A couple months ago, a co-worker told me about his CNC machine he built at home. He answered A LOT of my questions on the general building process and I then began searching online for more designs, tips and tricks.

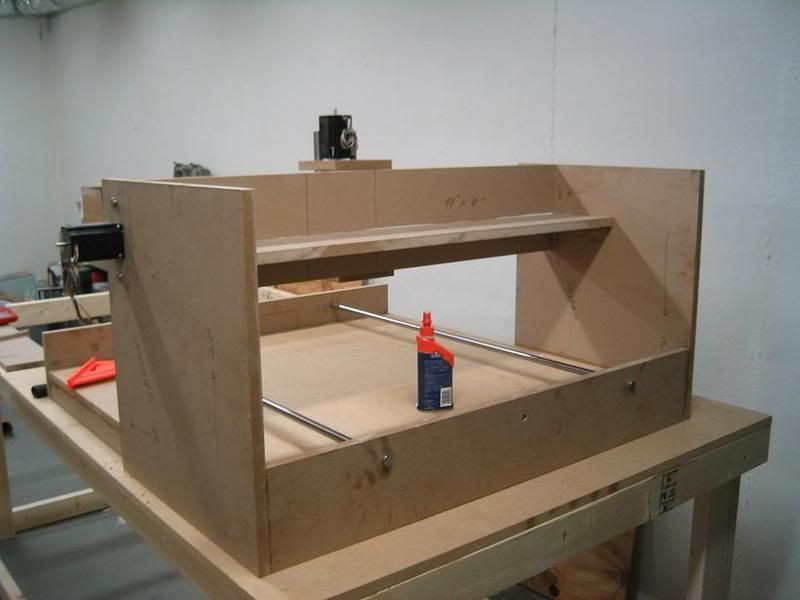

I finally embarked on my very first router. If anything seems wrong, please let me know, I won't get offended, I'm here to get things right and learn.

Here's a list of specs:

-Material used is 3/4" MDF

-I'm using a HobbyCNC controller with 305 oz-in steppers

-I'm hoping to cut mainly wood and plastic, and maybe try aluminum.

-The guide shafts are 5/8" diameter.

-I'm using PTFE linear bearings, since they are cheap, I figured I could just upgrade if they didn't perform well. (so far they seem okay)

-I bought a porter cable router, but I think it will be too heavy for the machine, so I'm probably going to using a dremel instead

-The Z-axis has not been designed yet.

-The platform (for the workpiece) has not been assembled yet.

-I'm using 1/2 - 10 precision acme rod

-I don't have exact numbers for travel, but its roughly 36" x 36" x 4". The overall dimension of the machine is 41.5" x 41.5"

What do you guys think? Overall it seems pretty sturdy. I'm using wood glue and nails to secure the thing together. The thing is so big I had to build its own table. The table is 4' x 8', I tried to make it big enough to also support a desktop computer.

-Levino

Results 1 to 20 of 34

Threaded View

-

10-19-2007, 04:37 AM #1

Registered

Registered

- Join Date

- Mar 2007

- Posts

- 18

Router Using 3/4" MDF (first router build)

Similar Threads

-

building a cnc router

By TheCrazzyman in forum Mechanical Calculations/Engineering DesignReplies: 3Last Post: 10-06-2006, 06:05 PM -

building first cnc router

By bradyfb in forum DIY CNC Router Table MachinesReplies: 0Last Post: 11-02-2005, 02:38 AM -

5' x 10' router building need help

By stevelang in forum DIY CNC Router Table MachinesReplies: 13Last Post: 08-29-2005, 06:55 PM -

Building My First Router

By CAMmando in forum DIY CNC Router Table MachinesReplies: 27Last Post: 08-03-2003, 06:19 PM

Reply With Quote

Reply With Quote