I came here today to research which material is better for enclosure doors, Polycarbonate or Acrylic. The unanimous answer seems to be Polycarbonate so I'm moving forward with the doors for my new enclosure.

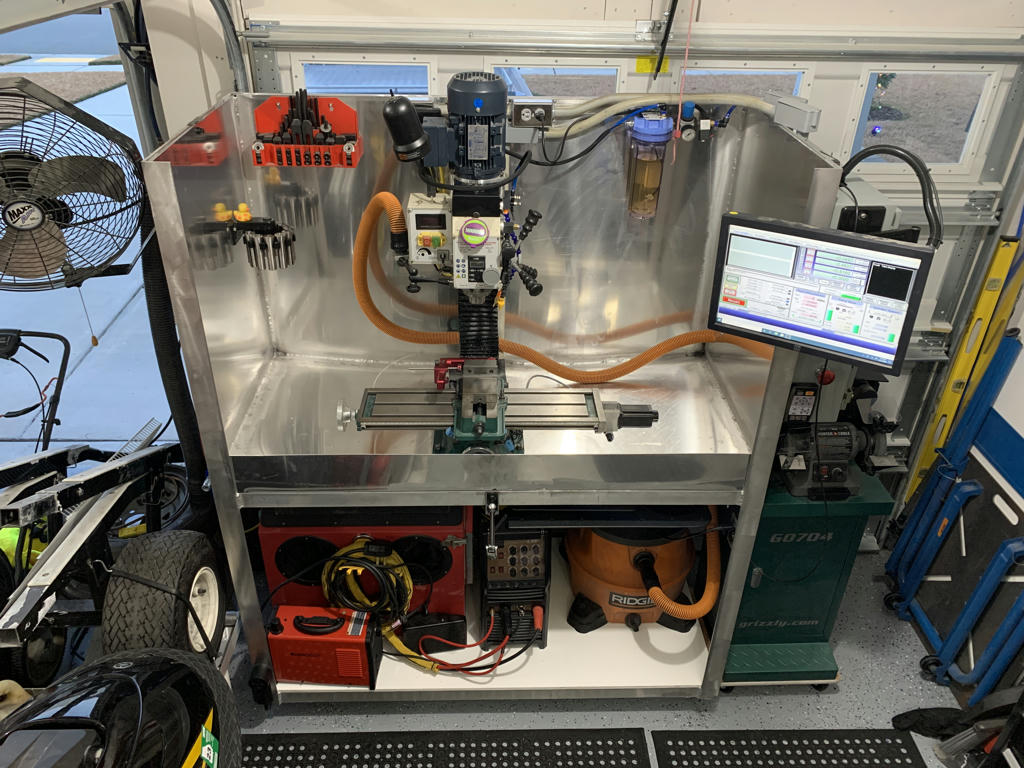

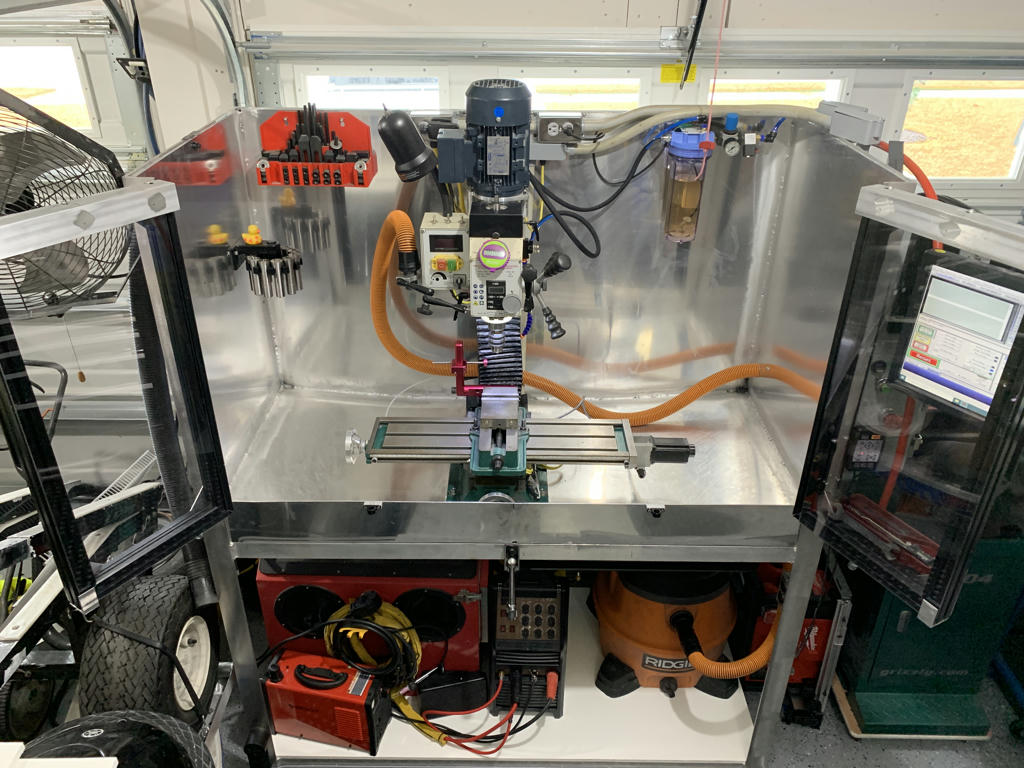

I've been using my converted mill for roughly 4 years in an enclosure built out of scrap 80/20 and 1/2" PVC sheet but I eventually want to run flood coolant so I had to come up with a sealed cabinet of some kind. The original design was my proof of concept and it's worked out extremely well so there didn't need to be too many changes made.

The material has been gathered for some time now but I've had some time at home recently so I finally took on this project.

Here's the old enclosure for comparison.

Plus it fits in better with my latest theme of converting everything in my garage to aluminum.

Results 1 to 13 of 13

-

12-14-2020, 09:57 PM #1

Member

Member

- Join Date

- Dec 2014

- Posts

- 8

OCD's Aluminum enclosure for converted G0704

-

12-14-2020, 10:45 PM #2

- Join Date

- Aug 2020

- Posts

- 21

Re: OCD's Aluminum enclosure for converted G0704

The attachments unfortunately don't work for me but i'm eager to see what you came up with. I've been thinking about building an 80/20 + polycarbonate enclosure with bi-fold doors for my PM25 for some time now but haven't pulled the trigger yet. It's tough to know what works best ergonomically without actually using the enclosure first.

-

12-15-2020, 11:45 AM #3

Member

Member

- Join Date

- Dec 2014

- Posts

- 8

Re: OCD's Aluminum enclosure for converted G0704

I'll work on the pics later. I uploaded direct to the site so I'm not sure why they aren't displaying.

I may have to host from my MediaFire Account.

I had the unit bench mounted for a couple years but once I started running cnc programs, I had to build an enclosure of some sort.

The 80/20 with PVC sheet was a cheap way to test out different configurations. It was actually sealed well enough that I could have run coolant.

-

12-15-2020, 10:50 PM #4

Member

Member

- Join Date

- Dec 2014

- Posts

- 8

-

12-16-2020, 01:25 AM #5

Member

Member

- Join Date

- Dec 2015

- Posts

- 923

Re: OCD's Aluminum enclosure for converted G0704

I used whichever was cheaper. I forget which one, I bought it at home depot. I find the windows only last a year or two until they are too beat up or brittle, so they have to be replaced anyways. I'm not sure how you are planning on supporting the windows, but frame them in reasonably well. It will help them last longer.

Great looking shop!

-

12-16-2020, 05:38 PM #6

Member

Member

- Join Date

- Dec 2014

- Posts

- 8

Re: OCD's Aluminum enclosure for converted G0704

I'm going to frame up the windows over the Christmas break so I'm looking over inventory to see what I can build with what I already have at hand and then shopping for the rest.

I'd love 6mm Polycarbonate with the UV and scratch resistant coating but that is more than I'd care to invest right now and way overkill for how I've used the mill historically.

I'm a hobby builder so I'm not doing any heavy production or aggressive work. More than anything, I just need something clear that will keep the chips in.

I've budgeted enough for 3/16" Polycarbonate.

-

12-17-2020, 09:22 AM #7

Member

Member

- Join Date

- Dec 2003

- Posts

- 1236

Re: OCD's Aluminum enclosure for converted G0704

If your work area sees big temperature variations you need to be aware that polycarbonate moves quite a bit.If you through bolt with tight fitting countersunk bolts it can lead to cracking around the bolts.Either trap the edges with a clamping strip or use bolts and washers in holes with a bit of clearance.

-

12-17-2020, 01:45 PM #8

Member

Member

- Join Date

- Dec 2014

- Posts

- 8

Re: OCD's Aluminum enclosure for converted G0704

Excellent advice right there. I had planned to drill and countersink but I can adapt a clamp strip easy enough.

The only sheet of material I can find local is almost double what I need so I’ll have a complete spare set of panels.

-

12-17-2020, 05:27 PM #9

Member

Member

- Join Date

- Dec 2015

- Posts

- 923

Re: OCD's Aluminum enclosure for converted G0704

I generally just glue mine in with clear silicone. I get the best life out of them that way. It does make removal problematic (clean up with a flap wheel helps) and you have to make damn sure that everything is clean for it to work, but I find it's easy to do and the panels don't split because there aren't any holes at all.

-

12-17-2020, 06:17 PM #10

Member

Member

- Join Date

- Dec 2014

- Posts

- 8

Re: OCD's Aluminum enclosure for converted G0704

I still like the idea of using the 1” 1010 extrusion with a rubber seal and may go back to that idea now. It solves more issues than it creates so it’s a win on many levels.

-

01-07-2021, 08:24 PM #11

Member

Member

- Join Date

- Dec 2014

- Posts

- 8

Re: OCD's Aluminum enclosure for converted G0704

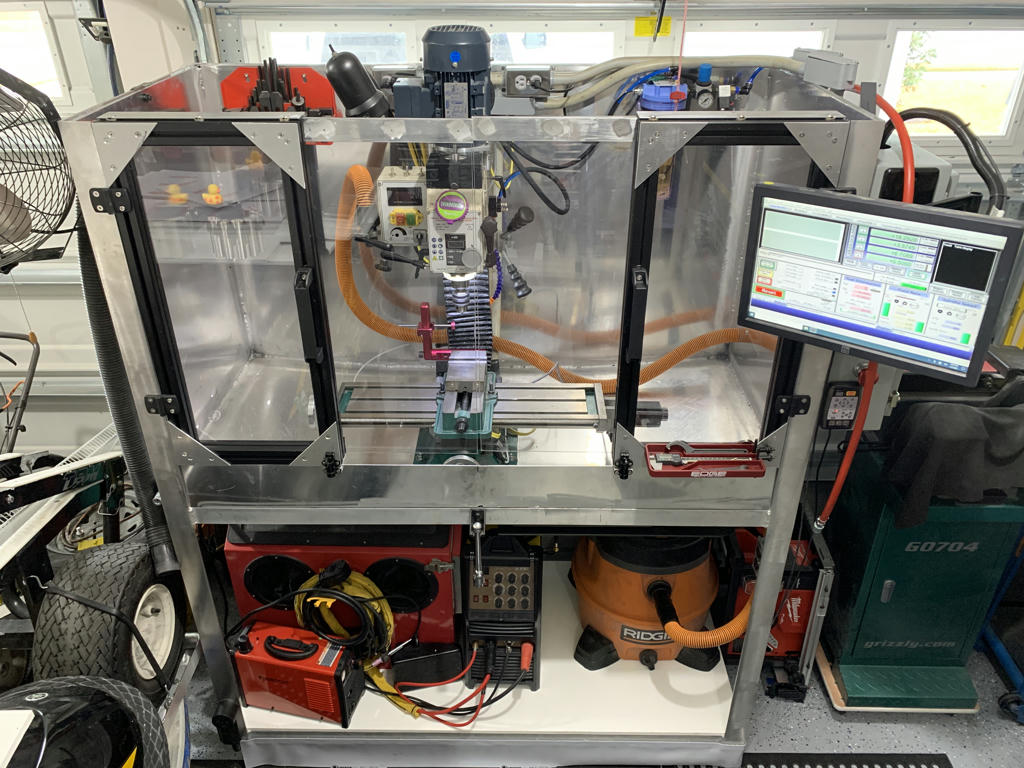

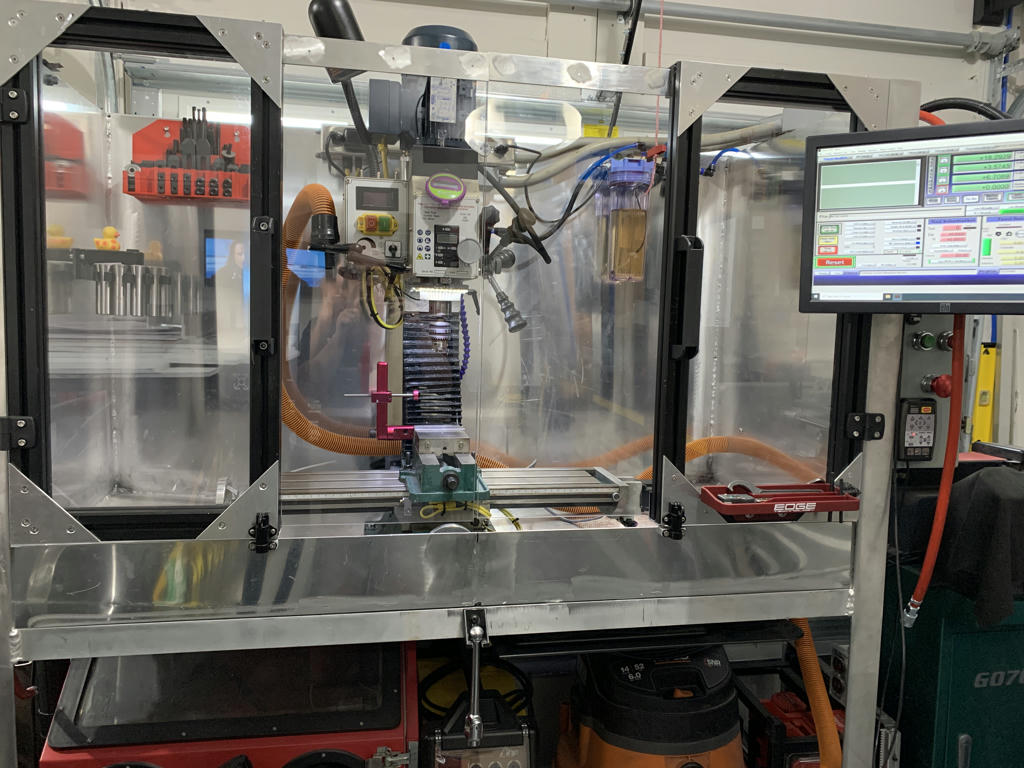

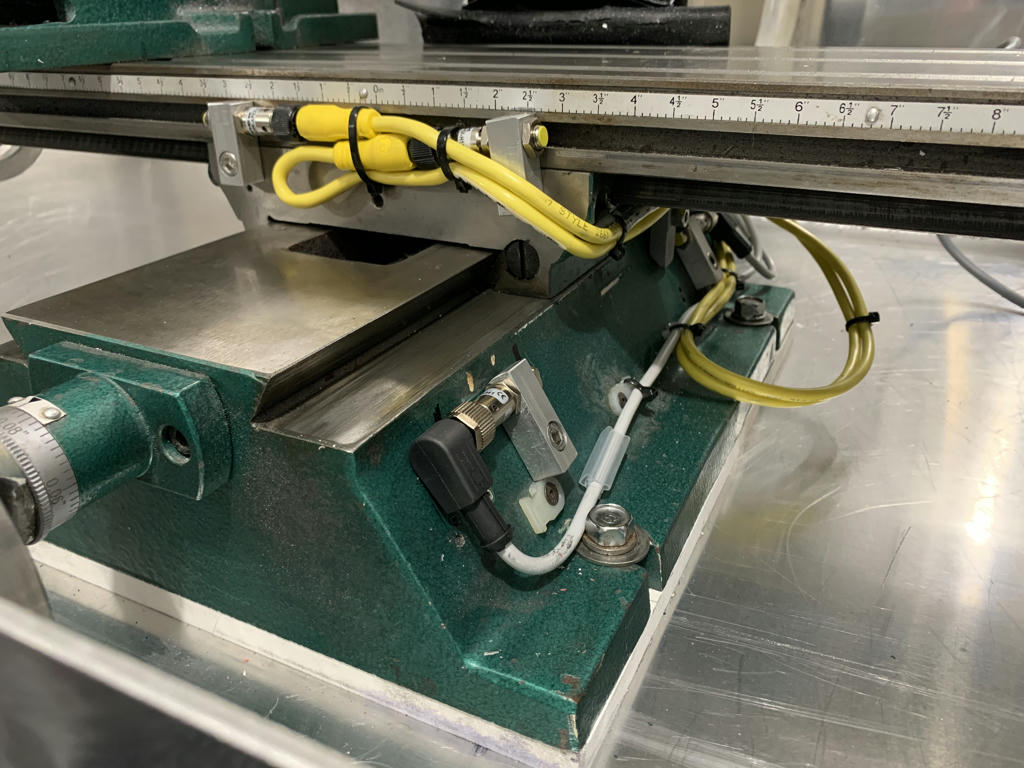

I made some progress on the doors. They are not perfect but a very good start.

I didn't end up with enough clearance from my vise to the door so I now have to look at reducing the space taken up by my Y axis motor so I can move the entire mill back about 5 inches in the enclosure.

My Y axis is out the rear of the machine which is not very common.

I also got my limit switches upgraded to proper inductive prox's with quick connect cabling.

-

01-09-2021, 07:59 AM #12

Member

Member

- Join Date

- Oct 2013

- Posts

- 543

Re: OCD's Aluminum enclosure for converted G0704

The enclosure looks beautiful, but let me say this...I certainly wouldn't have anything inside that enclosure that I didn't want coated with chips and coolant and smegma...that means all the stuff you have inside the enclosure...collets, clamps and oilers, not to mention the electrical outlet. If you need a enclosure, it means the crap & coolant is going to fly, and that means nothing is going to stay healthy for long inside the cage!

Stuart"THE GRIZZ" photo album - https://goo.gl/photos/yLLp61jooprtYzFK7

Youtube - https://www.youtube.com/channel/UCT2lq9obzEnlEu-M56ZzT_A

-

01-09-2021, 03:17 PM #13

Member

Member

- Join Date

- Dec 2014

- Posts

- 8

Re: OCD's Aluminum enclosure for converted G0704

I understand your point but this machine is almost 5 years old at this point and still looks pristine so you can get an idea of how it's used.

It's not a production piece and won't see the abuse you might think. In fact, 90% of the CNC work I do is actually with acetal or plastics.

I have worked in maintenance for over 30 years so I know how nasty flood coolant can be. The smell alone is what will likely keep it out of my garage.

Reply With Quote

Reply With Quote