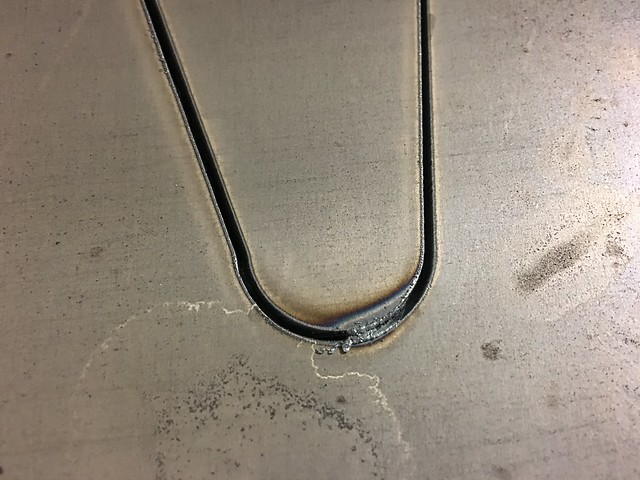

Having a strange issue where the Powermax 85 using fine cut is having a hard time keeping the arc though the plate.

I am cutting 11G Steel, I have tried it set to 10G using book settings, I have tried splitting the difference from 10G - 12G. Nothing I seem to do makes it cut correctly.

I also have an issue where on the parts it does cut we get lots of dross on the top and it likes to ball up and make the torch randomly stick ruining the part.

This was with a brand new copperplus electrode and tip.

When we use the regular 45 amp tip and shield it cuts fine. But we would love to get the fine cut working right.

Any ideas?

Thread: Powermax 85 Fine Cut Issue

Results 1 to 9 of 9

Threaded View

-

12-12-2016, 06:29 PM #1

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 86

Powermax 85 Fine Cut Issue

Similar Threads

-

Powermax 45 Fine Cut Consumables Question

By microdot in forum Hypertherm PlasmaReplies: 10Last Post: 02-25-2021, 06:51 AM -

sprutcam 9 tool library issue, waterline issue, was working fine

By TPR in forum SprutCAMReplies: 1Last Post: 01-08-2016, 06:58 AM -

Powermax 65 Fine Cut problem

By shanej in forum Hypertherm PlasmaReplies: 1Last Post: 05-23-2012, 11:19 AM -

POWERMAX 85 FINE CUT TROUBLE

By dnelso in forum Hypertherm PlasmaReplies: 13Last Post: 02-21-2012, 02:25 PM -

Fine cut chart for Powermax 600

By jarm22 in forum Hypertherm PlasmaReplies: 1Last Post: 12-01-2011, 02:41 PM

Reply With Quote

Reply With Quote