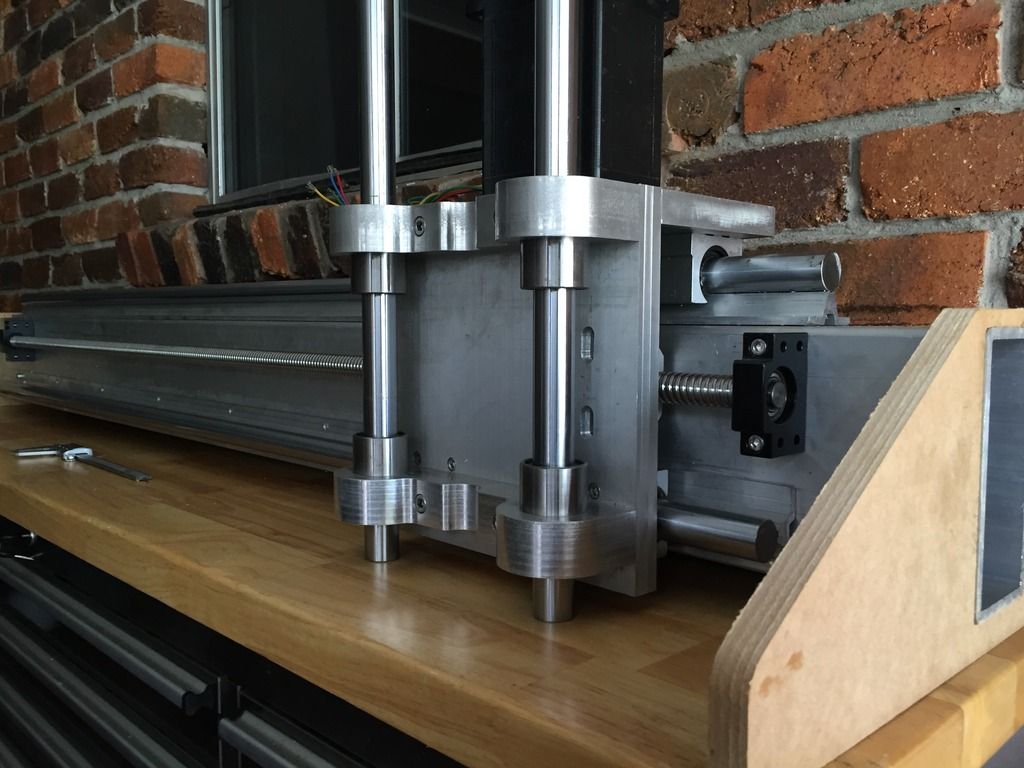

Here is some pics and vids of the machine i've been building for the last year or so.

Basic run down,

Y-Axis dual 2005 ballscrew 8NM (1200oz) drives per side. 1360MM usable area

X-Axis SIngle 2005 Ballscrew 20nm (2800oz) drive (overkill i know but i had it left over. 1360mm movement

Z Axis 2505 ballscrew single 8NM direct drive. 205mm movement

Ethernet MOtion card by XHC (once you work out there bugs its pretty good actually)

Hanyung VFD communicating via rs485

A simple 12V automotive Advantech PC, also works surprisingly well

Optical homing switches

Z Y and A Z axis all using closed loop. X will be upgraded as funds permit.

The bed itself will be 1350X 1040Y with a vertical bolting able to use the remaining 320mm in.

Spindle for now is a 2.2kw Chinese job, till i can afford a ATC spindle

So far all has been built backwards i build the gantry first and built the machine around that.

100% tig welded and very square, buet thing about the tig is you can consentrate the heat were you need to pull it be square.

Awaiting my table top 20mm ALuminium plate over 1700 holes on the top to be drilled and tapped.

- - - Updated - - -

video of it running

Results 1 to 20 of 24

Threaded View

-

04-16-2017, 10:18 AM #1

Registered

Registered

- Join Date

- Aug 2014

- Posts

- 103

Router home build Australia. Solid steel build

Similar Threads

-

CRP PRO4896 Build - Australia

By big-div in forum Avid CNCReplies: 2Last Post: 11-29-2014, 04:54 PM -

CRP4896 Build #2 - Australia

By rnm85 in forum Open Source CNC Machine DesignsReplies: 30Last Post: 04-16-2013, 10:53 PM -

first build solsylva table in australia

By evilbetty in forum CNC Wood Router Project LogReplies: 13Last Post: 07-16-2012, 08:40 AM -

8020 build (what, another one?!) in Australia

By Elrast in forum CNC Wood Router Project LogReplies: 8Last Post: 06-29-2012, 10:10 AM -

TM1 Kit Build - Australia

By SteelArt in forum TorchmateReplies: 5Last Post: 08-14-2009, 02:33 AM

Reply With Quote

Reply With Quote