I have a 3D part I need to cut. It's a canopy for a HexCopter UFO I am working on.

I own two 3D CAM packages; Cut3D and DeskProto. In this project I will be putting both to the test.

I will keep you updated with the details as I work my way through the process.

Here is a link to the blog page:

3D CNC Challenge

Thread: 3D CAM Software Throwdwn

Results 1 to 20 of 44

-

08-31-2012, 10:18 PM #1

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 686

3D CAM Software Throwdwn

Author of: The KRMx01 CNC Books, The KRMx02 CNC Books, The KRmc01 CNC Milling Machine Books, and Building the HANS Electric Gear Clock. All available at www.kronosrobotics.com

-

09-01-2012, 01:17 AM #2

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

Hey do you have a DXF of that file? Would like to see how my CAM handles it and compare it to what Cut3D does (which I also own)

Thanks...

-

09-01-2012, 01:40 AM #3

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 686

I have an stl of the file. Will your software handle that?

Author of: The KRMx01 CNC Books, The KRMx02 CNC Books, The KRmc01 CNC Milling Machine Books, and Building the HANS Electric Gear Clock. All available at www.kronosrobotics.com

-

09-01-2012, 01:42 AM #4

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

It will, though I won't have the control of toolpath I normally would with a solids or surfaces part. But I'll give it a shot... What materials are you using and the dimension of the stock?

My CAM will read directly DXF, DWG, VDA, IGS, SAT, STP, DGN, 3DM, as well as SolidWorks and Parasolids files...

I've been interested in DeskProto so awaiting your results...

-

09-01-2012, 01:53 AM #5

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 686

I can give you a dwg directly from AutoCAD if you prefer. PM me and we can set something up. I dont want to make the file public as I may be adding it to a book I am working on.

Author of: The KRMx01 CNC Books, The KRMx02 CNC Books, The KRmc01 CNC Milling Machine Books, and Building the HANS Electric Gear Clock. All available at www.kronosrobotics.com

-

09-01-2012, 01:54 AM #6

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 686

I just finished with the Cut3D results and not too bad. I will post the results once I get the blog page updated and the videos made.

Author of: The KRMx01 CNC Books, The KRMx02 CNC Books, The KRmc01 CNC Milling Machine Books, and Building the HANS Electric Gear Clock. All available at www.kronosrobotics.com

-

09-01-2012, 01:56 AM #7

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

-

09-01-2012, 03:12 AM #8

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 686

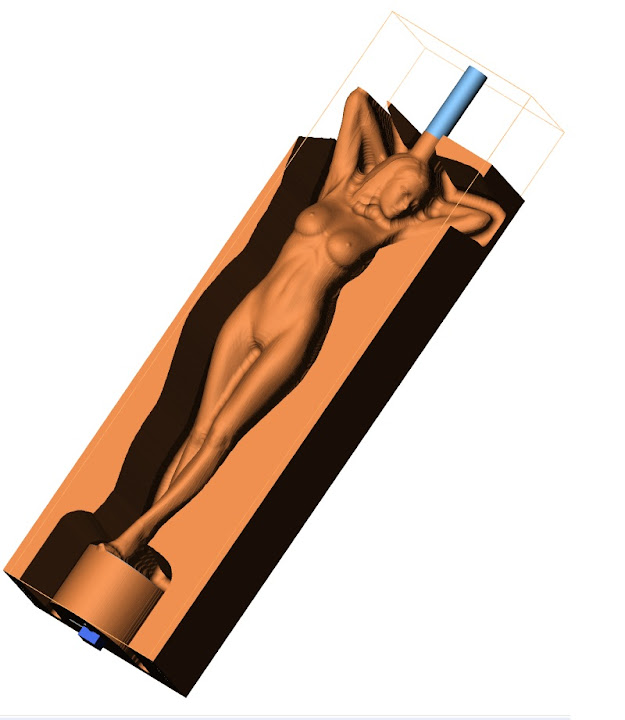

OK, just finished with Cut3D.

I did two jobs. One for the bottom:

And one for the Top:

Cut3d is pretty simple. Its wizard like interface makes it very intuitive. You do have to experiment with the settings in each step and the final rendering will help to let you know if you have done something wrong.

[ame=http://www.youtube.com/watch?v=sh5aZTT2rro]Canopy for HexCopter UFO- YouTube[/ame]

You can find the updated blog here:

3D CNC Challenge

Next is DeskProto. When I am done with both I will do a comparison.Author of: The KRMx01 CNC Books, The KRMx02 CNC Books, The KRmc01 CNC Milling Machine Books, and Building the HANS Electric Gear Clock. All available at www.kronosrobotics.com

-

09-01-2012, 05:57 PM #9

Registered

Registered

- Join Date

- Aug 2011

- Posts

- 999

I also have both software packages (Cut3D and DeskProto) and prefer each for different things.

- If it is simple one or manual two sided operation I always use Cut3D. Just simpler, faster and more intuitive. It usually takes me only minutes from .stl to G-Code.

- If it needs a rotary axis for indexed machining, continuous rotary 3D or a more complex tool path strategy then I need DeskProto. Cut3D just can not do that. But the increased capability comes at a price of long calculation times and a zillion parameters that can be changed and get confusing. If they are not set correctly it will screw up the project or just not create a toolpath. With all the trial and error it can take me hours to do the same thing. But maybe that is a matter of practice, too.

-

09-01-2012, 06:23 PM #10

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 686

One thing I have not seen in DeskProto is the ability to review your job. Its my goal to move more towards Deskproto. I just have a learning curve to deal with. Thats why I am using it on simple projects like this one.

Author of: The KRMx01 CNC Books, The KRMx02 CNC Books, The KRmc01 CNC Milling Machine Books, and Building the HANS Electric Gear Clock. All available at www.kronosrobotics.com

-

09-01-2012, 07:26 PM #11

Registered

Registered

- Join Date

- Aug 2011

- Posts

- 999

Yes you can, at least somewhat (see below). If you right click in the window and select "Subjects" you can choose to show the result simulation but only for one side. The calculation on my pretty fast PC takes about 5 minutes. Cut3D can show the entire result from all sides and is much faster.

Another thing that drove me crazy until I found out is to not use the "protect vertical surfaces" option for smooth 3d-shapes. I just leads to zig-zag tool paths and slow operation. In a way I like DeskProto because it is much more capable and flexible but I probably don't use it frequently enough to become proficient.

-

09-01-2012, 10:00 PM #12

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 686

That’s perfect!

I will give it a try.

Up until recently I have been primarily a 2.5D person. Just cutting out parts, drilling holes, pockets ECT. Since many of my book owners are just now nearing the end of their build. I have to start looking at the operation side of things in more detail. I’m also looking into adding a fourth axis upgrade to the design.Author of: The KRMx01 CNC Books, The KRMx02 CNC Books, The KRmc01 CNC Milling Machine Books, and Building the HANS Electric Gear Clock. All available at www.kronosrobotics.com

-

09-01-2012, 10:04 PM #13

Member

Member

- Join Date

- Apr 2004

- Posts

- 5740

On a surface like that dome, you'll find (with any CAM program you use) that the strategy that works best on the top works less well on the steeply sloping areas toward the bottom. So I'd suggest splitting the finishing stages, doing a parallel finishing toolpath on the top half and a horizontal (waterline) finishing toolpath on the lower slopes, with the paths set closely enough together to create smooth surfaces in both cases.

Andrew Werby

www.computersculpture.com

-

09-01-2012, 11:42 PM #14

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 686

One of my hopes was to combine normal 2.5 Techniques with 3D. The problem is that Cut3D does not do a good job at letting you isolate areas and shapes. So I have to design two models.

DeskProto seems to have a lot more flexibility in this area and even has some limmited 2D capabilities.

For now I am experimenting in foam because:

1. Its cheap

2. Its Easy to work

3. Its Easy to Sand

4. I need these parts for another project

I need to make some small thumb screws and I am thinking of doing them in 3D with a 1/16 carver bit. They will be done in hard wood or compressed PVC.Author of: The KRMx01 CNC Books, The KRMx02 CNC Books, The KRmc01 CNC Milling Machine Books, and Building the HANS Electric Gear Clock. All available at www.kronosrobotics.com

-

09-04-2012, 03:35 PM #15

Registered

Registered

- Join Date

- Dec 2010

- Posts

- 634

I think that the best strategy for something like this would be a spiral toolpath with the center point at the top of the dome. With a small stepover, you probably wouldn't even have to rough it.

-Andy B.

http://www.birkonium.com CNC for Luthiers and Industry http://banduramaker.blogspot.com

-

09-04-2012, 05:25 PM #16

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 686

Cut3D does not support anything other than a raster of your shape.

The best I can get it to do a raster like this.

Author of: The KRMx01 CNC Books, The KRMx02 CNC Books, The KRmc01 CNC Milling Machine Books, and Building the HANS Electric Gear Clock. All available at www.kronosrobotics.com

-

09-04-2012, 05:52 PM #17

Registered

Registered

- Join Date

- Dec 2010

- Posts

- 634

If you send me the file, bit type, origin position (probably center top of the dome would be best), stepover and feeds & speeds I can do a spiral path for you in VisualMill

-Andy B.

http://www.birkonium.com CNC for Luthiers and Industry http://banduramaker.blogspot.com

-

09-04-2012, 06:19 PM #18

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 686

Im pretty sure DeskProto can do spiral. When I get time I will be doing the same part in DeskProto.

Author of: The KRMx01 CNC Books, The KRMx02 CNC Books, The KRmc01 CNC Milling Machine Books, and Building the HANS Electric Gear Clock. All available at www.kronosrobotics.com

-

09-04-2012, 08:27 PM #19

Gold Member

Gold Member

- Join Date

- Apr 2009

- Posts

- 5516

-

09-04-2012, 08:48 PM #20

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 686

Its on my List

Author of: The KRMx01 CNC Books, The KRMx02 CNC Books, The KRmc01 CNC Milling Machine Books, and Building the HANS Electric Gear Clock. All available at www.kronosrobotics.com

Similar Threads

-

Need software advice...What software can import .JPG files?

By pairofjacks in forum Uncategorised CAM DiscussionReplies: 7Last Post: 06-01-2011, 12:18 PM -

machine control software & cam software

By grttt3 in forum CNC (Mill / Lathe) Control Software (NC)Replies: 2Last Post: 05-06-2010, 07:49 PM -

MIE Solutions - Free Quoting Software Trial Software available

By MIE Solutions in forum News AnnouncementsReplies: 0Last Post: 01-07-2009, 05:42 PM -

First post in the software dept. Free cnc software?

By runinbymdnt in forum CNC (Mill / Lathe) Control Software (NC)Replies: 2Last Post: 02-07-2007, 04:49 AM

Reply With Quote

Reply With Quote