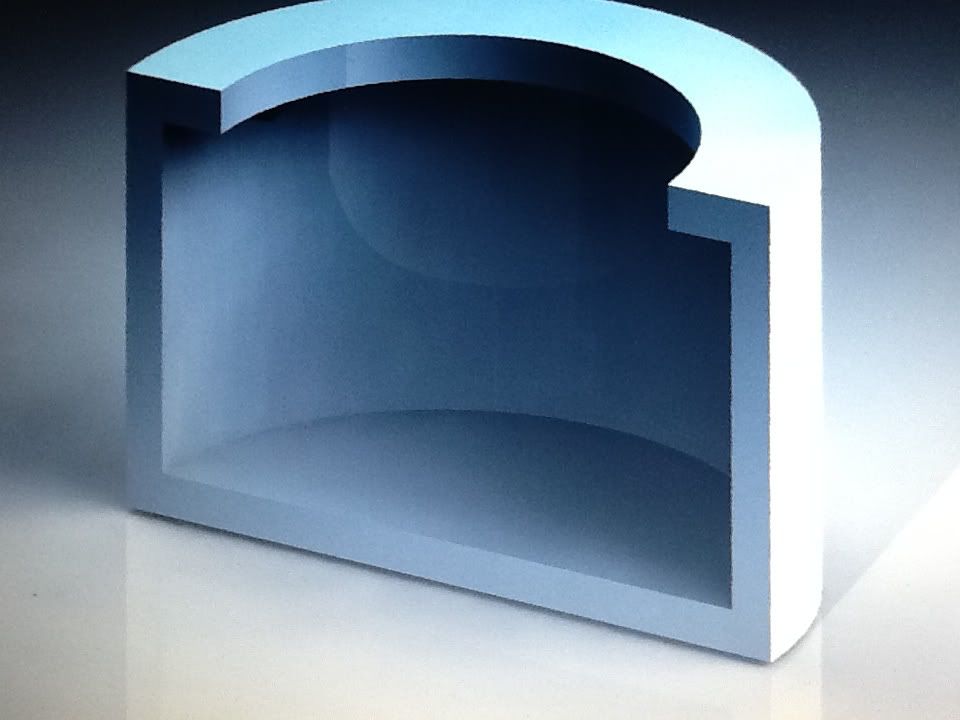

This is just cutaway part, it's cylinder.

Can Mc cut this?

How ?

C

Thread: How can MC cut this part?

Results 1 to 16 of 16

-

04-03-2012, 02:27 PM #1

Registered

Registered

- Join Date

- Feb 2005

- Posts

- 234

How can MC cut this part?

-

04-03-2012, 03:38 PM #2

Registered

Registered

- Join Date

- Dec 2008

- Posts

- 717

Mastercam can be programmed for a mill or lathe to cut that part but my mastercam doesn't actually cut parts - my mills and lathes do.

Seriously, though. Lathe part. Done...or use a saw on a mill(wedge)Tim

-

04-03-2012, 04:40 PM #3

If you do not know how to make the part on a manual machine, using MasterCam will not help you make it on a CNC machine.

-

04-04-2012, 02:50 AM #4

Registered

Registered

- Join Date

- Feb 2005

- Posts

- 234

I've been cutting parts using cnc router with mach3.

Toolpath created with rhinocam so far.

Can i use MC to cut this "pocket" part ?

I meant to create toolpath, not to cut.

that's the word, sorry ....

I don't think rhinocam can cut this part.

The part above is a cutaway section, so it's a cylinder part with pocket.

C

-

04-04-2012, 04:18 AM #5

What tool do you plan to use for machining?

-

04-04-2012, 05:24 AM #6

Registered

Registered

- Join Date

- Feb 2005

- Posts

- 234

-

04-04-2012, 05:44 AM #7

Flies Fast

Flies Fast

- Join Date

- Dec 2008

- Posts

- 3122

-

04-04-2012, 06:21 AM #8

Registered

Registered

- Join Date

- Feb 2005

- Posts

- 234

-

04-04-2012, 07:00 AM #9

-

04-04-2012, 03:43 PM #10

Registered

Registered

- Join Date

- Dec 2008

- Posts

- 717

-

04-04-2012, 04:41 PM #11

Registered

Registered

- Join Date

- Feb 2005

- Posts

- 234

Yeah... Make fun of my 2nd language........

Thanks for your help

-

04-04-2012, 05:08 PM #12

Registered

Registered

- Join Date

- Dec 2008

- Posts

- 717

Personally, I wasn't making fun of your language...

But if you meant Program or Programmer...those are 2 entirely different things. I assume you did mean program as you are the programmer...which in this case gave us a chuckle.

Tx has a valid point in that many come here and don't have the first clue as to the basics so often times help falls on deaf ears.

I think we answered your question though.:wee:Tim

-

04-09-2012, 08:02 AM #13

Gold Member

Gold Member

- Join Date

- Aug 2011

- Posts

- 2517

if its an enclosed cylinder it'll be very difficult to machine by a noob because access to the inner cavity is only available via the front hole. that kind of thing is better fabricated from separate pieces, welded then machined on the external faces and large hole to true it up. alternatively its a pretty easy lathe turning/boring job but finding an internal grooving tool to machine the square shoulder to depth might be an issue. it depends entirely on what it does and what goes inside it.....

-

04-09-2012, 01:06 PM #14

Registered

Registered

- Join Date

- Feb 2005

- Posts

- 234

Actually it is not a cylinder that I'm working on.

Can not use lathe because of the shape.

What I need to know is how MC can do this inner hole mill.

I can not find any sample tutorial on video or web to get me the idea.

I have not got time to try the "helix" cut yet, just what expert here suggest me.

-

04-09-2012, 06:39 PM #15

This is about as simple as I can make it for you:

-

04-10-2012, 01:38 AM #16

Registered

Registered

- Join Date

- Feb 2005

- Posts

- 234

Similar Threads

-

I need a very “small part” part catcher

By Vern Smith in forum Haas LathesReplies: 21Last Post: 08-25-2010, 01:55 AM -

Newb ? - CAD Part interference & mating part dims

By pabmartin in forum Mechanical Calculations/Engineering DesignReplies: 3Last Post: 11-06-2009, 07:18 AM -

sheetmetal part? flatten a rolled part?

By Rich05 in forum SolidworksReplies: 1Last Post: 08-13-2009, 04:22 AM -

Verify Cut part to Design part.

By CaseyCAM in forum NCPlot G-Code editor / backplotterReplies: 0Last Post: 11-02-2008, 03:22 AM -

Part holding and milling 3D part on 2.5D Mill?

By john_t_h in forum MetalWork DiscussionReplies: 6Last Post: 03-15-2008, 12:35 PM

Reply With Quote

Reply With Quote