I am currently in the process of building a FLA 300. The machine is fully built with the exception of finishing the cutting surface. The issue that I am having is with the g540. I have followed the tutorial on the gecko website but still arrive at the same problem of mach3 not recognizing that the e-stop is connected and not allowing the g540 to come out of fault mode.

Here is what I have done.

Wiring to power supply

Wiring from g540

E-stop wiring

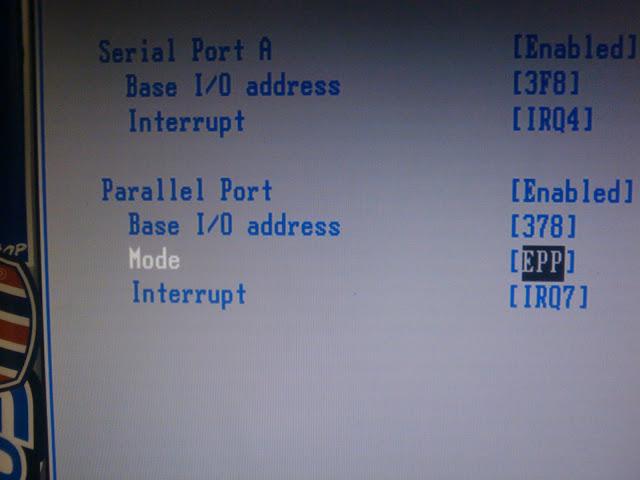

Parallel port setup on computer

Charge pump setup in Mach3

Error

I'm probably missing something very simple but I have been unable to figure out what it is. Any help would be appreciated.

Thanks, Tim

Results 1 to 20 of 20

-

01-11-2012, 02:29 AM #1

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 0

Need Help - Final steps before movement

-

01-11-2012, 05:18 AM #2

Registered

Registered

- Join Date

- Nov 2006

- Posts

- 1036

Looks to me like your e-stop is not wired correctly. You should connect your leads to the NC (normally closed) and the common contacts. You do not want to connect to the NO (normally open) contact.

Here's a link that might help you: http://www.cnczone.com/forums/diy-cn...ecko_g540.html

-

01-11-2012, 08:54 AM #3

Registered

Registered

- Join Date

- Nov 2011

- Posts

- 0

Hi Tim,

I have a G540 as well and this is how it is set up:

Power supply V- to E-Stop normally closed,

E-Stop normally open to G540 pin10

Power supply V- to G540 pin12

Power supply V+ to G540 pin 11

In mach for my E-stop I have, config>ports and pins>input signals, scroll down to E-Stop and tick enabled then tick 'Active Low'

Reset mach and it should get going. I don't have my machine 100% complete yet but my electronics are working when tested.

Hope this helps.

Rory

-

01-12-2012, 12:28 AM #4

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 0

I'm pretty new at this so I just took a shot in the dark attaching the gecko to the NO contact because I couldn't find a C contact. I tested some of the suggestions in the other thread and have figured out that e-stop is the problem. Using a jumper and turning the charge pump off gives me a green light instead of with the previous config I was getting a red light.

Roy,

I tried your method and it helped out with getting mach to work. The only thing is that I still don't have an e-stop that works.

I'm going to try to see if I can figure a way to get the e-stop to work, if not I'll see if I can find a new one.

Thanks for the help. I'll let you know if I figure it out.

-

01-12-2012, 07:50 AM #5

Registered

Registered

- Join Date

- Nov 2006

- Posts

- 1036

-

01-12-2012, 08:23 AM #6

Registered

Registered

- Join Date

- Jun 2010

- Posts

- 178

Your switch is not wired right, should be another contact at back.

-

01-12-2012, 09:37 PM #7

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 0

I can't seem to find it. There are four contacts. A NC an NO on one side (pictured in first post) and the direct opposite side looks the exact same. On the other two sides there are just the screws that stop together.

I have found a work around for right now. If I connect the gecko to a NC and the other NC to -V I can get a green led on the board. The only issue is that I have is since I have used the 'Active Low' in the configs of the e-stop in mach 3 the e-stop only stops the board and doesn't register in mach. It's ok for now but I'm still in the process of getting everything settle so I am still going to be looking for a better solution.

tim

-

01-12-2012, 09:51 PM #8

Registered

Registered

- Join Date

- Mar 2011

- Posts

- 584

Check for continuity between the NC terminal and to one of the terminals on the other side of the switch, with the switch pulled out. When the switch is pushed in it should be open.

-

01-12-2012, 11:08 PM #9

Registered

Registered

- Join Date

- Nov 2006

- Posts

- 1036

You should check, but I'm pretty sure you want to connect to the two "NC" contacts.

-

01-12-2012, 11:13 PM #10

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

Put a meter across the two NC contacts, which should have continuity with the button "UP". If so, then those are the 2 that you use.

Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

01-12-2012, 11:38 PM #11

As a few have pointed out, you have the E-stop circuit connected to two separate switch contacts, one N.O. one N.C. these are never common to each other, hence the E-stop circuit will never be closed, on the opposite side of the block to the N.C. there should be another N.C. terminal, these are the two to use.

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

01-13-2012, 12:12 AM #12

Registered

Registered

- Join Date

- Jun 2010

- Posts

- 178

Listen to Al, he's right.

Also, good luck!

-

01-13-2012, 01:12 AM #13

Registered

Registered

- Join Date

- Jun 2005

- Posts

- 176

Here's the internals of a standard single pole, double throw microswitch. You will see that in the relaxed state, the NC connection is made to the COM connection. When the switch lever is operated, the connection to the NO contact is made. Depending on how you want the software to behave when the switch is operated will make you use a combination of either the COM and NO contacts (switch conducting when operated) or the COM and NC (switch conducting at rest) my guess is that you want the switch to work when activated so use the COM and NO terminals.

-

01-13-2012, 02:18 AM #14

Registered

Registered

- Join Date

- Nov 2006

- Posts

- 1036

Actually, for the G540 you want a normally closed Estop!!!!

-

01-13-2012, 02:25 AM #15

Registered

Registered

- Join Date

- Jun 2010

- Posts

- 178

His switch doesn't have a COM terminal, just two sets of NO and NC terminals.

-

01-13-2012, 02:29 AM #16

Registered

Registered

- Join Date

- Jun 2005

- Posts

- 176

So its double pole single throw, strange. Do these come as part of a kit? Seems like a very non-standard switch.

-

01-13-2012, 04:11 AM #17

Actually this is very standard for a push button switch, whether E_stop or normal operator P/B.'s also many of the component type such as Telemecanique, Square D etc have blocks that can be added or stacked in N.O. or N.C. configuration.

What you are showing is the norm for limit/micro switch action types.

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

01-13-2012, 05:01 AM #18

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 0

Alright so I solve the issue with the e-stop. Thanks Al.

The next step is getting the motors moving with mach. Any threads that would help a beginner get moving?

-

01-13-2012, 05:21 PM #19

Registered

Registered

- Join Date

- Mar 2010

- Posts

- 371

This thread has already been pointed out to you. It's probably what you are looking for

http://www.cnczone.com/forums/diy-cn...ecko_g540.html

-

01-13-2012, 05:29 PM #20

Registered

Registered

- Join Date

- Dec 2010

- Posts

- 634

There's one last thing I needed to do to get the e-stop working correctly with my G-540.

In the General Config page, there is a checkbox labeled "ChargePump On in E-stop" which should be checked.

With this box checked and the e-stop enabled in the Ports and pins page, Mach 3 will recognize when you press the e-stop button.

Without this box checked, you can't get Mach 3 out of e-stop if the e-stop function is enabled in ports and pins.

If you disable the e-stop input (use emulated only) the e-stop will work on the G540 but, Mach 3 won't realize that an e-stop event has occurred when you hit the switch.

At least, that's what my experience with it was.

Seemed weird to me but it worked.-Andy B.

http://www.birkonium.com CNC for Luthiers and Industry http://banduramaker.blogspot.com

Similar Threads

-

Final Day - 20% OFF all Lasers!

By Hurricane21 in forum Laser Engraving / Cutting Machine General TopicsReplies: 0Last Post: 11-28-2011, 09:28 AM -

Final decision

By JINX222 in forum Haas MillsReplies: 12Last Post: 04-23-2007, 02:24 AM -

Final decision

By JINX222 in forum FadalReplies: 7Last Post: 04-14-2007, 07:27 AM -

Full Steps -vs- Micro Steps

By DJB282000 in forum CNC Machine Related ElectronicsReplies: 10Last Post: 12-29-2005, 06:25 AM -

final pipe

By D5zUga in forum Rhino 3DReplies: 0Last Post: 10-20-2004, 10:13 PM

Reply With Quote

Reply With Quote