Hi everybody, I thought I would share my current project which is a cnc benchtop lathe. After seeing the great work by other members and their custom machine projects I was motivated to try and build myself a nice little benchtop lathe. I already have a import 9x20 and I really have no interest in converting it. I wanted to just start fresh.:idea:

The lathe is a work in progress, I started on it about a month ago.

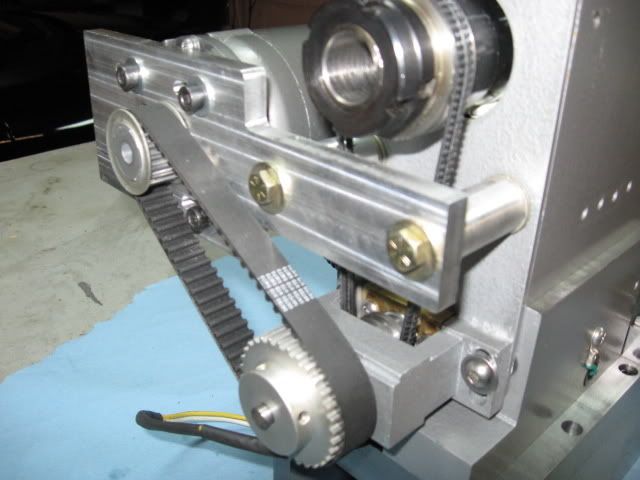

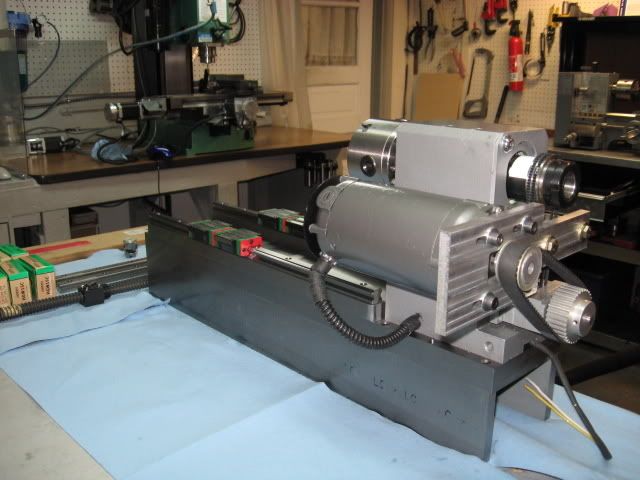

I adapted a mini lathe spindle and a mini mill spindle base to form the headstock for this project. Nice cast iron parts. I discarded the mini lathe plastic gear drive and built a new belt drive using a HTD primary and dual 3mm polyflex to drive the spindle. It will use a mini mill dc motor with a variable speed DC controller. The headstock is mounted through the bed with four studs. It's very solid.

The bed is made from 1" thick ground steel with 1/2" thick sides and boxed in underneath by welding. The bed is 5" wide and 24" long.

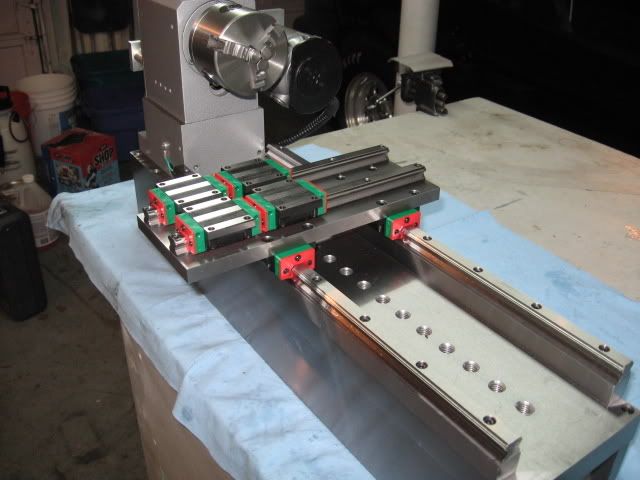

I mounted the z axis rails(Hiwin 15mm) today. I have them nice and parallel at around .0002" variance.

The tailstock will also be mounted to the z-axis rails on 2 blocks. The threaded holes in the bed are for locking the tailstock in place.

As shown in the pics it weighs about 100lbs right now. I'll be making a turret toolchanger. I figure the little feller will come in at around 150+lbs when done. So it'll be fairly easy to move around.

Well here are a few pics of my progress.

Steve

Thread: A benchtop cnc lathe build

Results 1 to 20 of 296

Hybrid View

-

07-16-2007, 03:39 AM #1

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 357

A benchtop cnc lathe build

A benchtop cnc lathe build

-

07-16-2007, 07:35 AM #2

Registered

Registered

- Join Date

- Jun 2007

- Posts

- 100

That is Nice Man, I'm a Huge Fan of well made, Shop Made tools. Any FOOL can go to harbor Freight, and start laying down $100 bills for Mediocre at best tools, But it takes a real Craftsman to Build a finely honed piece of Shop made tooling! I look forward to following your build. Please post lot's more pictures!

An idea that is not dangerous is unworthy of being called an idea at all, and Consistency is the last refuge of the unimaginative.

-

07-16-2007, 10:26 PM #3

Registered

Registered

- Join Date

- Sep 2005

- Posts

- 249

Very Nice!!! I can't believe you did that in a month! Did you have the steel ground for you, or pick it up stock? Nice idea with using the mini lathe and mill headstocks. I want to build one a lot like it.

-

07-16-2007, 10:32 PM #4

Look like a fairly large (DC?) spindle motor, what are using to control it?

Al.CNC, Mechatronics Integration and Custom Machine Design

“Logic will get you from A to B. Imagination will take you everywhere.”

Albert E.

-

07-16-2007, 11:41 PM #5

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 357

Thanks guys. I'm just having fun building it "on the fly" without any real plans.

I won't be able to work on it for a few weeks as I'll be to busy. I'll start up again on it in August. I'll get the x axis finished up next and then mount the ballscrews.

The steel is precision ground flat stock. I figured I could save myself some machining by starting off with nice ground stock. A bit more expensive but worth it to me.

Al, I'll be using a Minarik DC drive. I was going to use my old mini mill dc drive but some goofball without much electronics knowledge(me) smoked it by accident.

I'll use a proximity sensor to index the spindle to mach3.

Steve

-

07-16-2007, 11:54 PM #6

Registered

Registered

- Join Date

- Jan 2006

- Posts

- 481

hi

I have to agree with the guys very nice job so far SJH

Minarik DC drive ??? never heard of this brand , why not concider Gecko G-REX G100 , USB or Ethernet communication connection.

cheers

cheers

-

07-17-2007, 05:29 AM #7

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 357

FPV_GTp,

Thanks, I think Al was asking about the controller for the spindle motor, not the axis stepper motors.

For the spindle motor which is a 100volt dc motor, I will be using a manual DC drive for spindle speed, probably a Minarik drive.. For now anyways but that could change.

For the axis motion control and future tool changer l'll use a spare Xylotex 3 axis drive and 269oz steppers I have on hand. I will be using those with Mach3 Turn. Should work great with this machine.

Steve

-

07-18-2007, 12:13 AM #8

Gold Member

Gold Member

- Join Date

- Aug 2006

- Posts

- 1602

That's looking great Steve

I bought a mini-lathe headstock to do a similar thing, but rather tediously it isn't flat based like the mini-mill headstock - it has a dovetail groove cut into it. I think you've got it spot on by mixing and matching the spindles and castings from the mill and lathe

Do you mind me asking how you're going to synchronise the motor with the X-axis for thread-cutting - are you going to add an encoder somewhere?

Cheers.

-

07-18-2007, 05:43 AM #9

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 357

digits,

My mini lathe headstock did have a dovetail but I machined it away completely.

Same thing with the mini mill base. The cast iron in these 2 parts is quite good. Machines beautifully and is free of voids.

The motor is not indexed. The spindle gets indexed with a sensor. Mach will read how fast the spindle turns and adjust the axis speed to match the spindle for threading.

Steve

-

07-18-2007, 07:31 PM #10

Registered

Registered

- Join Date

- Feb 2006

- Posts

- 1051

Steve, didn't you write that up somewhere? I've searched the forums here but haven't run across it.

Sweet looking build so far. Is your base material that oil-hardening stock that MSC sells? I see that it's +/-.001 on thickness and squareness. Almost certainly better than I could square up material on my Tormach...

I've been considering something similar. I have a whole box of Thomson 10mm profile slides with preloaded carriages, so was considering using 6 carriages each on the Z and X axes (I've read about using 6 carriages anyway for "tolerance averaging" and that would get the allowable load up also).

Is there a reason that you are looking at a turret rather than gang-slide? There actually seem to be good reasons behind both, so I'm curious to know what swayed your decision.

Best regards,

Randy

-

07-18-2007, 06:44 AM #11

Registered

Registered

- Join Date

- Jun 2007

- Posts

- 100

SJS when you finish that lathe I'd love to commission you to build me one about 1/8 scale. That has been giving me Ideas that I shouldn't dwell on. but suffice to say as a model builder I've felt the need for a lathe about 1/4 scale of shurelines something like the Clisby but not as toy like or foreign! something Very accurate yet portable that can be carried out to the race track.

An idea that is not dangerous is unworthy of being called an idea at all, and Consistency is the last refuge of the unimaginative.

-

07-18-2007, 08:35 PM #12

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 357

wow that would be small! Sounds like a fun project though.SJS when you finish that lathe I'd love to commission you to build me one about 1/8 scale.

Randy, I am not sure if I ever talked about machining off the dovetails on the 2 bases. I may have mentioned it at the HSM site.

I am using Starret low carbon and oil hardening ground stock. It is very accurate dimension wise but the longer pieces do have some warp or Bow to them. So I did needed to flycut the z axis risers after it was all bolted together to keep the rails nice and even. What I could really use is a surface grinder. My x3 is fairly accurate though and I did not need to shim the rails at all.

The main reason I am going with a turret vs a gang slide is because I want to be able to use a tailstock if needed. Plus I think the designs for the pneumatic/stepper driven turrets are neat and I want to make one.:rainfro:

Steve

-

07-18-2007, 11:51 PM #13

Registered

Registered

- Join Date

- Feb 2006

- Posts

- 1051

:idea: I have always thought "the gang slide is just a long cross-slide, what's the problem?" but doh, the tailstock gets in the way of changing the tools past the end of the part... (I was a little slow in figuring that out...)

I guess that what would be needed would be a leadscrew-driven tailstock with a live center backed up by a stack of Belleville washers, and a limit switch that would close when the center was loaded enough to compress the Bellevilles. That way, you could retract the tailstock, change tools, advance and reload the tailstock to the right pressure and resume machining...

...or do it your way with the turret.

Best regards,

Randy

-

07-20-2007, 03:10 AM #14

Member

Member

- Join Date

- Jul 2007

- Posts

- 59

Steve

You should consider beefing up the spindle. In my opinion, the small cross section of the spindle is going to be the limiting factor in the rigidity of your machine. If you want to keep the workload down, at least consider turning a new spindle out of some good steel and leaving the center solid. That will let you keep the same bearing setup but have a more rigid spindle itself.

The bed and guides look great.

Do you have plans for guards to keep swarf off the bed

Keith

-

07-20-2007, 07:04 AM #15

Registered

Registered

- Join Date

- Feb 2006

- Posts

- 1051

Steve, I found the thread I was thinking of. It's MikeAber's mods to a mini-mill spindle on http://www.cnczone.com/forums/showth...t=10695&page=7 where he was modding it to allow higher speeds. (It's obviously the gray paint that had me confused!)

When you say "mini mill spindle base" are you talking about the piece that normally slides up and down the column?

Randy

-

11-28-2009, 07:49 AM #16

Registered

Registered

- Join Date

- Dec 2004

- Posts

- 229

Steve,

I have some questions about your pulleys. What size timing belt pulley are you using on your benchtop lathe headstock spindle, and where did you buy it? How many teeth did you choose?

I have the same kind of headstock as you on my benchtop lathe build, but I am having trouble finding a timing pulley that has a 1.050 bore. Did you turn the bore to size?

Thanks,

Dave

-

07-18-2007, 10:38 PM #17

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 357

cross slide base/rails installed

I managed to get a little time in the shop last night. I machined and mounted the cross slide base and installed the x axis rails. I am happy to say not even the slightest trace of binding on the z axis.:banana:

This is my first experience using linear rails and I am really impressed. So smooth and rigid at the same time.

Steve

-

07-20-2007, 04:19 AM #18

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 357

Keith, I have a lot of experience with a 7x lathe which this spindle came from. It's pretty rigid actually for it's size. Even made 8 rib blower pulleys for my strip car with it. On the 7x lathes the spindle is without a doubt the beefiest part of that machine. It's the same spindle / headstock used on the x2 mini mills as well. I only have a 350 watt dc motor powering it so I think it is well matched. I don't expect to hog off 1/8" cuts with this machine. But we'll see how it works once it is done. I will consider a heavier duty spindle if I find the need for it.

As for swarf, well the ballscrews will be covered and I am not concerned about the rails. I made the decision not to machine holes in the bed for swarf. The rails are almost 5" wide and elevated so there is a lot of room for swarf. The smooth bed surface should be a snap to cleanup/shopvac the swarf. It's only a hobby machine and won't ever see a production type use. Again only time will tell though how it all works out.

Steve

-

07-20-2007, 01:20 PM #19

Registered

Registered

- Join Date

- Mar 2005

- Posts

- 1136

Steve the lathe looks great. I haven't used linear motion rails either but wonder with your recent experience what your comments would be regarding alignment and binding etc. Strikes me that whatever the clearance is on them, lets say its .0002, the alignment would have to be better than .0004 else you'd get binding. Now i can create two planes, coplanar to .0004 over a distance but its not an easy thing. I'd guess parallelism is easier to obtain using an indicator on one rail to set the other? things get more complicated when you consider most applications seem to use rolled stock or even fabrications that haven't been normalized so you'd expect movement....or with a bolt together assembly its going to be slightly different every time its assembled - even using ground stock, its going to bend to a degree to the base to which is bolted, right? Not yours, but some applications i see posted here couldn't possibly be hold .0004 thou; ie long runs on no-so-solid a base, yet they seem to work...puzzles me how these linear bearings work will if what they are attached to isn't made to at least the same tolerances.

just wondering how much you planned for this and how you achieved the sufficiently accurate coplanar surfaces on which to attach the rails? or am i missing something that reduces how critical keeping it coplanar and parallel is?

-

07-21-2007, 01:40 AM #20

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 357

Randy, yes that is correct. Nice cast iron piece.When you say "mini mill spindle base" are you talking about the piece that normally slides up and down the column?

Mcgyver,

Good questions. And I do think it is critical. I spent 500$ on rails and 10 blocks. No sense in that if the machine won't be able to be very accurate. That is why I began with ground stock. Just to make this machine build go smoother and easier. I struggled with the question of bolting the bed box sections in or welding them( the bed is boxed from underneath). I knew welding would cause some distortion but on the other hand there is less chance of anything shifting. I decided to weld in the crossbraces as I am pretty sure bolting them in would have also caused distortion. But since the rails are mounted on .75" risers all I really had to make flat was those 2 risers. The bed surface where the headstock mounts I figured could just be shimmed if needed. So mounted the bed on my mill and cnc flycut the 2 risers very slowly and evenly. This results in the 2 rails surface being as accurate as my mill table.

Once I had the bed done I mounted the Z axis rails and the headstock. I used my incredible bionic eyeballs to first sight the headstock and 1 rail straight on the bed. I then installed a block on that rail and chucked up a piece of ground and polished rod in the chuck. I mounted a Test indicator on the block and proceeded to align the headstock to the single rail. That honestly took many hours of twiddling, torquing and 1 shim under the headstock of .001". Once I was happy with the results I began to align the other rail to the master. I used a jackscrew between the 2 rails and adjusted the other rail slowly 1 rail mounting bolt at a time. The result was the indicator shows very very little movement coplanar. I have more error in the vertical plane but on a lathe that is a second order error and of little consequence.

The proof I did a decent job was when I bolted up the 1/2" thick steel plate using 16 bolts to the 4 blocks and there was no binding at all.

For the cross slide rails I desiged the rails to be 1.5" apart. I did this so I could fit 2 parallel plates between the rails and make it very easy to clamp them straight to one another. The cross slide and base are short 10" and 8" sections. No problems there at all with ground stock.Bolt it up and go.It's flat.

The rails can tolerate some slight mounting errors. The heavier the preload the less they can tolerate. The specs are online for the Hiwin rails/blocks. My machine is much under the max tolerances for these units.

This is a little machine though. The Z axis rails are 18" long and the cross slide rails 10.5" long. A larger machine with long rails might be a PITA to setup. But people seem to do it all the time.

My first impression is wow, no wiggle at all. Very very rigid but they move real easy and smooth. If I tightened up my mill table or lathe carriage to be totally free of any "free" movement, well they won't move at all then.

Well I'll pickup where I left off in a couple of weeks. I am taking a long needed vacation! :wee:

Steve

Similar Threads

-

80/20 benchtop lathe build

By LeeWay in forum Vertical Mill, Lathe Project LogReplies: 87Last Post: 06-15-2015, 01:35 AM -

DIY benchtop mill build

By mkuivamaki in forum Benchtop MachinesReplies: 36Last Post: 03-19-2014, 08:54 AM -

Looking to build my own benchtop cnc!

By rim basses in forum Benchtop MachinesReplies: 0Last Post: 10-09-2009, 07:20 PM -

Not a Benchtop mill but Dang! You have to see this build.

By praetor in forum Benchtop MachinesReplies: 19Last Post: 05-19-2009, 10:58 AM

Reply With Quote

Reply With Quote