Industrial manufacturing is faced with ever new and growing challenges. The shortage of skilled workers has long been omnipresent. In addition, there are shorter product life cycles and higher variant diversity with smaller batch sizes. At the same time, market dynamics and changing supply chains demand ever higher machine utilization rates, greater transparency over production and the ability of employees to perform their tasks in a targeted manner. In this complex environment, the concept of the digital twin is seen as a great beacon of hope. Reason enough to look beyond the boundaries of reality here and address the question: "So what is a digital twin?"

What is the Digital Twin?

The most important thing to say first: measured against human understanding, the concept of a digital twin is inadequate from a technical point of view. Admittedly, it is very much about the transformation of an actual or assumed reality with all its details and properties into digital space. However, such a digital replica would be completely incapable of action on its own and thus worthless.

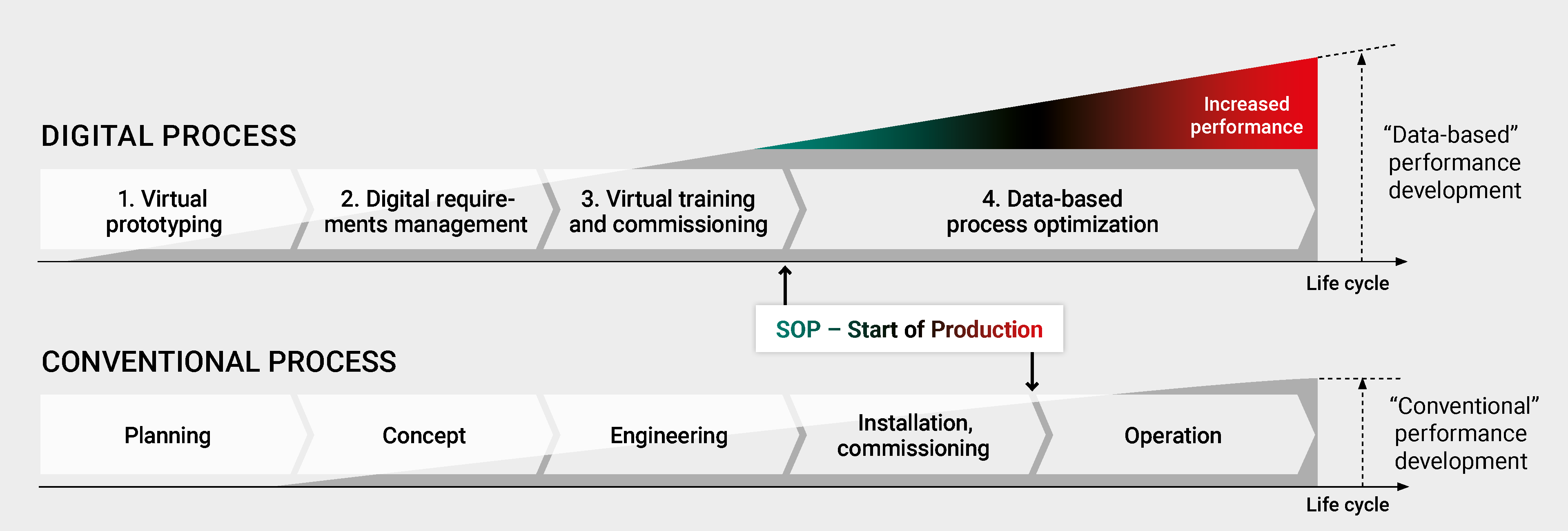

The Digital Twin only becomes really valuable through the digital model of the real object and its digital image. Digital models are therefore dynamic 3D representations of a real object that can be used for simulations and analyses. The associated digital images of the corresponding real components in turn represent the data captured or to be simulated from these models. Only through the inclusion of digital models and digital shadows of the actual component is the digital twin finally able to improve the products and processes concerned or prevent errors in a continuous control loop of simulation, analysis and optimization on the basis of the information generated.

- Increasing the number of spindle hours used productively

- Shifting non-production activities such as run-in processes and programming to the virtual world

- Preventing machine downtime due to collisions

- Reduction of component costs

- Reduction of cycle times through process optimization and transparency of cost drivers

- Prevention of rejects through prior simulation and simplified defect detection

- Empowerment of employees

- Reduced defect rate through early training and, if necessary, ongoing training

- Simplification of complicated work tasks by increasing transparency

Realistic test machining and trainings

In concrete terms, DMG MORI DIGITAL TWIN can therefore be used, among other things, to develop a planned machine completely in virtual space and to simulate, analyze and improve its capability with virtual controls, tools, clamping devices and workpieces until the result meets all expectations of the innovation. Every keystroke on the control, every tool change, every clamping situation, every axis movement, every spindle load: Everything can be digitally scrutinized and optimized with and on a Digital Twin. And that, mind you, even before the production of the "real" machine is tackled.

Furthermore, customers can then perform realistic test machining of their components while the machine is still being built. They can perfect CNC programs for their new machine and train their staff even before it is installed on their own store floor. And once installed, the machine can continuously communicate information to its Digital Twin about the status of the machine and jobs in progress. The data obtained in this way could be used to continuously improve processes and make well-founded operational and strategic decisions.

It almost seems as if the possibilities of virtuality only end at the limits of human imagination. Especially since digital twins are not loners, but can also interoperate with and among each other on the basis of a common syntax and semantics. What has been described above for the machine therefore also applies in a figurative sense to robotized manufacturing cells or to automated manufacturing systems with any number of machines, pallets and tools, as well as to autonomous transport vehicles and their routes within a store floor.

The only prerequisite is that every element of a system and every property of a service or process is also available with the associated data as a connectable digital twin. In any case, the more and the better the available information from the past and the more substantial the determined data from the present, the "smarter" the algorithms become and the more precise the analyses and the more accurate the answers. This is especially true when it comes to recognizing events even before they happen in reality.