"I searched Shopbot and Mechmate forums looking for a post regarding this, but haven't found anything yet."

MechMate CNC Router Forum : Archive through March 02, 2007

I can't seem to find the exact post (somewhere there are pictures), but the spindle replacement fan referenced here is a Papst 110v 3200 RPM:

3606 ebm-papst Fans & Blowers

Here is another who has done it too, but with a 5kw :

Yahoo! Groups

Thread: Chinese Spindle Recommendation

Results 21 to 40 of 50

-

02-15-2012, 07:46 AM #21

Registered

Registered

- Join Date

- May 2005

- Posts

- 120

-

02-15-2012, 07:47 AM #22

Registered

Registered

- Join Date

- May 2005

- Posts

- 120

CNC Spindle and Controller

Here is the Kelinginc website

-

02-15-2012, 08:04 PM #23

Gold Member

Gold Member

- Join Date

- Mar 2006

- Posts

- 119

Well, I received the spindle today. Mixed feelings on this one-

1) The listing said that the motor went to 400HZ, but the label on the motor clearly states 300HZ. I am not sure what to think of this. I suppose I can live with 1800rpm, I just find it annoying that the ebay listing was incorrect.

2) The cheap plastic impeller on the top of the spindle is either warped or installed crooked. You can actually hear it scrape as the shaft is turned by hand. No USA quality control facility would have let this leave the factory like this.

3) Although this was just a hope, it only came with one collet unlike the set that vid mentioned.

I would like to send it back, but the cost to mail it would probably be incredi-frickenble. I sent a message to the seller, I will see what their reply is.

I have to do some more digging to find some threads related to the replacement of the impeller with an electric fan. I would actually prefer an electric fan, so if I wind up being stuck with this thing, that will be my first course of action.

The spindle itself seems like a solid unit, the electrical connector is very nice. If I can get over the 300HZ limit and replace the impeller, I would think it has potential to be a useful tool. I just have to weigh the seller's response and think about it a little more.

-MikeExpensive tools can be cheaper than professional therapy

-

02-15-2012, 11:25 PM #24

Registered

Registered

- Join Date

- May 2005

- Posts

- 120

Mike, sorry you did not get the extra collets like other sellers include.

The HSD 3kw spindles, that these are copied from, are also 300hz, so they may have just copied the same data on to their paperwork. I see some ebay ads call them 400hz and some 300hz. Who knows? I've got friends in the woodworking club who run them at 400hz, apparently without harm.

Even the real HSD spindles, that the Chinese have copied, have plastic impellers in the top of the spindle: MechMate CNC Router Forum : (Noisy) Shaft mounted fans on Fimec & HSD spindles

Did it come with a manual?

We need lots of pictures of your Spindle for reference!

-

02-15-2012, 11:51 PM #25

Registered

Registered

- Join Date

- May 2005

- Posts

- 120

MT1090 - Y6162Y0019

Here is one of the real HSDs, note the 18,000 top speed.

-

02-15-2012, 11:56 PM #26

Registered

Registered

- Join Date

- Oct 2006

- Posts

- 735

If you are looking for a square spindle. Perhaps look at Ekstrom carlson's spindles. I've hada C73 on my machine I built in 2006 and it's been trouble free. I coupled it with a VFD from automation direct which are Great VFD controllers with nice features.

I also just got a C78 for my larger mill. And coupled that with a Siemens VFD seeing they were the only VFD who made one that could support a 4hp unit on single phase power that I could find. Had this spindle for amost a year now and it has been great.

Ekstrom also sells VFD's for their spindles but I found the automation and siemens I got from other sources to be cheeper then what they offered.

Yes they are a little more then the china ones but they are made in the USA, serviced in the USA and mine at least have been trouble free.. I expect them to last the better half of my life.

Will proably be getting a second spindle for my larger machine eventually. Probalby will connect the units to the same VFD and use a multi pole relay to switch between the units or something like that. I figure no real use to have 2 VFD's when I would only run the motors at separate times. Just have to program the IO in the Kanalog to only trigger the change over while the VFD is not active.

b.

.b.

-

02-15-2012, 11:57 PM #27

Gold Member

Gold Member

- Join Date

- Mar 2006

- Posts

- 119

^ great link

I will take a bunch of pics later tonight when I get home.

I think I will make due with this one, and take the plastic impeller off (man, is it way cheezier than the ones in your link). I'll search my electric fan collection and go from there. Heck, I also have some nice heatsinks that I might be able to mount to the flat sides of the body.

The 300HZ issue, hmm- I think I can live with that. I think that making a stink out of it and trying to get a refund out of this would be a stressful nightmare, so I might as well try to make the best of what I have. At least I now have SOMETHING in my physical possession. Stand by for the pics...

-MikeExpensive tools can be cheaper than professional therapy

-

02-16-2012, 12:01 AM #28

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 35538

Gerry

UCCNC 2017 Screenset

http://www.thecncwoodworker.com/2017.html

Mach3 2010 Screenset

http://www.thecncwoodworker.com/2010.html

JointCAM - CNC Dovetails & Box Joints

http://www.g-forcecnc.com/jointcam.html

(Note: The opinions expressed in this post are my own and are not necessarily those of CNCzone and its management)

-

02-16-2012, 12:15 AM #29

Gold Member

Gold Member

- Join Date

- Mar 2006

- Posts

- 119

-

02-16-2012, 12:27 AM #30

Registered

Registered

- Join Date

- Jan 2011

- Posts

- 242

If you paid with a credit card and the seller misrepresented their product, you have the leverage. Your credit card company will be more than happy to fight for you if you want them to.

-

02-16-2012, 01:12 AM #31

Registered

Registered

- Join Date

- May 2005

- Posts

- 120

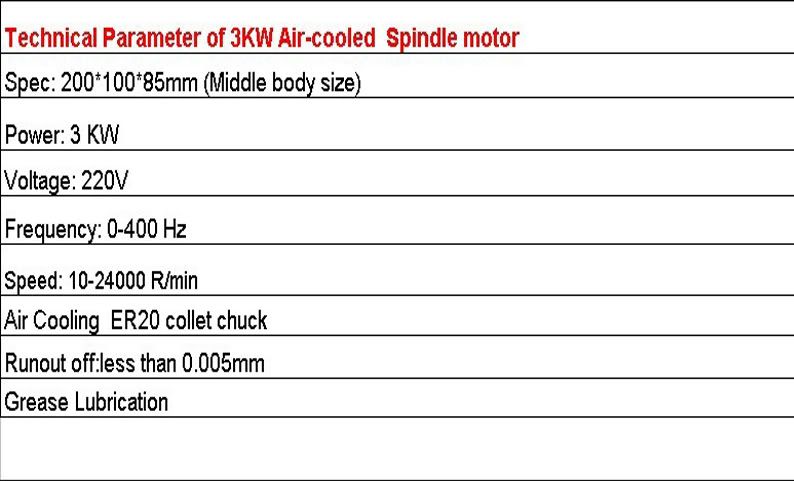

Here is the 3kw spindle I got from qiandingzhensatisfaction

It came with five ER-20 collets: 4mm 6.5mm 8mm 12mm and a 1/2 inch. It cost $389 with free shipping.

Like others, I got no manuals with it.

-

02-16-2012, 01:53 AM #32

Gold Member

Gold Member

- Join Date

- Mar 2006

- Posts

- 119

^ That looks like this one's brother, just without the label.

Here's a few pics attached- I also put a bunch in a photobucket page here.

I made a video to show the fan binding/scraping noise also, it is on the photobucket page.

The dust/crap in the pics is from the styrofoam packing material that I have not wiped off yet.

-MikeExpensive tools can be cheaper than professional therapy

-

02-16-2012, 04:13 AM #33

Registered

Registered

- Join Date

- Feb 2012

- Posts

- 0

-

02-17-2012, 03:44 AM #34

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 25

Mike -

Thanks for sharing the pix.

I'm really thinking about whether to try the 3kW air cooled spindle rather than a 2.2kW water cooled version.

Do you know how many bearings that unit has?

Can you tell how the fan impeller is mounted - press fit, pin, set screw?

Thanks

-

02-17-2012, 05:27 AM #35

Gold Member

Gold Member

- Join Date

- Mar 2006

- Posts

- 119

Hey Rob,

I'm not sure about the number of bearings. It had continuity between the body and shaft, so I am guessing that this would indicate steel VS ceramic balls.

The fan has no visible means of fastening, it may have been heated and pressed on.

I ordered several feet of Belden VFD cable a few days ago. I made an offer of $3 a foot VS $4 buy it now price, and it was accepted instantly. I will let you know how it fires up.

I was torn between the 2.2 water-cooled and 3kw air-cooled as well. I won't be able to say if my decision was right until I have this thing making some chips. As long as it doesn't have any vibration issues, I think it will do so just fine. I did receive a couple more emails from solar.jean, and they were cordial and reassuring. If this thing gives me any issues, I am fairly confident that the seller will help me out.

Thanks, MikeExpensive tools can be cheaper than professional therapy

-

02-17-2012, 06:57 PM #36

Registered

Registered

- Join Date

- May 2005

- Posts

- 120

The price of ceramic bearings would almost be equal to the router itself, but one day when your bearings are shot, installing ceramics is a possibility.

You would then need an alligator clip to do your touch plate.

-

02-20-2012, 01:10 AM #37

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 1256

spindled

Here is some pic's of an HSD 8Kwatt atc and a chinese spindle.Witch is witch?

Rather than being labeled Made in China,they should be labeled

"Copied in China"L GALILEO THE EPOXY SURFACE PLATE IS FLAT

-

02-20-2012, 03:59 AM #38

Registered

Registered

- Join Date

- Aug 2010

- Posts

- 25

Now I'm questioning whether to get a 2.2kW water-cooled or a 3kW air-cooled!

I originally decided to go with a water-cooled for lower sound and lower rpm.

I really only need 1.5kW, but I wanted an er-20 collet for my collection of 1/2 inch router bits. i will be doing a little aluminum machining. At work I have access to a couple of larger mills (Bridgeport, Frejoth). When I have machined aluminum on these machines, I have run the spindle around 1000 - 3000 rpm depending on the bit diameter. I concluded that it would be better to get a spindle that could get closer to these low speeds.

It would be nice to not have a cooling system hanging off the gantry. I would like to eventually be able to swap the spindle with a laser or other device (3d printing head??). Not having the radiator would really make this easier. I dread the sound of the shaft driven fan.

Anyone have experience with replacing a shaft driven fan with an electric one (like the ebm-papst fans)?? Were you able to get enough cooling air thru the 4 passages in the square spindle body? How low of rpm can you go? How loud is your replacement fan?

-

02-20-2012, 05:43 AM #39

Registered

Registered

- Join Date

- Jul 2006

- Posts

- 1256

Bob the lowest speed of these spindles is 6000 to 8000 Rpm

L GALILEO THE EPOXY SURFACE PLATE IS FLAT

-

02-21-2012, 05:23 AM #40

Gold Member

Gold Member

- Join Date

- Mar 2006

- Posts

- 119

Its Alive!

Hey Rob,

I finally got this guy wired up and fired it for the first time this evening. Maybe this will give you a little better idea what these are like:

I hope I embedded the video correctly!

-MikeExpensive tools can be cheaper than professional therapy

Similar Threads

-

Mini Mill X2 Spindle Head + VFD + Chinese Spindle= custom!

By diyengineer in forum Uncategorised MetalWorking MachinesReplies: 9Last Post: 12-26-2016, 10:04 PM -

CHINESE SPINDLE 2.2KW

By Ed Williams in forum Open Source CNC Machine DesignsReplies: 77Last Post: 03-29-2016, 04:07 PM -

So you want a Chinese Spindle !!!!

By eloid in forum DIY CNC Router Table MachinesReplies: 328Last Post: 11-04-2013, 06:32 PM -

spindle and VFD recommendation

By telah in forum DIY CNC Router Table MachinesReplies: 9Last Post: 07-04-2011, 02:55 PM -

Chinese Spindle/VFD Help

By swaggs21 in forum DIY CNC Router Table MachinesReplies: 7Last Post: 01-12-2011, 02:25 AM

Reply With Quote

Reply With Quote