Wanted to introduce myself - Been doing a lot of lurking on these forums to get a better understanding of where the "budget-minded" CNC Plasma tables are at these days and I have to say I'm rather impressed with some of the work people have been doing on these machines!

A little background on myself - I received my masters in Mechanical Engineering not too long ago and have been working in the "real world" for only about 4 months now. I had a very interesting experience as a mechanical engineer in that most of my coursework (ESPECIALLY my graduate research) was almost all hands-on. Our university had a full machine shop, including my favorite piece of a equipment - an OMAX Waterjet. I saw one of the shop technicians using this device one day and I was absolutely blown away with the way it worked and how well it functioned. From that day on, I spent hour upon hours training myself on the machine, learning their software inside and out, and making a lot of mistakes on the way. Luckily, for me, mistakes were free since the material and machine time was all "included" in my tuition in one way or another - I always wondered what that $1000 technology fee was whenever I paid my semester bill, but I probably took the most advantage of that of any student on campus!

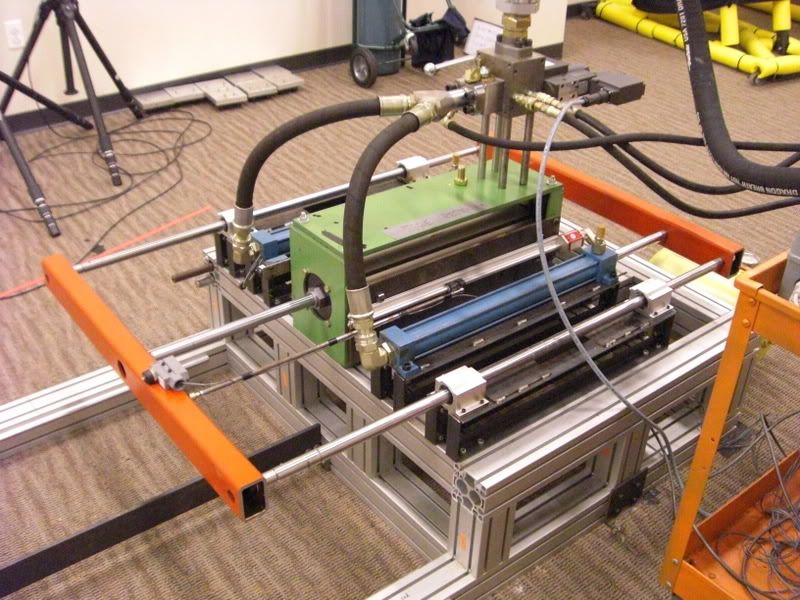

So, as I said, our university revolved many of its classes around hands-on learning. We didn't just learn about air compressors and steam engines - we built them. I didn't just read a textbook about testing automotive safety restraints and creating biofidelic crash test dummies, I built a crash sled of my own:

So now I work for a company who designs massive wastewater treatment plants where I don't think a bolt smaller than 3/4" exists. While it's still interesting to design such equipment, I'd much rather being doing smaller, more intricate parts that require a lot more attention to detail and accuracy.

Now that I've said a little (well, a lot) myself, lets get back to the point of this thread. Since I've graduated, I have missed that Waterjet. I often find myself drawing up sketches at work of parts that I could use on my truck - I think I have about 15 or so that could easily be cut out on a waterjet or plasma cutter. Basically, I miss fabricating and enjoy it a whole lot more than the engineering work I'm doing now. Some of these CNC tables look like a semi-affordable way to get back into that industry.

I've done a bit of research on some of the manufacturers and I think I've narrowed it down to three - Torchmate, PlasmaCAM, and EZ-Router. I like the Torchmate because it's portable and can easily go wherever I may end up, but I don't like the extruded aluminum frame (as you can see from my crash test sled, I've used Minitec extruded aluminum quite extensively and I've run into many issues with it). I also don't like that they use their own proprietary software. I'm kind of a computer snob and I'm always looking for updates and ways to expand on what I currently have. I do like that there is basically no lead-time on their table and it has the ability to use a machine torch.

Now, onto the PlasmaCAM - this seems to be the most popular "budget" table on the market. Their table frame seems fairly rigid, but looks a little on the cheap side in my opinion. Again, they also use their own proprietary software, which can be good if it's full of features and has the ability to be expanded on. I'm led to believe they have a very small lead time on their tables and the machine is pretty easy to put together. I don't like that their system uses a hand torch setup, though. I feel that the machine will be much more accurate with a machine torch setup.

I think my favorite of the bunch is the EZ-Router system. Their table is big and robust and they use an "open" software, which I'm still doing my research on and trying to determine why it would be a better option for me. I believe there are trial versions of the software that are available for download so I should take a look at those to see how they're laid out and what kind of features they have. Only downsides of the EZ-Router system is about a month lead time and it's a beast - all 800 pounds of it. I have a dedicated room for this machine in my shop, with 220VAC/100amp outlet and a 4'x3' exhaust hood. I would just be concerned with getting the machine into the room if it's going to come to me fully assembled.

Well, there you have it - just me expressing some of my thoughts on a few machines. Are there any companies that I missed and are still within the 8-12K price range? I'm not exactly rolling in cash, so this purchase will be a HUGE initial investment for me so I need the price to be within reason.

Before I go and hit the submit thread button, I'd also like to mention that I'm extremely proficient in AutoCAD and SolidWorks and would be using either one of those two programs to do all of my design drawings in and then transferring them to the cutting software to layout my cut paths. I also intend on using Thermal Dynamics Cutmaster 82 for this machine and I would prefer that a machine torch be dedicated to the CNC so that I can still use my handtorch around the rest of my shop.

If you've gotten this far, thanks for reading all of this!

Results 1 to 20 of 22

Threaded View

-

02-27-2009, 06:31 PM #1

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 102

New guy looking for an entry-level table

Similar Threads

-

Entry level router

By logansams in forum Commercial CNC Wood RoutersReplies: 3Last Post: 09-18-2008, 03:20 AM -

Looking for an Entry Level CNC machine

By pk_volt in forum Uncategorised MetalWorking MachinesReplies: 4Last Post: 06-19-2008, 07:41 AM -

Looking for entry level cnc set-up and programmers

By Melissa Lawson in forum Employment OpportunityReplies: 0Last Post: 03-20-2008, 06:10 PM -

Entry Level CNC Lathes

By big_mak in forum Uncategorised MetalWorking MachinesReplies: 45Last Post: 12-28-2007, 06:48 AM -

Entry Level 3d Digitizing

By robinsoncr in forum Digitizing and Laser DigitizingReplies: 14Last Post: 03-19-2007, 10:39 AM

Reply With Quote

Reply With Quote