I'm looking to add a Bison 5C collet chuck and Dorian quick change tool post to my 2012 Patriot.

I think I will remove the current compound and machine a riser block to mount the tool post. Any thoughts on what metal to use? I was considering 303 SS for corrosion resistance and it's a fairly tough metal.

Does anyone have experience with designing and machining an adapter plate for an aftermarket chuck like the Bison?

Results 1 to 16 of 16

-

09-30-2012, 04:46 AM #1

Registered

Registered

- Join Date

- Aug 2012

- Posts

- 27

Modifications - Collet Chuck/QCTP

-

09-30-2012, 12:56 PM #2

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 281

What you need is an aluminum disc about 1/2" thick and 5-6" diameter to make your adaptor- on one side duplicate the recess and bolt pattern of your 3 jaw chuck. Then bolt the adaptor to your spindle and machine the other side to match the Bison collet chuck. If you have the material in hand, the process will take you about an hour. You can also use the faceplate that comes with your machine and machine one side to fit you collet chuck. I hope JT won't be angry if I say this, but Smithy sells a collet chuck that will bolt right on- Their Midas machines are basically copies of the old Shoptask 12-22 series, and use the same 5" 3 jaw chuck, so the collet chuck they sell for those machines should bolt right up.

-

09-30-2012, 04:26 PM #3

Registered

Registered

- Join Date

- Nov 2007

- Posts

- 55

Ditto the Smithy collet chuck. Mine fits with just a tiny bit of clearance, less than a thousandth, but I snug up the bolts, then tap it until perfect before tightening.

Mine is the older style with the large nut on front, they now have a scrolling chuck. But it seems they may only sell it as a kit with collets and a holder, so it is more expensive than before.

Dennis

-

09-30-2012, 06:08 PM #4

Registered

Registered

- Join Date

- Aug 2012

- Posts

- 27

Thanks for the excellent info

Any idea what kind of TIR to expect with the Smithy setup? Are you able to get it running close to true tapping into place?

Any idea what kind of TIR to expect with the Smithy setup? Are you able to get it running close to true tapping into place?

-

09-30-2012, 11:47 PM #5

Registered

Registered

- Join Date

- Nov 2007

- Posts

- 55

I can get it as close as I can measure it with a dial indicator in the bore where the collet fits. Like I mentioned, the slip fit is less than .001", so I usually don't even bother, but it will track perfectly.

Now, my 4 jaw chuck is the opposite. I machined that adapter myself, and it's a few ten thousandths tight. I have to whack it with a brass hammer back and forth to remove it.

The lathe nose, by the way, is the Asian 100 mm standard pilot.

Dennis

-

10-01-2012, 02:09 AM #6

Registered

Registered

- Join Date

- Aug 2012

- Posts

- 27

Gotcha. Thanks again!

-

10-13-2012, 07:18 AM #7

Registered

Registered

- Join Date

- Aug 2012

- Posts

- 27

Got the Smithy chuck mounted up and running with about .0005 run out 1in from the collet which I can live with

I had a bit of trouble at first and couldn't get it past .008 so I took the chuck off the adapter plate and got that running dead nuts zero, put the chuck on and still couldn't get past .007. I ended up skimming a few thousands off the interface which gave me just a bit more room to move the chuck into place. Worked like a charm!

I had a bit of trouble at first and couldn't get it past .008 so I took the chuck off the adapter plate and got that running dead nuts zero, put the chuck on and still couldn't get past .007. I ended up skimming a few thousands off the interface which gave me just a bit more room to move the chuck into place. Worked like a charm!

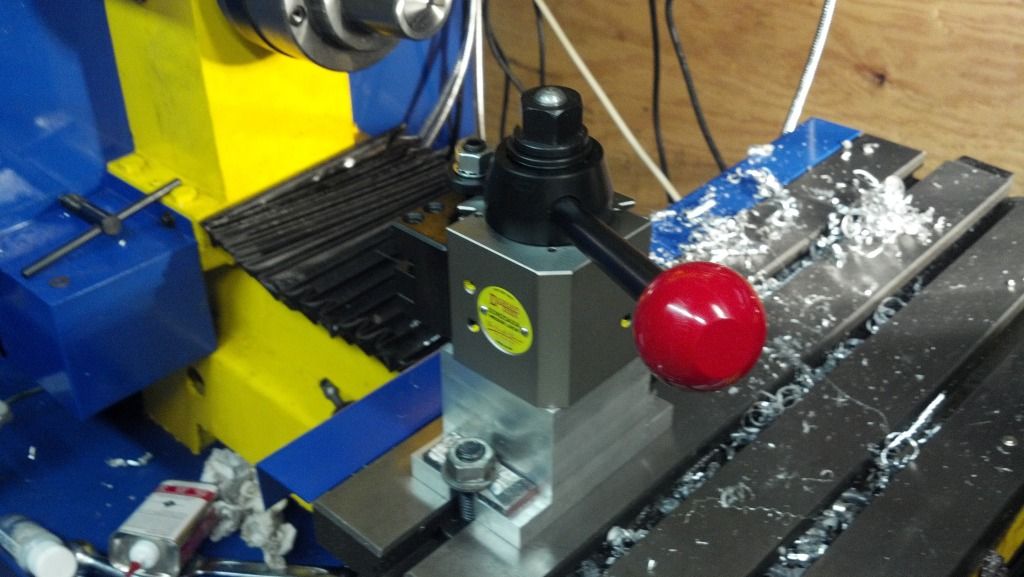

Next project is machining a riser block for the Dorian AXA tool post.

-

10-15-2012, 12:35 PM #8

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 281

Just curious, how much did they charge you for the collet chuck? Did you tell them it was for a Shoptask? I contacted them about buying a chuck and told the salesman that I wanted to fit it to one of our machines and he basically told me they would not sell to a Shoptask owner. Eventually had a friend place the order by telling them he had a used Smithy. The price was just over 150.00 with freight.

-

10-20-2012, 09:52 PM #9

Registered

Registered

- Join Date

- Aug 2012

- Posts

- 27

Either I overpaid or they changed things since you ordered

Did yours come with the plain back plate, collet set, stopper and rack? I just ordered straight from their website 5C Collet Kit (All 1220 Series) | smithy.com

Did yours come with the plain back plate, collet set, stopper and rack? I just ordered straight from their website 5C Collet Kit (All 1220 Series) | smithy.com

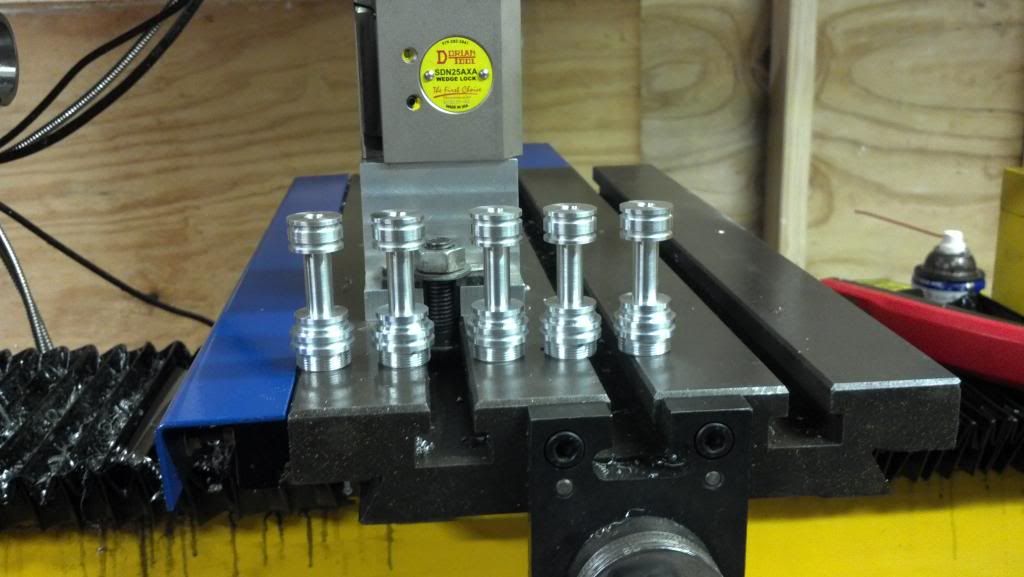

Finished the QCTP riser block yesterday. I may have gone a little overboard with the 6" reversed Glacern vise. Probably should have gotten the 4" instead heh. I'm sure I'm doing a bunch of stuff wrong and have made a few mistakes here and there (complete amateur, no experience...learning as I go), but it turned out just fine. I got to learn some things, try out CNC and manual controls, write some programs, etc. I like the machine, just wish it had gotten here sooner.

2012-10-18_19-29-50_599.mp4 video by TropospherePersonalVaporizers - Photobucket

That's 20 thousandth depth, .5 width at 24IPM in 6061-T6 with a 2 flute 3/4 endmill from the cheapo set sold at harbor freight.

-

10-21-2012, 12:18 PM #10

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 281

-

10-21-2012, 03:54 PM #11

Registered

Registered

- Join Date

- Nov 2007

- Posts

- 55

They now come bundled with the collets, etc, and are a better design anyway. Mine was only $135 or so, maybe $150. It doesn't have a back plate, the mounting recess is machined directly into the cast iron body of the collet chuck. Here is a photo of the older Smithy chuck sitting on the cross slide.

Dennis

-

10-22-2012, 04:50 AM #12

Registered

Registered

- Join Date

- Dec 2010

- Posts

- 30

Nice work.

Great job with the Dorian Tool Holder and 5C collet.

Made a similar arrengment with a SHARS (Aloris style) tool holder for my Patriot.

Are you saying the Smithy's 5C bolted right up to your Shopmaster Patriot?

Terrycan

(group)

-

10-22-2012, 04:52 AM #13

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 281

-

10-23-2012, 06:48 AM #14

Registered

Registered

- Join Date

- Aug 2012

- Posts

- 27

-

10-26-2012, 06:13 AM #15

Registered

Registered

- Join Date

- Nov 2007

- Posts

- 55

-

12-15-2012, 04:20 AM #16

Registered

Registered

- Join Date

- Aug 2012

- Posts

- 27

Added a swiveling work station mount and working on a tool holder/collet mount as well. Wired up the VFD for Mach 3 control and have been experimenting with CSS which is pretty cool stuff.

I was having some backlash issues, but those are pretty well sorted now though the X(Z) is still more than I'd really prefer at .0045...X is down to .0006. So now we're making parts for my prototype

Similar Threads

-

Hydraulic expansion chuck vs. Collet chuck

By gocuk in forum Metalworking- / Woodworking Tooling / Manual MachiningReplies: 3Last Post: 12-05-2011, 04:42 PM -

Online ordering power chuck, collet chuck, MC vises form Taiwan

By mtadirect in forum News AnnouncementsReplies: 0Last Post: 08-30-2009, 03:37 AM

Reply With Quote

Reply With Quote