Aluminum is one of the most important construction materials in many manufacturing sectors. At the same time, the material is very demanding when it comes to reliable welding results. A current customer project impressively demonstrates the difference that a clean, reproducible preparation process can make:

A manufacturer of extruded aluminum parts has used LASERVORM to add an upstream laser cleaning step to its existing laser welding process. This has reduced the scrap rate from 17 percent to well below 2 percent.

The challenge: Microstructure and surface problems with extruded aluminum and oxide layer

During extrusion, the aluminum is formed under enormous mechanical stress. This creates a fundamental problem:

Contamination from the extrusion process. During extrusion, various foreign substances get onto the component surface, including lubricant residues, metallic abrasion, and thermally altered residues. These contaminants are not only superficial; they are literally worked into the upper layer of the material by the high process pressures, making them difficult to remove.

In addition, aluminum oxidizes extremely quickly. A thin but very stable oxide layer forms on aluminum surfaces within a very short time. This aluminum oxide has ceramic properties and is considered a classic disruptive factor in laser welding. It hinders energy input, changes the behavior of the molten pool, and often leads to porosity.

The combination of oxides and impurities results in a complex surface structure that is difficult to remove and causes significant problems during laser welding. Seam defects, pores, and unstable molten pools were commonplace for the customer.

The result for our customer: a constant scrap rate of around 17 percent.

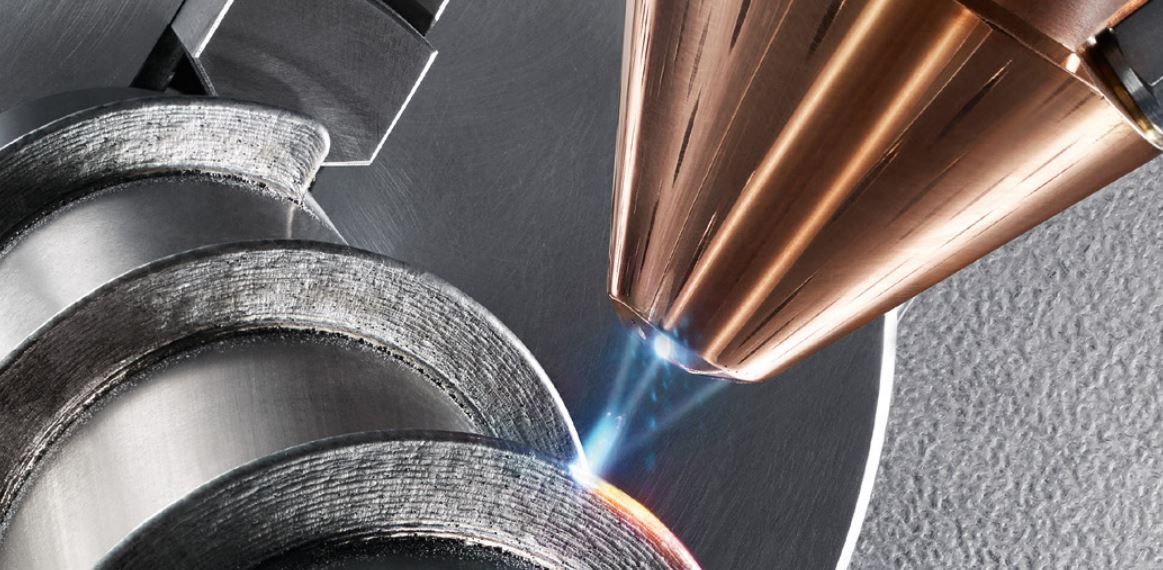

The solution: laser cleaning as an upstream process step

In order to prepare the surfaces reproducibly for the subsequent welding process, the process was expanded to include an upstream laser cleaning step. This involves the targeted removal of oxides, particles, and foreign matter: completely contact-free, without aggressive chemicals, and without additional mechanical stress. The parameters can be precisely adjusted to the material, resulting in a clean, bare surface.

This process has clear advantages, especially for aluminum:

- The oxide layer is reliably removed.

- Process-related contaminants disappear without leaving any residue.

- The surface becomes homogeneous and ideally prepared for a pore-free weld pool.

The result: Drastic improvement in process stability

Significant improvements were evident after only a short implementation phase. The decisive points: Reject rate reduced from 17% to less than 2%

- Pore-free weld seams in all relevant areas

- Increased process reliability, as the critical surface influence was eliminated

- Reduced rework and lower production costs

The decision to introduce the laser cleaning process upstream improved the entire welding process in the long term.

Conclusion

The project clearly shows that clean and reproducible surface preparation is crucial for successful welding of aluminum. Laser cleaning offers a highly precise and economical approach to reliably removing problem areas such as oxides and contaminants.

Anyone facing similar challenges in their production should consider laser cleaning as an integral part of the process chain—especially for demanding aluminum welding tasks. The laser cleaning process can be used as a standalone solution or integrated into a laser welding system such as the LV Midi or LV Midi X.

For more information: https://www.laservorm.com/en/home.html