Wow!!!! It’s been like a ghost town on these forums. Hope everyone is doing wellBefore I get into the main topic of this post, I wanted to give you folks an update on my mill. Well, it has been running…somewhat. There is that occasional spindle halt when peck drilling a .201 hole, .425 deep. I also had some issues with the original proximity switches. Lastly, I think my z axis stepper is starting to act up

Besides that, I’m making chips…lol.

Anyway, I was kind of obsessed with a couple small leaks that I had. One was at the corners of the front door and another at the right rear..facing the mill. They weren’t big leaks, just a dribble. By the end of the day of machining, there would be a small puddle at the two corners of the base. The other issue I had was overspray when I used flood coolant.

Almost forgot, I also had a problem with my door hinges…actually the acrylic cracking. So before I get into the leaking stuff, here is how I handled the door issue. ….I made up some sandwiches

I used the existing holes and a liberal amount of super glue between the aluminum and acrylic.

Now for the leaks….. The door leak was annoying. I installed a bottom drip cap, which worked fine except for the corners of the door. After looking at how Mikini designed their sealing system, I saw some faults. First of all, when the door was fully closed, it would still overhang the bottom sill. This told me that the rubber was a bit too thick.

So I decided to do the extreme, remove all the rubber. This caused the door to go in further and eliminated the overhang problem. But, when I removed the bottom rubber seal, I saw that the bottom seal sat in a channel…which in my mind collected coolant and didn’t drain properly. I removed the part of the cabinet where the channel was spot welded onto and cut the channel off. After I cut it off, I smooth the spot welds down with a grinder. I then attached a length of 1” aluminum angle to the area where the channel was attached to. This provided a smooth surface for the seal on the bottom of the drip edge. And because there is a bit of an angle on the cabinet in this area, it provided some help with drainage. Here are some pictures of the aftermath …..

I also put a small bead of silicone around the cabinet section and on the length of the aluminum angle.

Here’s my cheap drip cap….

It’s been a few weeks of milling using flood coolant and the small puddles have disappeared. I think I will be installing small rubber buttons that are used in steel buck door frames, to give the acrylic a cushion when I forget to close the door gently.

My overspray problem was nothing serious; I just didn’t want any coolant getting to my keyboard and onto my computer. Both of which sit on top of the cabinet and do get the occasional splash. So I installed a shower curtain….actually two shower curtains.

I bought the curtains for cheap on Ebay. I liked that they are clear. The pvc is just 1” electrical conduit and I attached them to the cabinet with some post I made up and bolted into place.

I cut the curtains short on the sides (the front is open), but made the rear longer. The back end of the curtains is cut below another channel in the rear of the cabinet. This was the cause of my rear leak. Since I don’t move the curtain, I attached some small earth magnets, which I bought at Harbor Freight, around the bottom edges of the curtain.

Now my keyboard and computer stay nice and dry, as well as the other side where I keep my Allen wrenches and such

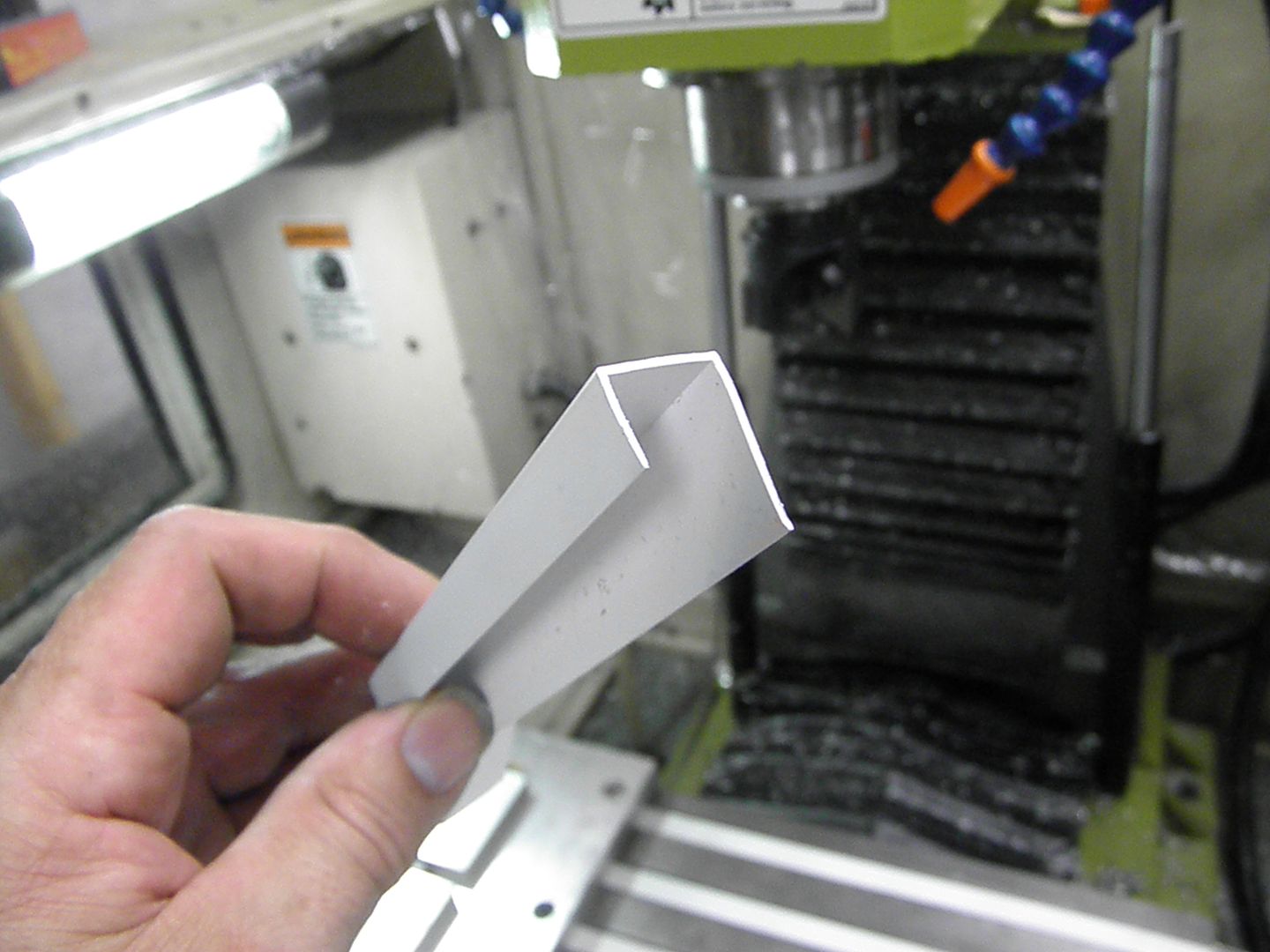

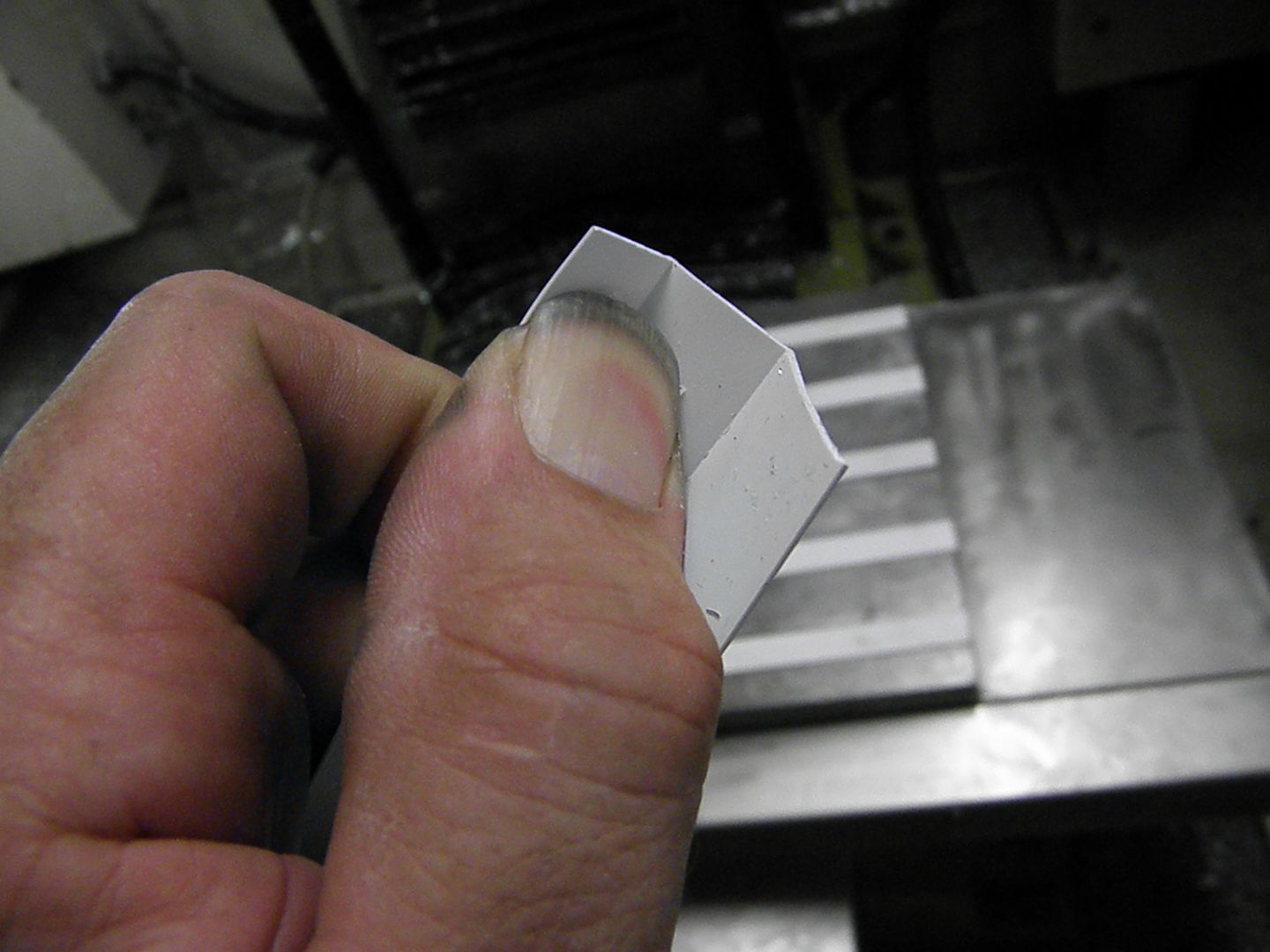

You may have also noticed my white slot covers. I saw this on another forum and I wish I could remember where, to give credit to. These are sheetrock end caps, I bought them at Home depot.

Cut to size and spread them out a bit….

And install….

I’m surprised how well they stay in place.

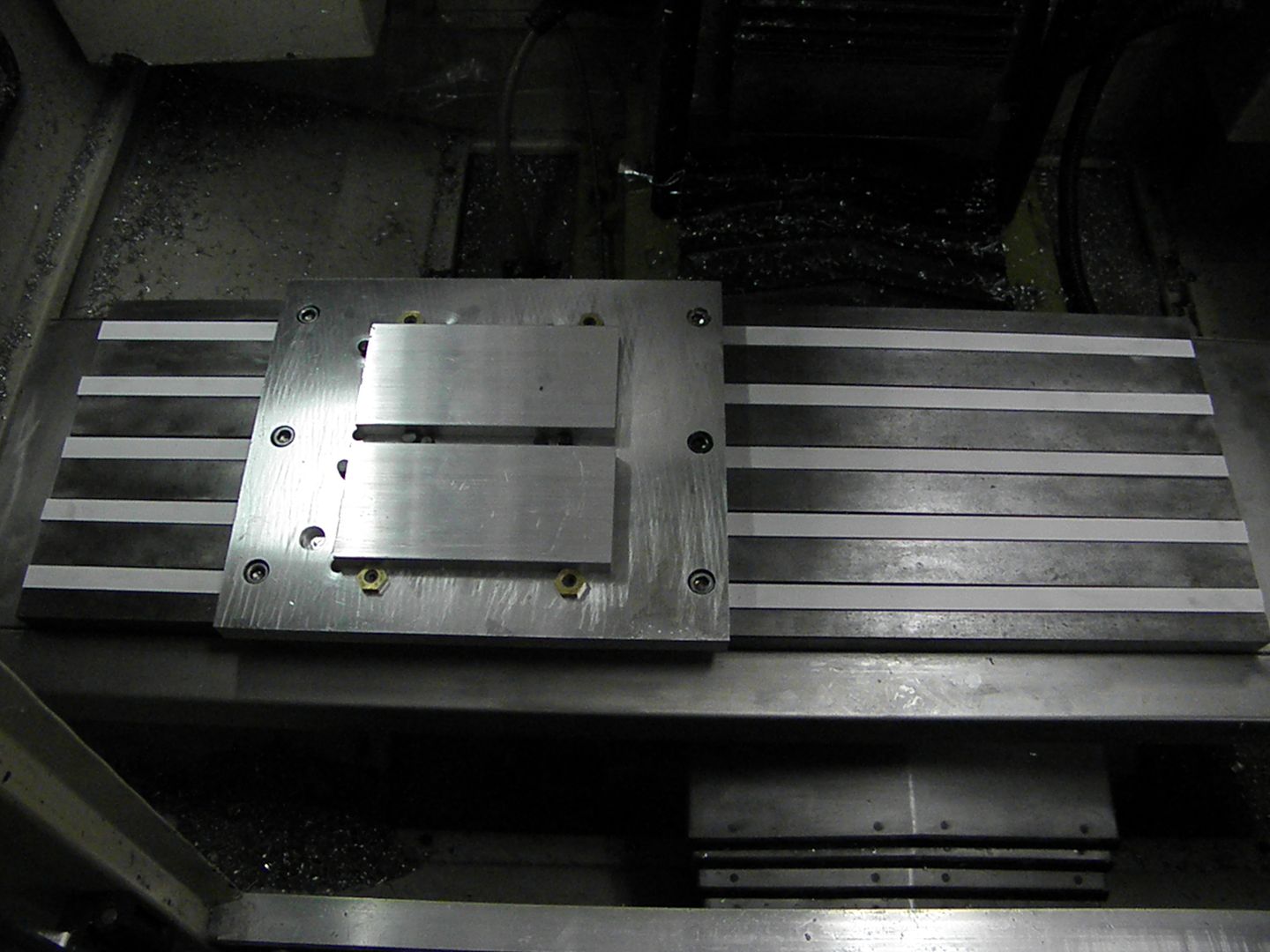

That’s it for now, but, here are some pics of things to come……

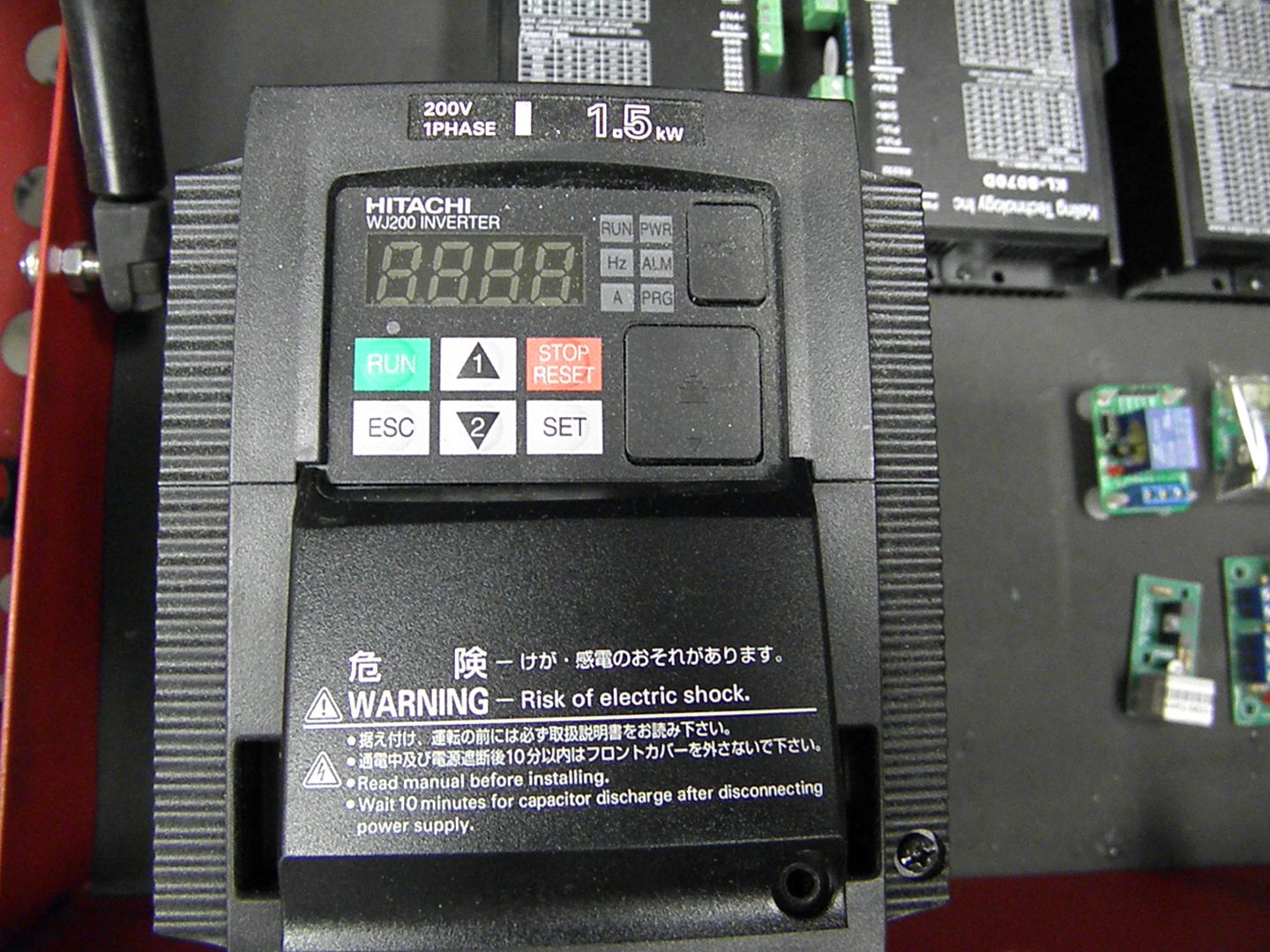

Hmmmmm, two pole (3600rpm) or 4 pole (1800rpm)…

Sensorless Vector drive….

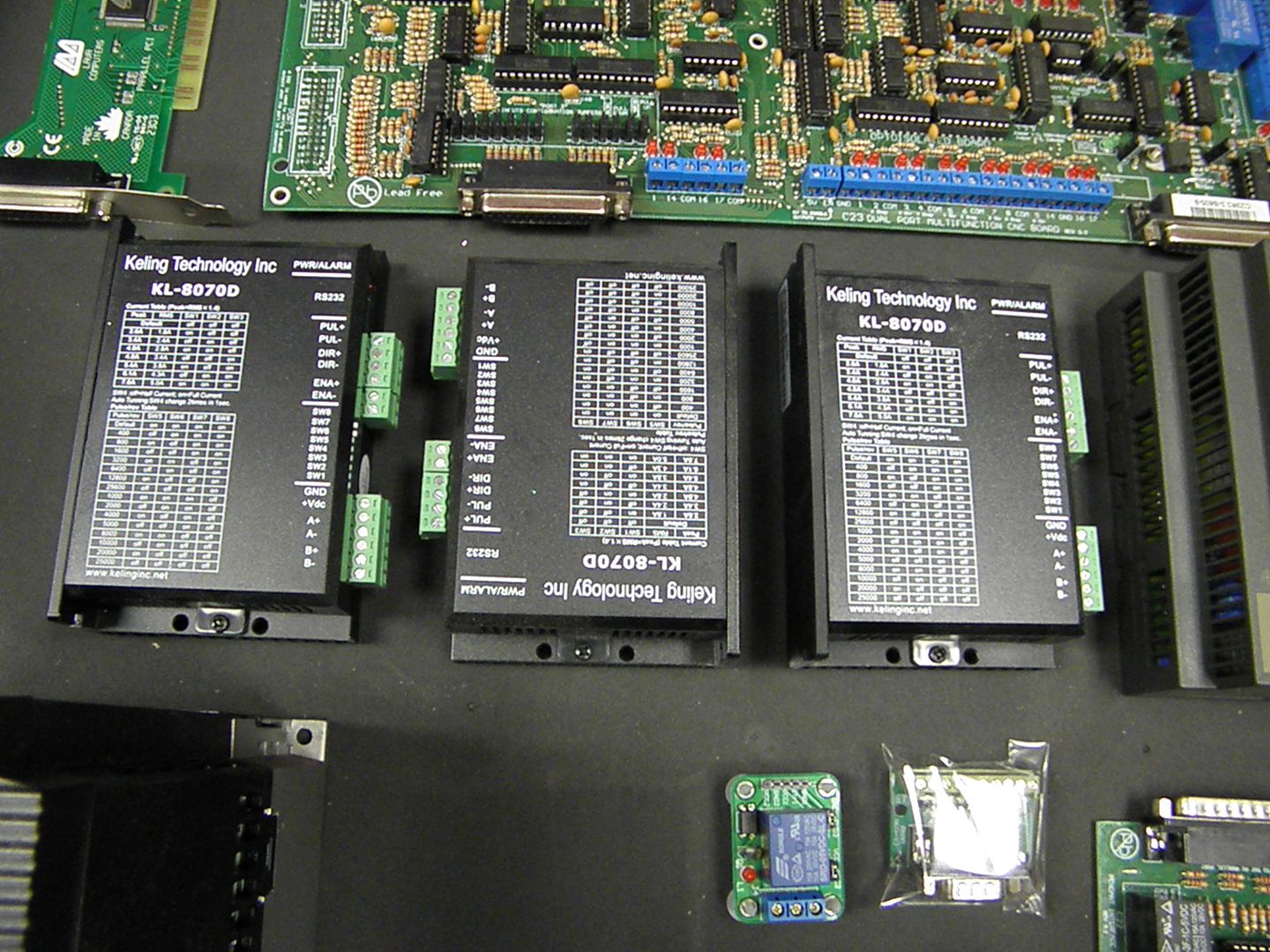

Some digital drives…

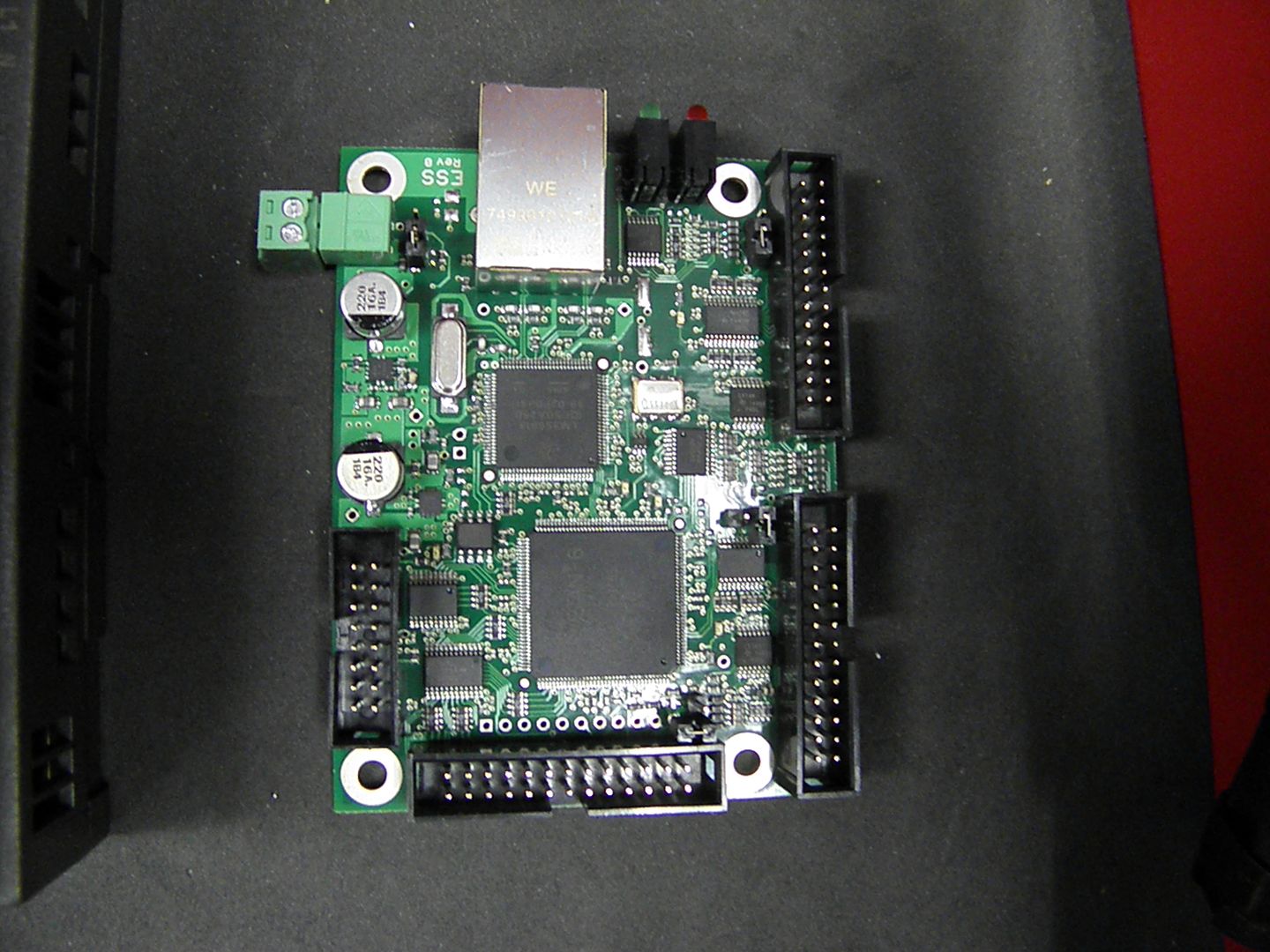

ESS Smooth stepper…

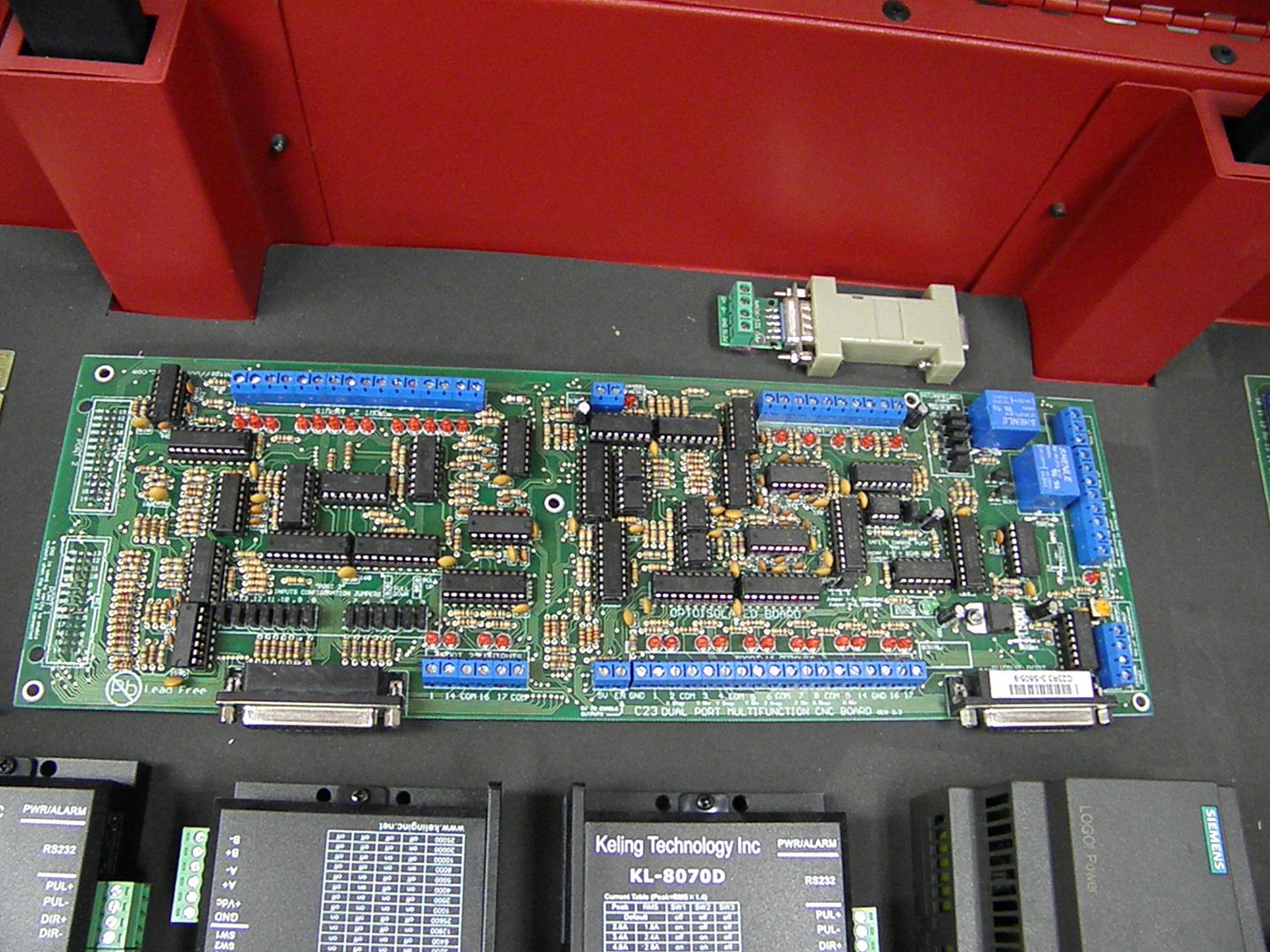

A big breakout board

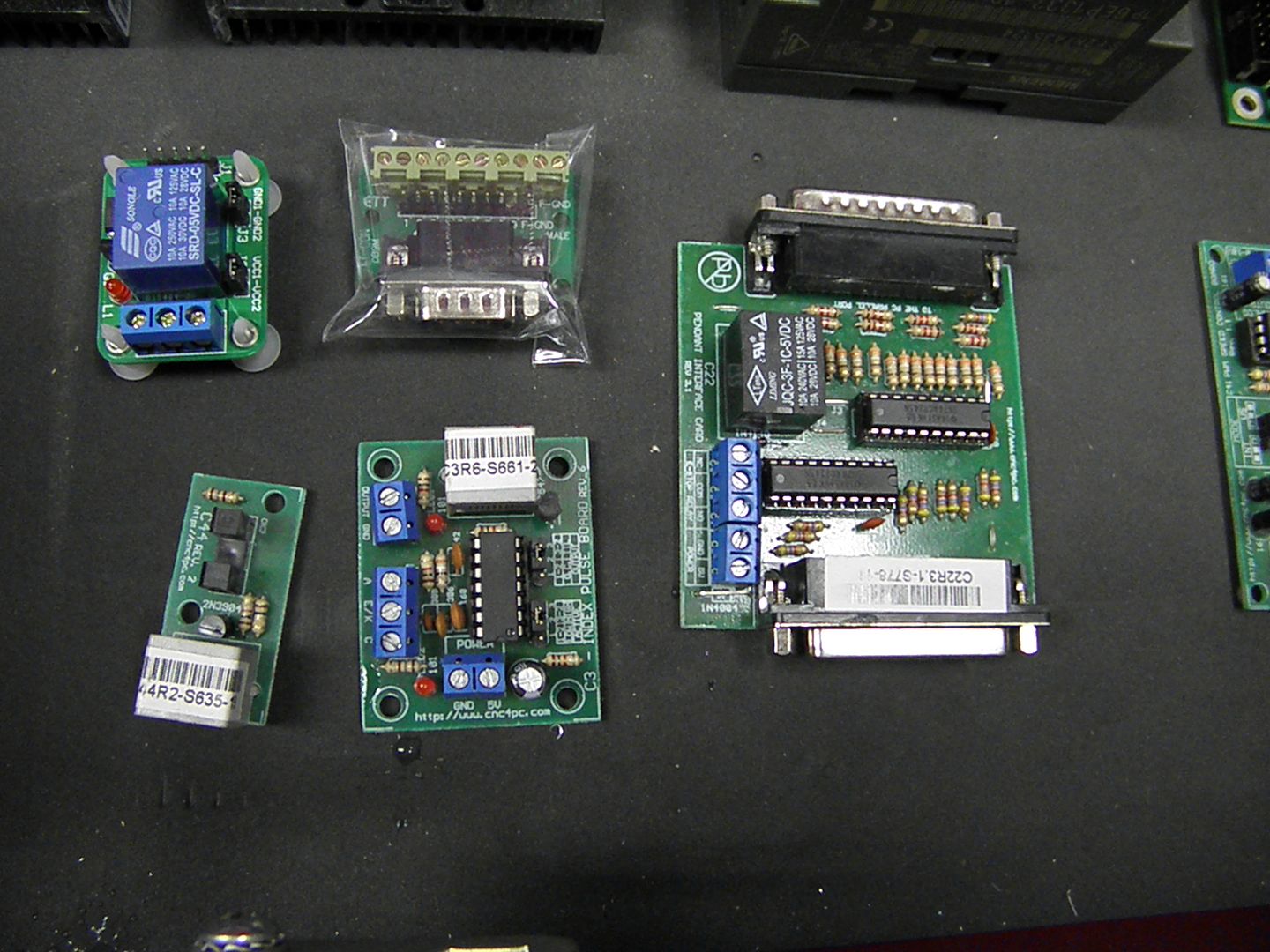

Bunch of other goodies…

Stay tuned….

Results 1 to 2 of 2

-

06-21-2012, 02:03 PM #1

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 367

Some cheap Coolant leak fixes and other stuff

pete

-

06-24-2012, 06:16 AM #2

Registered

Registered

- Join Date

- Dec 2008

- Posts

- 263

Nice Pete! That pile of parts is looking good.

Similar Threads

-

Puma 600/700 coolant leak from turret

By jani in forum Daewoo/DoosanReplies: 6Last Post: 02-20-2010, 02:03 PM -

Quick and Dirty X3 Coolant enclosure..cheap too!

By KOS in forum Benchtop MachinesReplies: 29Last Post: 12-02-2007, 07:27 PM -

Brand new VF-2 and I have a coolant leak

By akedward in forum Haas MillsReplies: 13Last Post: 11-19-2007, 06:28 PM -

Small Cheap flood Coolant system

By dneisler in forum Benchtop MachinesReplies: 10Last Post: 05-11-2007, 03:48 PM -

Cheap coolant system

By georgebarr in forum Uncategorised MetalWorking MachinesReplies: 8Last Post: 04-07-2004, 08:03 PM

Reply With Quote

Reply With Quote