expect great measures

»flash« Tool-Monitoring

|

|

|

|

The »hobCheck« universal measuring machine from ZOLLER opens up unprecedented possibilities for the fully automatic and complete measurement of gear cutting tools, threading tools and cutting tools of all kinds. The swiveling »orthoScan« optics carrier guarantees distortion-free measurement of the tooth contour for tools with a pitch, allowing you to achieve highly precise measurement results.

|

|

|

|

|

|

|

|

With the ZOLLER »redomatic«, shrink-clamping tools are ready for use quickly. The »pilot 4.0« image processing software, the carrier unit, and continuous monitoring of job steps make quick and reliable work easier. The »redomatic« technology ensures the shortest process times. Even inexperienced operators can achieve these times after just a short initial training process. All components have a fixed place on the carrier unit. The »pilot 4.0« image processing software guides users through all job steps and controls many processes fully automatically. The software lists the required components for each job step, and shows where the components are located on the carrier unit on the screen. »redomatic« is the solution for adjusting, measuring, and length-specific shrinkclamping of tools.

|

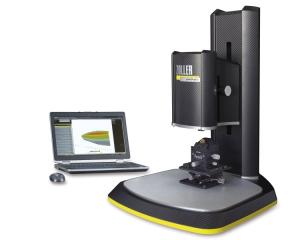

The »smartCheck 450/600/800« series from ZOLLER offers you comprehensive tool inspection. State-of-the-art technology paired with outstanding ease of use ensure efficient process sequences in your production. The wide variance of measuring ranges and the variable equipment make the »smartCheck« the perfect solution for your demanding range of tools. You can rely on precise measurement data that guarantees the quality of your products.

|

The best teammate you can have: the premium presetting and measuring machine »venturion«. The robust body consists of a light alloy specially developed for measuring machines. Made from exclusively high quality brand-name components with exceptional craftsmanship, nothing can compare to »venturion«. These precision machines can be used in any configuration and with any of the optional extensions – even the highest workload can be handled with ease. Its robust design makes »venturion« equally suited for a climate-controlled room or in the production hall right next to the CNC machine.

|

|

|

|

|

|

|

|

|

|

With the »3dCheck«, the perfect inspection machine for fast, process-oriented and fully automatic digitization of tool geometries, you can measure without contact and without damaging the tools.