Hello

I have begun the adventure of converting a new lathe and mill to CNC. This thread is where the discussion began. We will convert the lathe first, using the mill to help the process along. After the lathe is done we'll convert the mill.

The main goal of this thread will be to collaborate on creative ideas involving the conversion of the Grizzly 10x22 lathe, and the X3 mill.

We manufacture tactical training products as shown in the photo below:

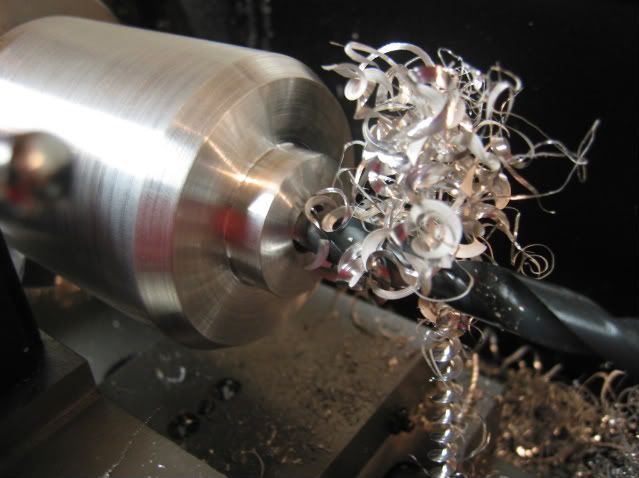

We have been using 7x14 lathes in our process, and have definitely outgrown them at this point. Here is one of our 7x14's taking care of a drilling operation:

Items that have been ordered so far:

1 G0602 10x22 lathe

1 G0463 mill (this is the Grizzly version of the X3)

1 G540 stepper motor controller

I was on the Keling CNC website, (which is a great resource for parts), but I couldn't find the KL23H284-35-4B 387 oz-in steppers on their order page? I left a message with them, but I was curious if anyone on the forum had any knowledge of why they aren't available?

I will be ordering my control computer from this site. We will be running Mach3, and I know that we need parallel ports, but is there anything else to look for in a control computer?

With the learning that will come from this work, I hope to offer much to the forum in the form of this thread and any questions that I can answer. In the mean time I'm sure that I will have many questions, but I'll do my best to search before I post.

We are in the process of ordering all of the necessary components for the conversion as well as modifying our shop to receive the new machines. Any tips on bench construction/modification would be great for a CNC conversion.

What is the best way to purchase Mach3?

We will be going with ball screws, and I will turn them down on the new 10x22, (great ball screw turning videos, scroll down). First I need some good quality tooling for the lathe with good indexable inserts. We will be ordering this quick change tool post. I have to admit that I am a bit unsure as to what tooling to purchase for the lathe. Any help with this would be great! The initial mill tooling will be this set from Little Machine Shop.

When looking into helical connectors to go between the stepper output shaft and the drive screw, do you choose connectors that will accept the OD of the stepper shaft and then turn down your screws to match? This makes sense to me but I want to be sure.

Is it fair to assume that, with attention to detail one can create a CNC machine from these machines that will work well and be reliable over a period of time?

Thank you all for your help now and in the future. More to come soon.

Results 1 to 20 of 144

Threaded View

-

02-15-2009, 08:52 PM #1

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 101

Grizzly 10x22 lathe, and X3 CNC conversion build log

Similar Threads

-

Grizzly 10 x 54 mill CNC conversion

By robhrzic in forum Bridgeport / Hardinge MillsReplies: 79Last Post: 05-20-2023, 10:37 PM -

Grizzly G0602 10" x 22" Lathe Conversion

By derekbackus in forum Vertical Mill, Lathe Project LogReplies: 145Last Post: 01-29-2019, 09:29 PM -

Just got my Grizzly X3. CNC conversion to come...

By stag53 in forum Benchtop MachinesReplies: 36Last Post: 12-21-2009, 07:30 AM -

Grizzly 10x22 or Lathemaster 8x14

By C.BRAXMAIER in forum Mini LatheReplies: 2Last Post: 09-19-2008, 03:04 PM -

Any opinions on the Grizzly g4016 lathe or other Grizzly lathes?

By DublD in forum Uncategorised MetalWorking MachinesReplies: 3Last Post: 11-26-2006, 07:23 PM

Reply With Quote

Reply With Quote