHSEN

|

Five-axis milling machining centre

isel Germany AG

Five-axis milling machining centres

| mm | |

| mm | |

| mm | |

| mm | |

| kg | |

| m/min | |

| U/min |

GRANITE, STEEL AND LINEAR MOTORS FOR HIGHEST QUALITY MACHINING!

The PREMIUM 5030 CNC milling machine is a 3- to 5-axis HSC milling system specifically designed to meet the requirements of high-precision machining of small precision mechanical parts, micromachining and milling of graphite/copper electrodes. In order to meet this demand for precision, all essential points for process-reliable manufacturing have been integrated into the CNC milling machine concept.

The solid milling machine base, consisting of a natural hard stone granite gantry with decoupled Y-axis, guarantees high rigidity and long-term stability. The individual granite elements are manufactured to DIN876 / grade 00 accuracy. The pioneering linear motor technology and the incremental measuring method guarantee highest positioning accuracies at highly dynamic feed rates.

The fastest control technologies (high-speed cutting) ensure harmonious path movements with simultaneous precision. In addition, the easy-to-operate user guidance under Windows® with i-8000 control is convincing.

The highlights of the 5-axis PREMIUM 5030:

CONSTRUCTION

Solid and stable milling machine design made of ground granite components

Small footprint due to compact design

CONTROL

HSC control technology with a block processing time < 1 ms in real time

Control software under Windows® for i-8000

ZERO POINT CLAMPING SYSTEM

Zero point clamping system in the granite table for fast changeover from 3-axes to 5-axes

SPINDLE

High frequency spindle with 50,000 rpm / 2 kW

MOTOR

Low maintenance linear motors in X,Y,Z

ACCURACY

High path accuracy due to digital length measuring system

High load linear guides

Translated with DeepL