Hello Folks, I have another thread where I redid an Emco 120P. i mentioned in that thread that I acquired an Emco 220. I finally had a chance to work on the 220 this week.

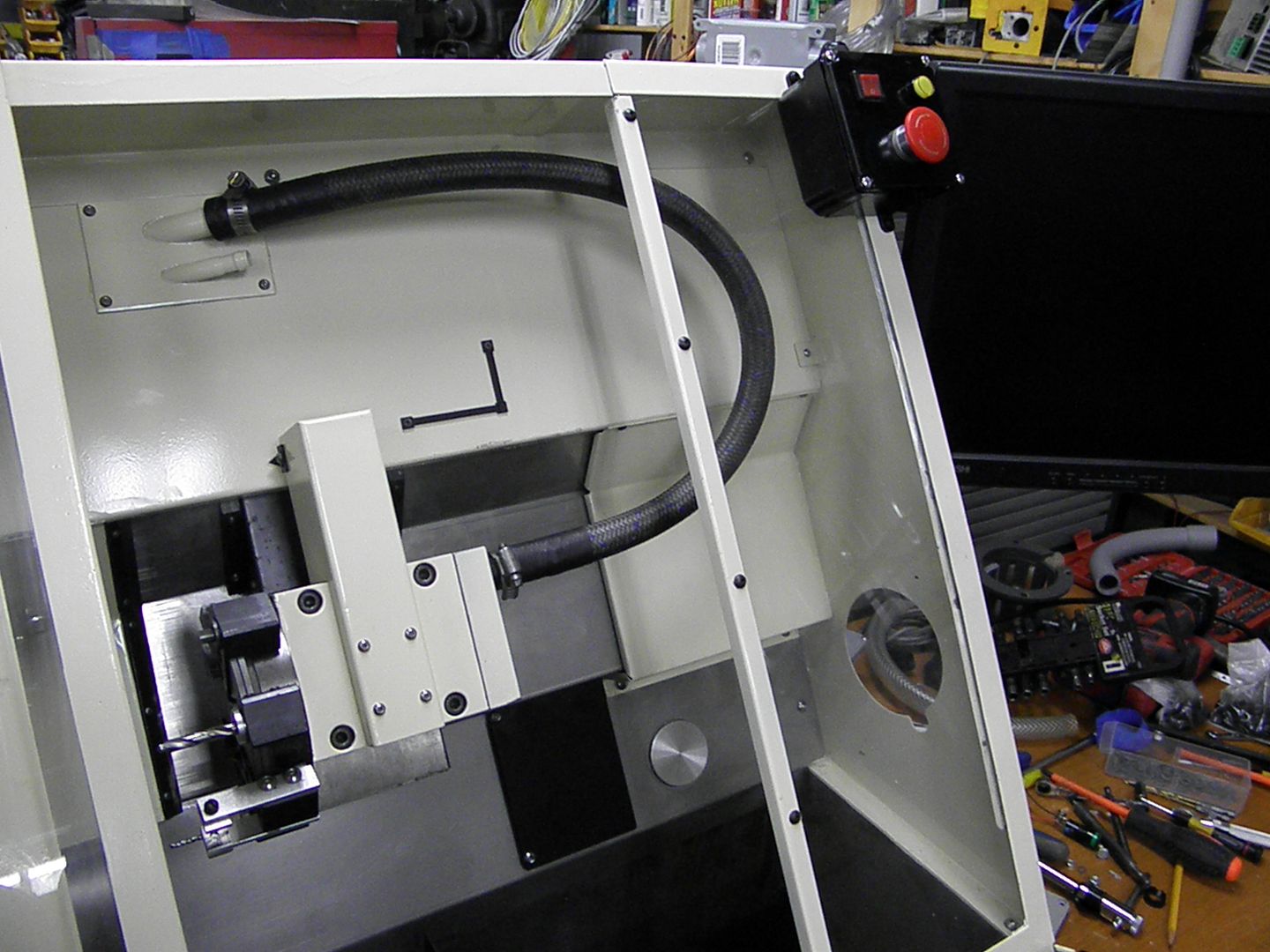

My plans are to basically mimic what was done to the 120P, remove all the old electronics and install new and easier to acquire stuffThe lathe will be under Mach3 control. I thought of using Linux, but, I don't want to go through a bunch of hoops to be able to use the rear tool turret. I also want to be able to use one of the newer motherboards I have laying around, which doesn't have a printer port.

Some of the new electronics that will be installed....PMDX126 bob...Pmdx107 speed control..Ethernet smoothstepper.. Hitachi WJ200 VFD driving a 2hp AC motor... Keling's digital drives (KL-8070D)..640 oz-in stepper motors.

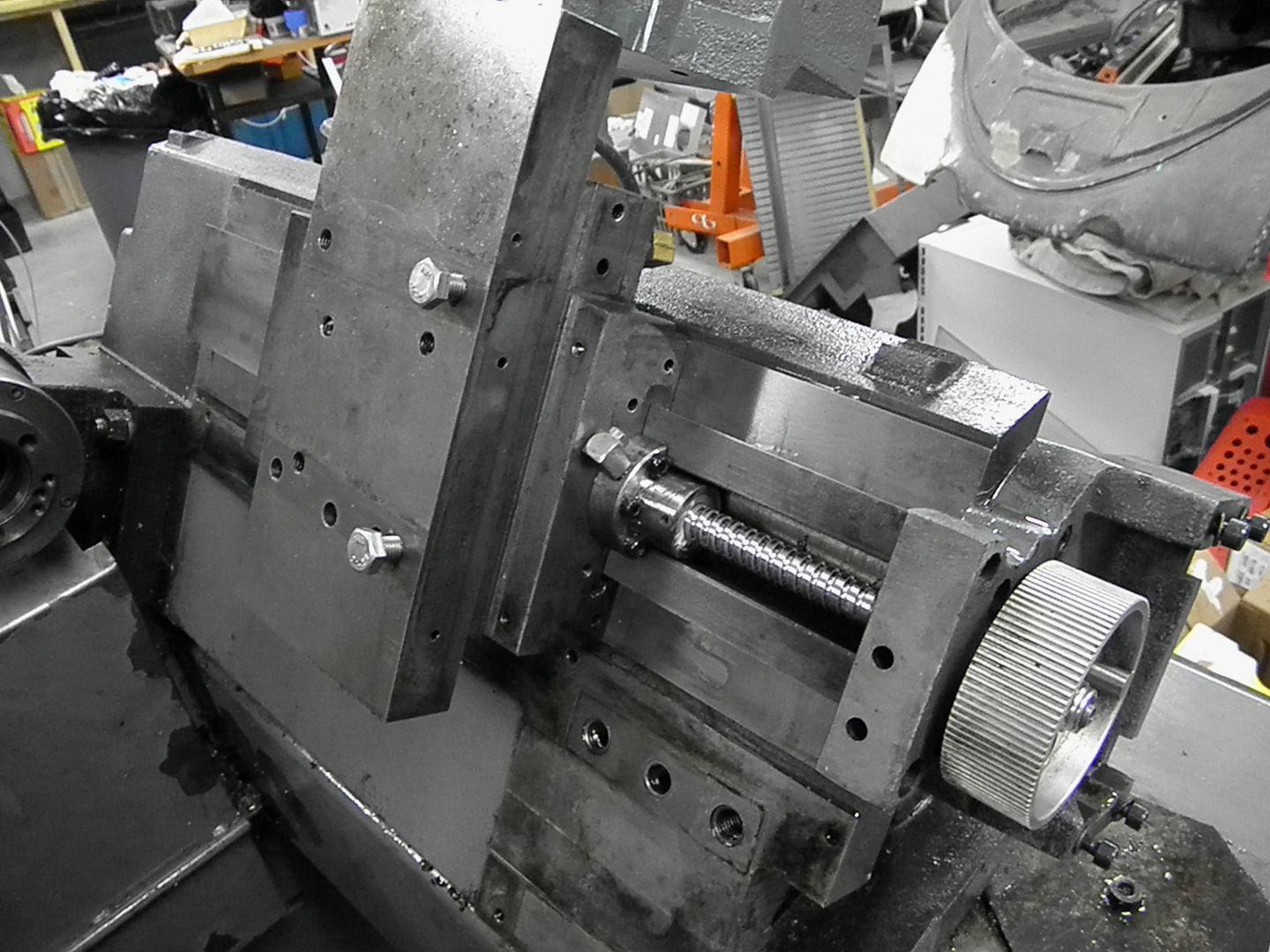

Anyway, I took apart and cleaned both slides. I removed both ball screws and soaked them over night in carb clearner, then into an ultrasonic cleaner. Afterwards a new filling of grease. I also replaced the bearings at the end of the screw..by the pulley. These are 608Z bearings. I bought a pack of 10 bearings from a skateboard dealer on ebay for about $8.00 and they were ABEC-7 bearings

Here's a pic of the slides re-installed.

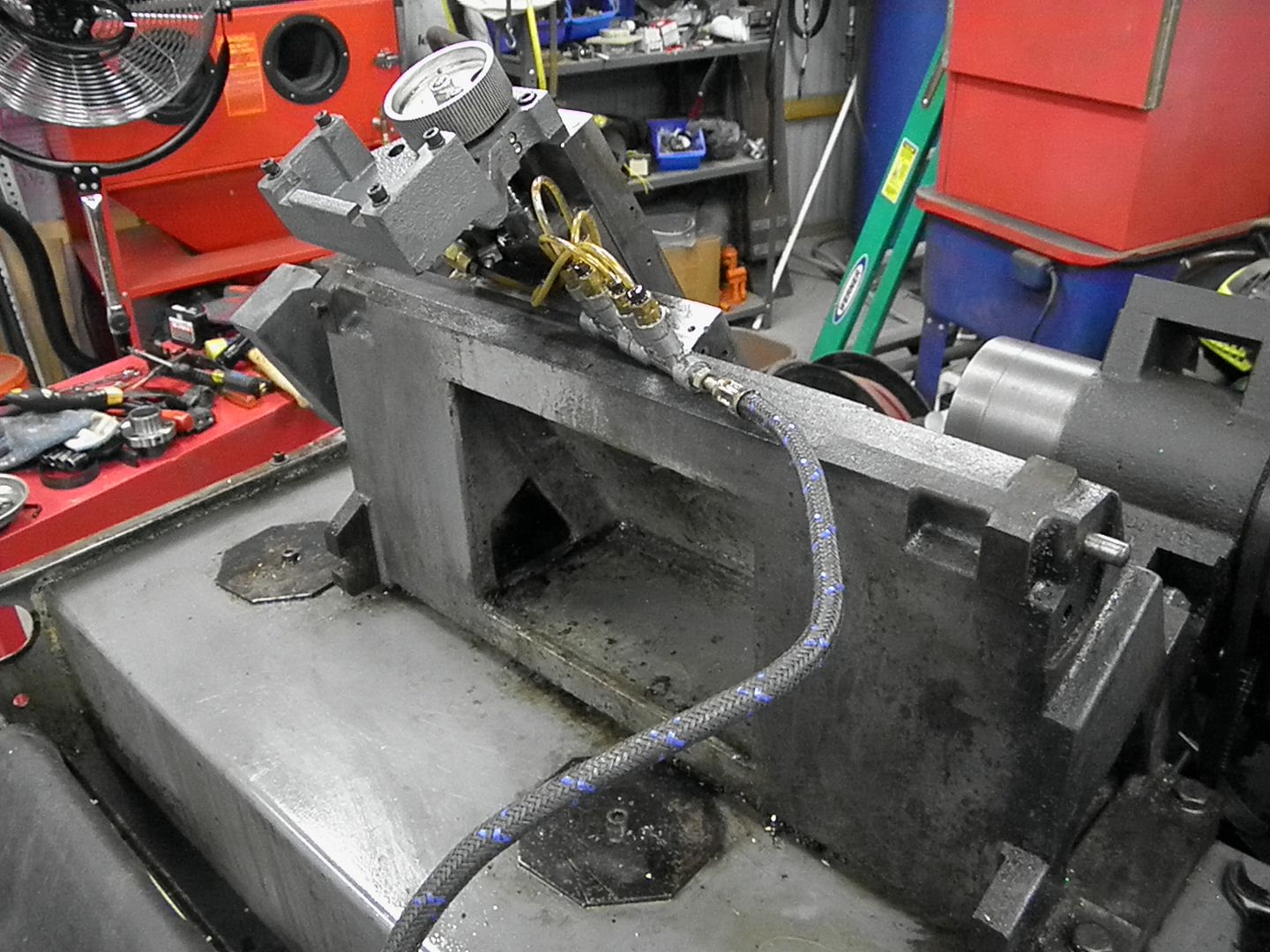

I also tried to clean the oil distribution block, that feeds oil to the ways, as two of the outlets weren't working. I wound up taking the unit completely apart and removing this small rubber check valve to get the oil to move through. It works for now

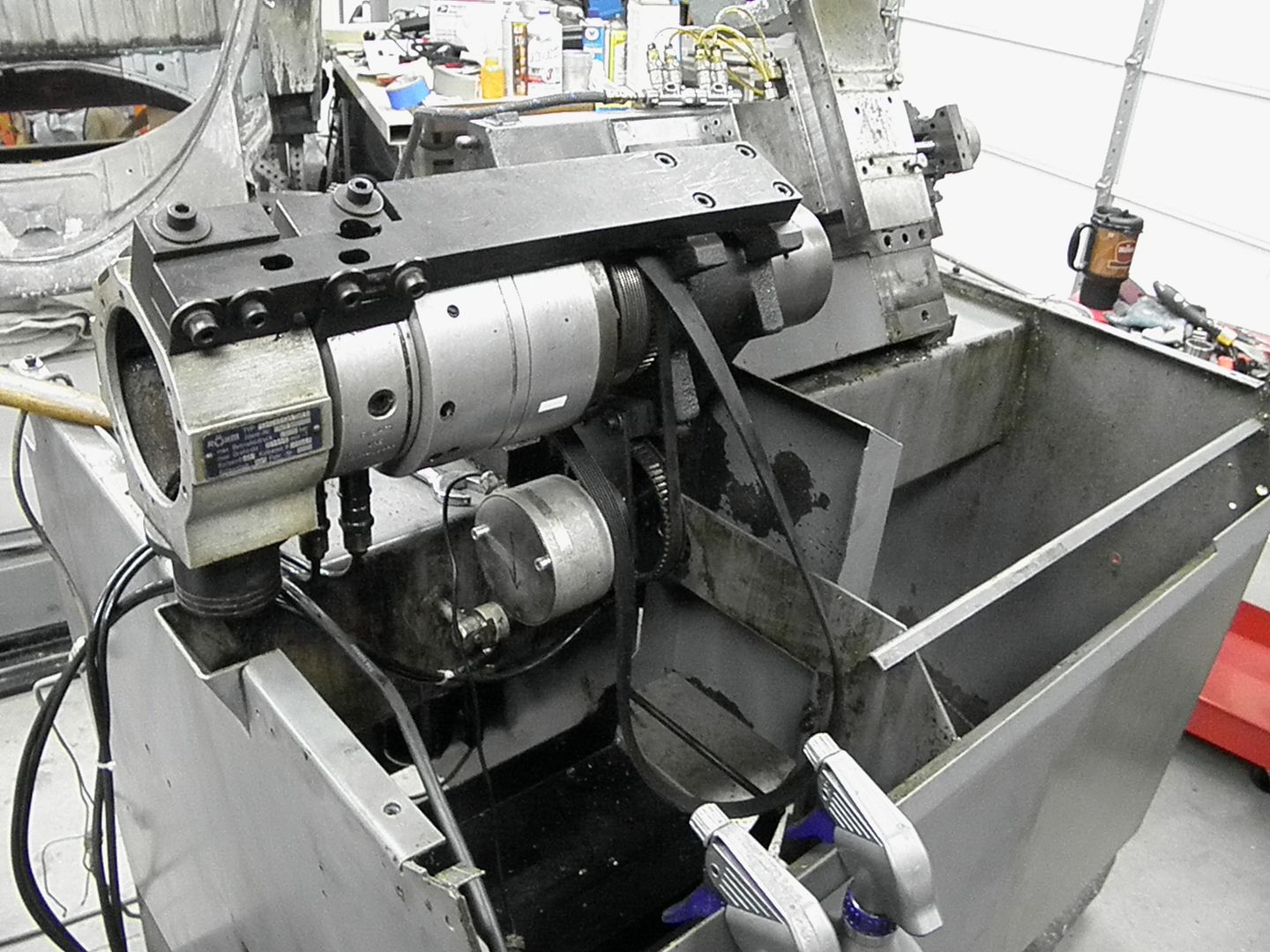

One of the main reasons for getting this lathe, other that the great price, was the parts catcher and the through spindle...which the 120p doesn't have.

Here's the parts catcher....

and the spindle.... i might make some type of bar feeder for it

Next on the list ...installing these.....

more to come....

Thread: Another Emco 220 Lathe Project.

Results 1 to 20 of 20

-

12-06-2013, 01:32 AM #1

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 367

Another Emco 220 Lathe Project.

pete

-

12-06-2013, 08:15 AM #2

Registered

Registered

- Join Date

- Oct 2012

- Posts

- 393

Cool machine (same as mine

), word of advice, I read in manual if you will be removing air cylinder after when you make maintenance , you need to dynamical balance it (what is not so easy, tools are expensive), so if you will not be putting new spindle bearings or there is no rust in spindle try not to remove air cylinder (mine was stacked so I would eventually disassemble it even if I did not change spindle bearings).

), word of advice, I read in manual if you will be removing air cylinder after when you make maintenance , you need to dynamical balance it (what is not so easy, tools are expensive), so if you will not be putting new spindle bearings or there is no rust in spindle try not to remove air cylinder (mine was stacked so I would eventually disassemble it even if I did not change spindle bearings).

I got with my machine 2 Hp (1. 5 kW)three phase AC motor, hope it would have enough power considering it is 1:1 motor shaft to spindle ratio (originally motor have 4 kW).

I will follow this thread with great interest.

Marko

-

12-09-2013, 12:40 AM #3

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 367

Hello Folks, Things were a bit hectic at my day job, but, I found some time to work on the lathe. I tested the chuck, tail stock and parts catcher and all appear to working fine.

I also mounted my limit switches. I'm only using two proximity switches for the X-Z limits and as well as for homing...to save on cost and the amount of wiring needed. I've done this to my other lathe and it worked out well.....Here are some pics of the setup.....

Attachment 212426

Attachment 212428

Attachment 212430

The proximity switches will be powered by 24 volts, thus , I'll need something like a 25K ohm resistor in series at the input to the breakout board.

I'm hoping to install the steppers, spindle motor and remaining wiring this week. Maybe, start installing the sheet metal next weekend pete

pete

-

01-01-2014, 11:18 PM #4

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 367

-

01-01-2014, 11:36 PM #5

Member

Member

- Join Date

- Jan 2005

- Posts

- 15362

slowtwitch

Looks like another great rebuild, are you going to do the same with the indexer as you did with the 120PMactec54

-

01-02-2014, 12:08 AM #6

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 367

-

01-02-2014, 05:43 AM #7

Member

Member

- Join Date

- Jan 2005

- Posts

- 15362

slowtwitch

Yes I meant to write were you using the same board to index the turret, I had to rush out, so cut it short, I tried to contact Andrew about his board, but have not had any reply backMactec54

-

01-03-2014, 02:39 PM #8

Registered

Registered

- Join Date

- Oct 2012

- Posts

- 393

Cant wait to see how you make something with machine.

I saw some kind of box above VFD, is that breaking resistor or pneumatic door closer, I did not get that with my machine. And why you removed tailstock?

Nice progress, I see you have heavy duty wheels.

:cheers:

-

01-03-2014, 04:09 PM #9

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 367

Hello Marko, That black box does hide a braking resistor

As for the tailstock, I really don't use one with what I'm going to machine and figured it would be a chip collector

As for the tailstock, I really don't use one with what I'm going to machine and figured it would be a chip collector

I bought the wheels on Ebay and welded them on. I couldn't be happier with how they work...moving the lathe is so nice....makes cleaning under the machine easier.pete

-

02-01-2014, 01:45 PM #10

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 367

Hello folks, It's been awhile

First of all, I'm tired of the cold !!!!!! Temps have been in the teens for the past two weeks. I can take it, but, my shop is unheated and I can't machine anything since my coolant is frozen. I have aquarium heaters in the tanks, but, they can't keep up

First of all, I'm tired of the cold !!!!!! Temps have been in the teens for the past two weeks. I can take it, but, my shop is unheated and I can't machine anything since my coolant is frozen. I have aquarium heaters in the tanks, but, they can't keep up

Fortunately, we're headed for a heat wave, temps in the high 30's and low forty's. Maybe i'll be able to thaw out the coolant and make some chips this weekend

Anyway, I made a quick video of the lathe. It's not the best quality, but, it gives you an idea of the end result....enjoy

pete

-

02-01-2014, 02:36 PM #11

Registered

Registered

- Join Date

- Oct 2012

- Posts

- 393

Hi Pete, I am so happy to see your Emco running. Hope to see more updates while machine is making things.

I think maybe your motor from emco 120 would be better on 220 because it is bigger.

Did you buy new electronics for 220 or you just used electronics from Emco 120, it seems like you have same control panel with electronics as on Emco 120.

I think they pored concert in the base for machine, I opened one cover and on top is something like black sand ,something like for making castings. I have huge hole at the back of my machine because of rust and tried to insert small screw driver, and inside is hard material, pretty sure it is concrete.

-

02-01-2014, 03:02 PM #12

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 367

Hello Marko, I used a bunch of stuff off the 120....steppers, drives and spindle motor. I did get a new break out board..a PMDX-126 and their 107 spindle speed control. The 120 will wind up being my second operation lathe.

pete

-

02-16-2014, 12:46 AM #13

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 367

Hello folks, Its been really cold here for a bit and as i have mentioned in a prior post , my coolant froze like a big ice cube

I haven't been able to make chips for a while ..thanks to the cold and my unheated shop. But, things had to be done as my work orders started to pile up. I acquired a small 1500 watt electric heater and aimed it at the 220's coolant tank... it took nearly 24 hours, but, my coolant tank is finally a liquid ..lol

Anyway, I took a video of the lathe doing it's thing. I was using the last of some stock that was cut for the Emco 120. that's why I ran short in the video

pete

-

02-16-2014, 08:20 AM #14

Registered

Registered

- Join Date

- Oct 2012

- Posts

- 393

Beautiful, I was just thinking how much time I would spent to do does two pieces manually

.

.

If you will do parts that have threads I would love to see how fast and how that looks.

Thanks for this video.:cheers:

-

02-18-2014, 10:20 PM #15

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 367

Hello folks, I made some minor changes to the lathe...well not really the lathe. I re-mounted the monitor. I originally had it mounted to the control box, but, that limited the monitors movement. I re-positioned it to the side of the lathe. Btw, these wall mounts can be had on ebay for about $12.00. I also added a keyboard tray. Nothing fancy, just some scrap 1/2" thin wall and a couple pieces of 3/4" plywood.

The tray is made up of two pieces of 3/4" plywood. The top piece is cutout to fit the keyboard. The bottom piece is attached with glue and short screws. Then the tray is painted to match the lathe The tray is attached to the thin wall using 1/2" clamps for thin-wall tubing...same as behind the monitor. Total cost was almost free... I had to buy the clamps, two bags of 4..about $1.80 plus tax

The tray is attached to the thin wall using 1/2" clamps for thin-wall tubing...same as behind the monitor. Total cost was almost free... I had to buy the clamps, two bags of 4..about $1.80 plus tax

I picked up the Storm 2200 keyboard on Ebay. These keyboards work really well on both my machines

Here are some pics...

Attachment 224520

Attachment 224522

pete

-

03-06-2014, 01:43 AM #16

Registered

Registered

- Join Date

- Mar 2014

- Posts

- 2

Hi, I just purchased an Emco 220, and was doing some research and saw your post. Your machine looks great and I am interested in how you retrofit it with the new pc and software. Any advice on where to start?

-

03-06-2014, 11:54 AM #17

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 367

Always glad to hear of a new Emco lathe owner... I think the most important thing with the conversion, is to become familiar with the Mach3 software....

(Machsupport Forum - Index

Secondly, get quality parts. I went with the PMDX stuff because of it's build quality...first rate.

Installing all the new stuff ..steppers , breakout board, computer, etc...isn't to bad. you just have to make sure that all your connections are correct, as one wrong misconnected pin will drive you up a wall

Lastly, you need to have patience. If you have the personality of throwing hammers against the wall, when there is an issue...this project is not for you

If you do decide to go forward and you need help, i'll give it my best shot to help you out pete

pete

-

03-06-2014, 09:31 PM #18

Registered

Registered

- Join Date

- Mar 2014

- Posts

- 2

Thanks for the advice. As I start this project I'll keep in touch and I'm sure there will be questions. If I can get it to run like yours, I'll be more than happy.

-

05-09-2014, 03:28 AM #19

Registered

Registered

- Join Date

- Aug 2007

- Posts

- 16

Re: Another Emco 220 Lathe Project.

Nice work! fantastic machine with bar feed. Wish i have the space in my home shop to fit one of these 120 or 220 beauties. I have to settle for the smaller 55 lathe. Still very glad that you refurbished this. Again nice work.

frank

-

06-18-2015, 02:15 PM #20

Registered

Registered

- Join Date

- Mar 2014

- Posts

- 2

Re: Another Emco 220 Lathe Project.

Pete this is just what I was after! I have the same machine only with the TM02 controller which I find to be a real pain! :/ but it have very little use as it spent it's like sitting in a room so it's a very clean machine and everything does work on it but the controller is a pain to use.. Thanks!

Dennis

Similar Threads

-

Emco F1 CNC mill school project

By Jakar in forum Benchtop MachinesReplies: 57Last Post: 04-12-2019, 12:03 PM -

EMCO LATHE VS. HARDINGE LATHE

By Crashmaster in forum Uncategorised MetalWorking MachinesReplies: 0Last Post: 03-04-2010, 05:33 PM -

Emco lathe

By fomaz in forum FanucReplies: 9Last Post: 11-23-2009, 10:39 AM -

Emco lathe

By jerry1122 in forum RFQ FeedbackReplies: 0Last Post: 06-28-2008, 11:38 PM -

EMCO 420 CNC Lathe

By CRT in forum G-Code ProgramingReplies: 3Last Post: 07-26-2006, 07:30 AM

Reply With Quote

Reply With Quote