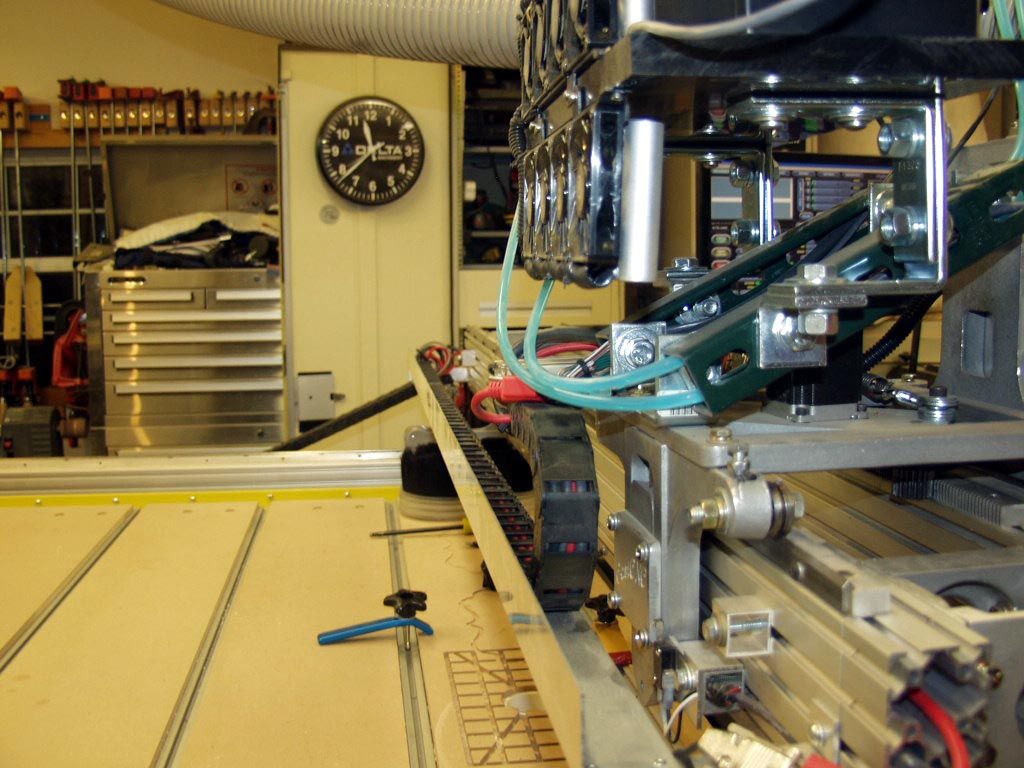

I built a 52X62X8 CastCNC Joes 4X4 Hybrid R&P with welded base, vrail, and 2.2kw water cooled chinese electrospindle with Hitachi VFD.

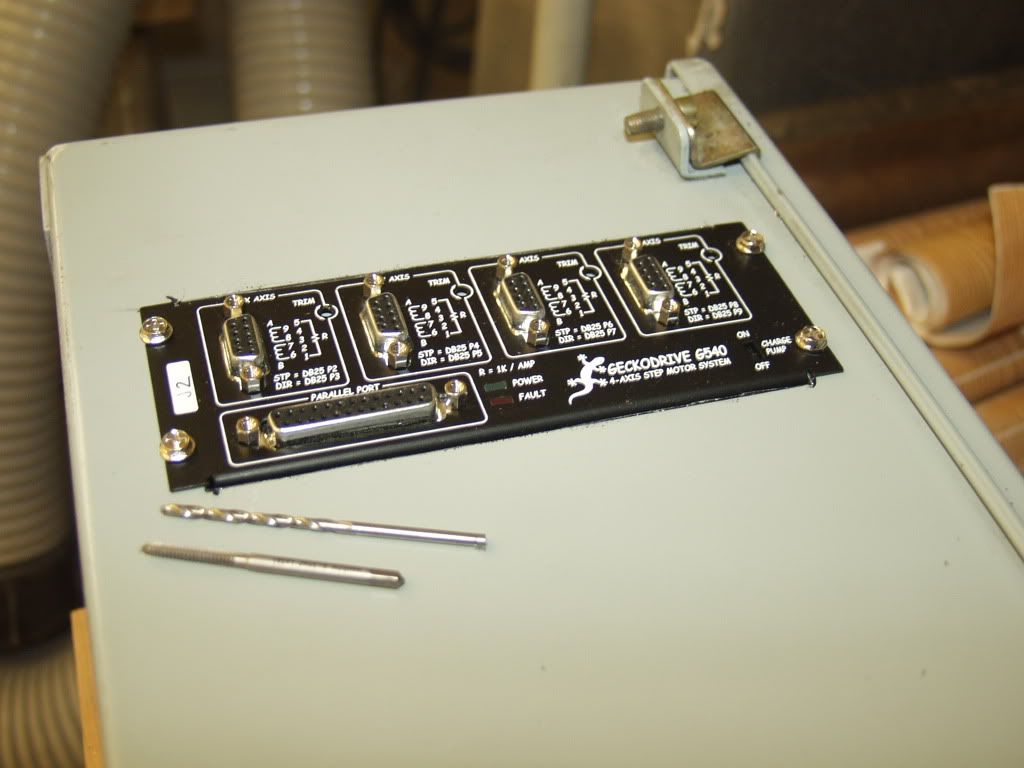

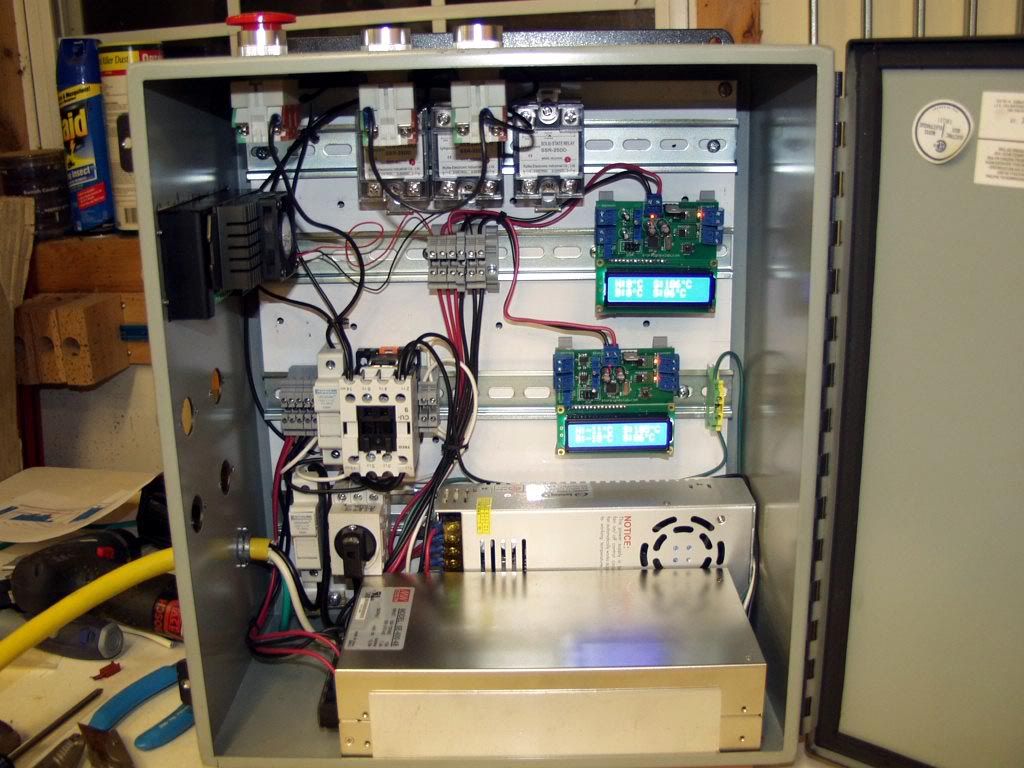

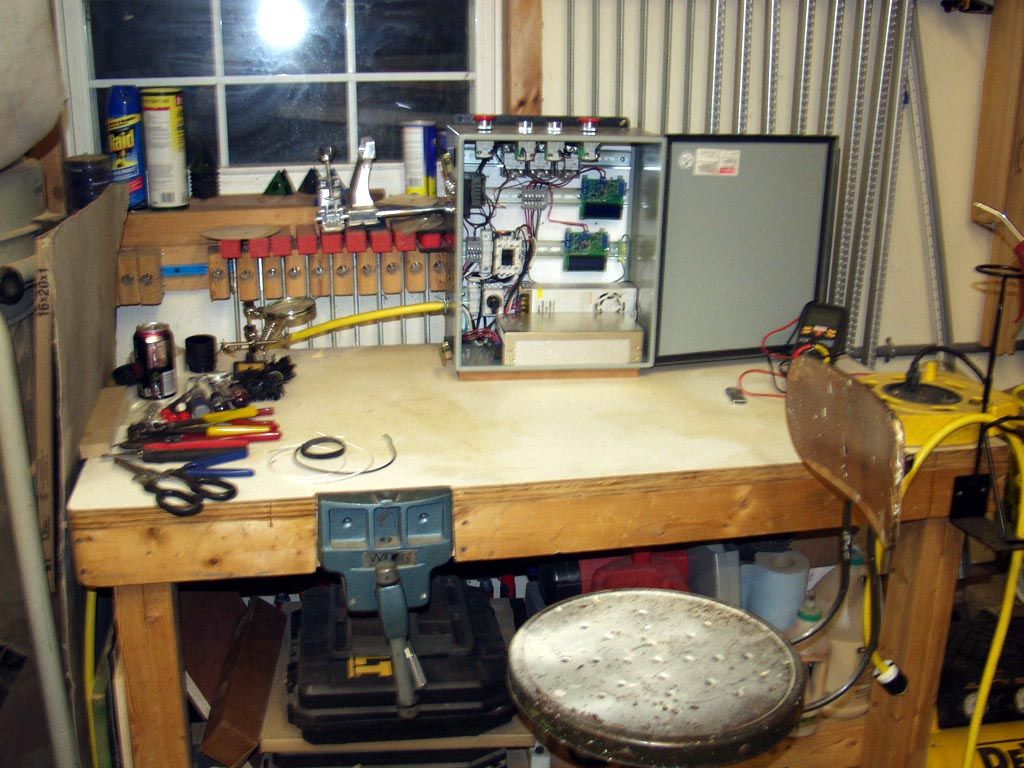

Now I am attempting to bolt on a QU-BD MBE dual extruder. I will be adding another G540 to my existing machine. Plan to use a 8"X8" heated bed and Nuri's GNEXLabs GECS2TC1 and GECS2TS1 boards to control the temp monitoring and DC DC relays to the 12VDC to power them. Everything will be DIN mounted in a 16X14X8 Hoffamn steel enclosure..

OK, had a little shop time today.

Some parts:

Dug out some DIN components I had too.

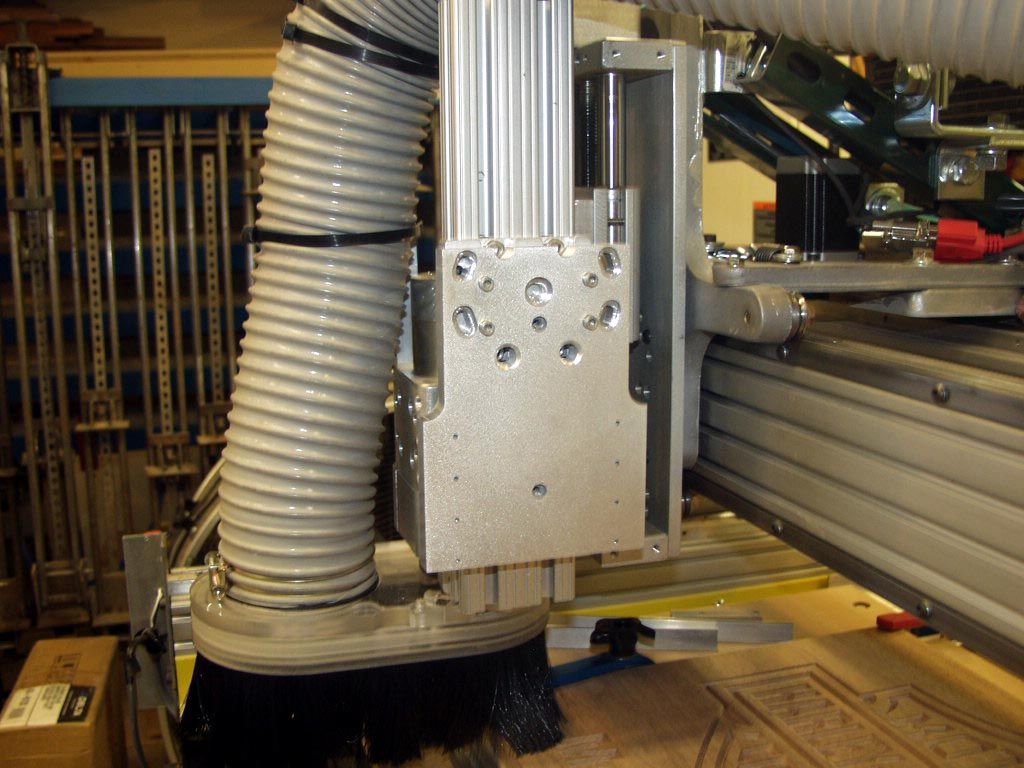

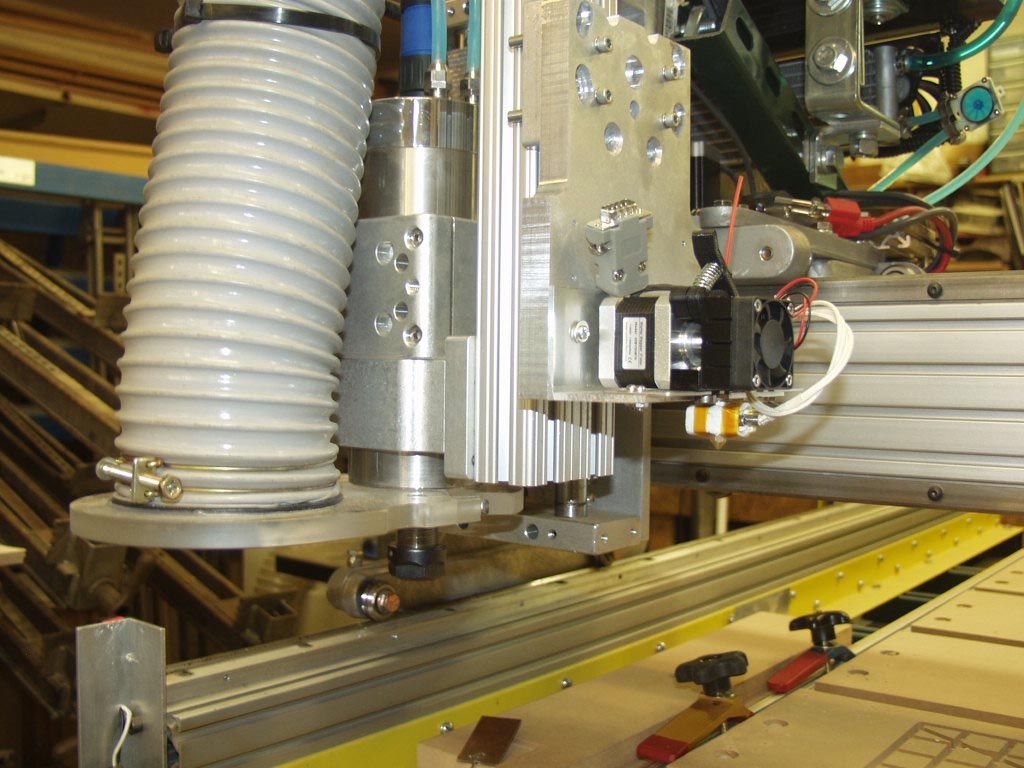

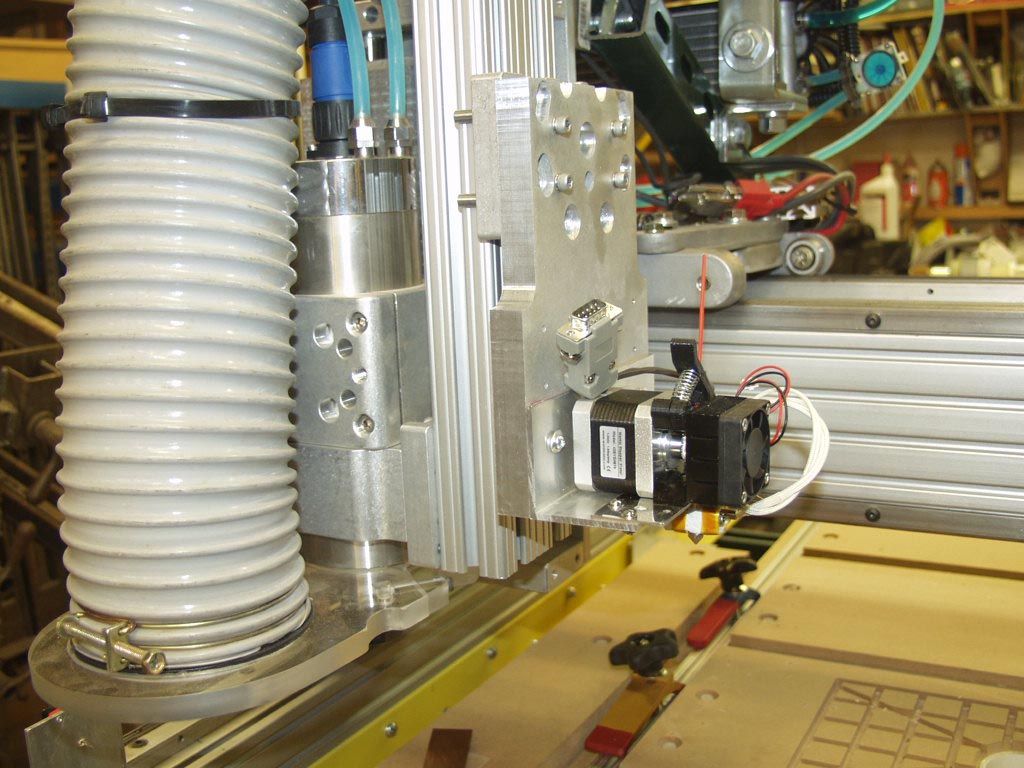

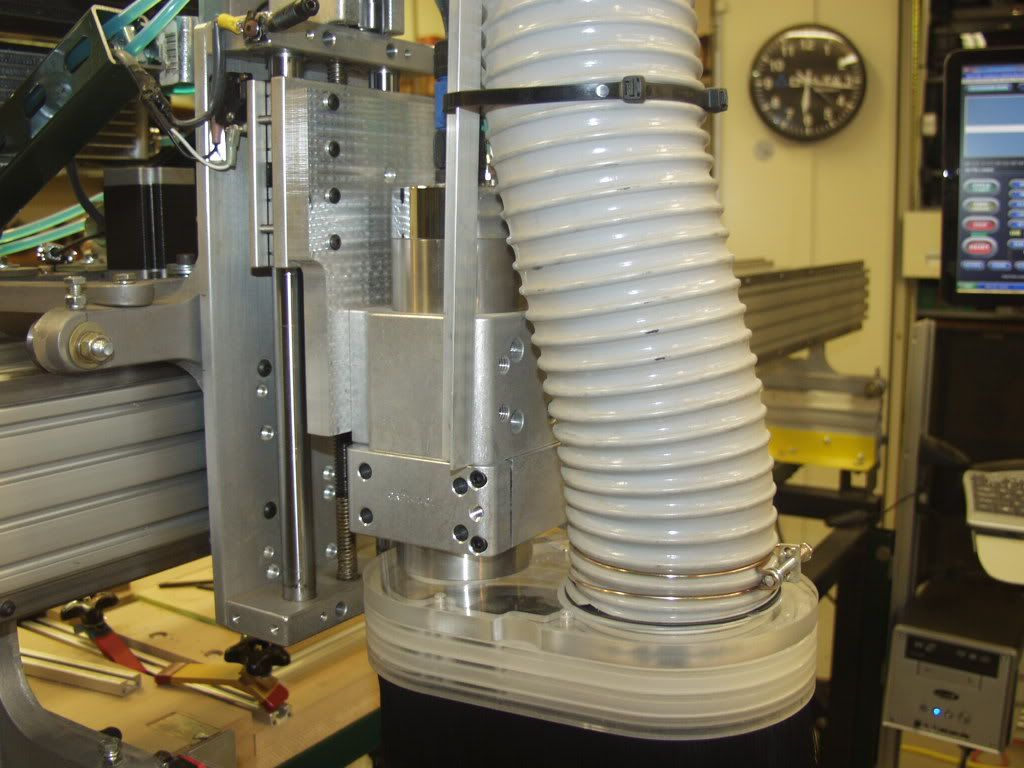

Here is the Z mount, plates, and 1530 mounted. This will get a Drop plate and the eventual extruder mount.

I cut some DIN rail and mounted it. I also figured out my PS arrangement. Made sure fans and most vents were open.

Next up I will cut the hole for the G540 and some connectors.

Results 1 to 20 of 22

-

11-19-2012, 08:00 AM #1

Registered

Registered

- Join Date

- Dec 2005

- Posts

- 58

BloomingtonMike's 3D Extruder Mod for CastCNC Joes

Joes 4X4 R&P, CastCNC v2, K2 8" Z, Vrail, and 2.2kw spindle and X200 w/ Modbus

-

11-20-2012, 08:00 AM #2

Registered

Registered

- Join Date

- Dec 2005

- Posts

- 58

An airsaw, drill, tap later here is what I have.

Joes 4X4 R&P, CastCNC v2, K2 8" Z, Vrail, and 2.2kw spindle and X200 w/ Modbus

Joes 4X4 R&P, CastCNC v2, K2 8" Z, Vrail, and 2.2kw spindle and X200 w/ Modbus

-

11-23-2012, 03:02 AM #3

Registered

Registered

- Join Date

- Dec 2005

- Posts

- 58

Drilled out a few more holes, used a Greenlee 7/8 BB Knock Out Die, a rattle can of Rustoleum Hammered Black and BAM. THANK YOU to Andy at Ugracnc for the switches!

Joes 4X4 R&P, CastCNC v2, K2 8" Z, Vrail, and 2.2kw spindle and X200 w/ Modbus

Joes 4X4 R&P, CastCNC v2, K2 8" Z, Vrail, and 2.2kw spindle and X200 w/ Modbus

-

11-23-2012, 09:17 PM #4

Registered

Registered

- Join Date

- Dec 2005

- Posts

- 58

My version of Turkey day. The boards traveled 5767 miles. These are my temp control boards from Nuri at GnexlabStore.

Joes 4X4 R&P, CastCNC v2, K2 8" Z, Vrail, and 2.2kw spindle and X200 w/ Modbus

Joes 4X4 R&P, CastCNC v2, K2 8" Z, Vrail, and 2.2kw spindle and X200 w/ Modbus

-

11-24-2012, 07:41 AM #5

Registered

Registered

- Join Date

- Dec 2005

- Posts

- 58

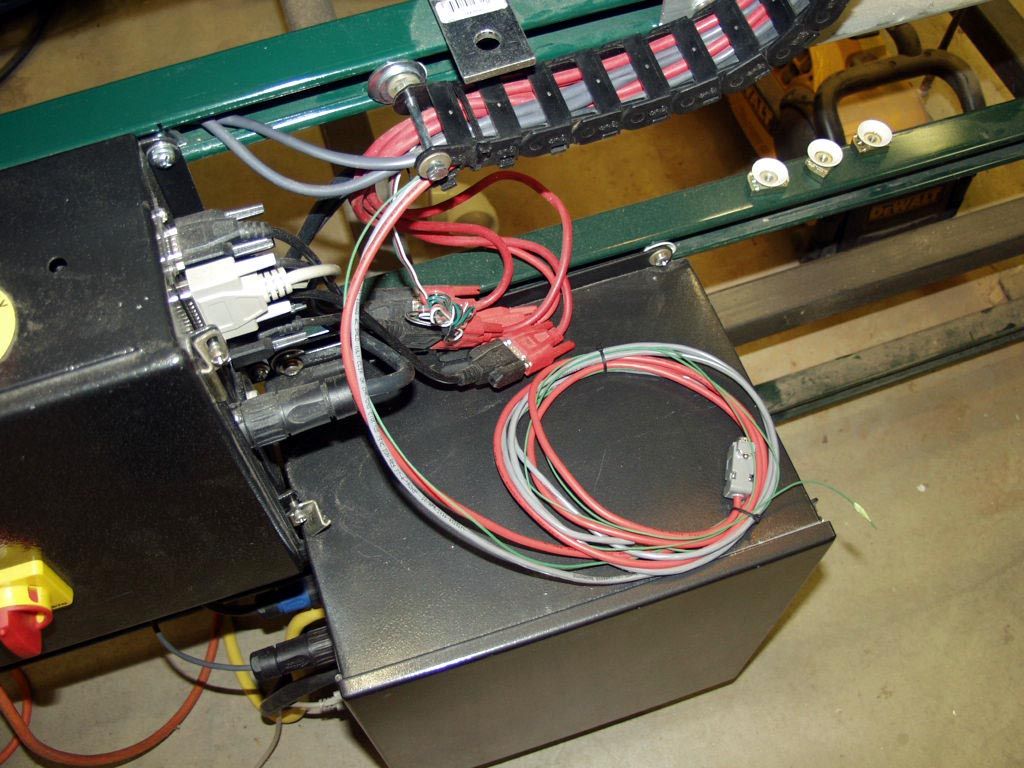

Add in a few feet of wire.....

Joes 4X4 R&P, CastCNC v2, K2 8" Z, Vrail, and 2.2kw spindle and X200 w/ Modbus

Joes 4X4 R&P, CastCNC v2, K2 8" Z, Vrail, and 2.2kw spindle and X200 w/ Modbus

-

11-25-2012, 12:43 PM #6

Registered

Registered

- Join Date

- Nov 2012

- Posts

- 0

Nice

Nice

It looks super clean Mike, I can't wait to stop out soon and check her out!

-

11-30-2012, 06:54 AM #7

Registered

Registered

- Join Date

- Dec 2005

- Posts

- 58

Moving a bit slower. Started a new position at work and it is kind of draining my energy.

Extruders are here.

Ultimachine 1.75PLA filament is here.

Harry's drop plate arrived today.

I have 33' thermocouplers coming from Minnesota.

I have another thermister PID replacement board on its way from Turkey (I have a bad LED on my 1st one) along with some of nuri's thermocouplers.

Ordered a new MBE QU-BD extruder mount plate (makergear one) that will be easier to adapt to my CNC I think and also ordered some other extra accessories (tape, shrink, insulation, etc ane the new nozzles they have for sale.

Its coming together.Joes 4X4 R&P, CastCNC v2, K2 8" Z, Vrail, and 2.2kw spindle and X200 w/ Modbus

-

12-01-2012, 06:30 AM #8

Gold Member

Gold Member

- Join Date

- Aug 2004

- Posts

- 2849

Mike,

I see that you found a good use for your SawStop.

Nice build.

Paul

-

12-02-2012, 06:37 AM #9

Registered

Registered

- Join Date

- Dec 2005

- Posts

- 58

It makes one hell of a $4K bench for sure

Tonight I solder up a Homann G540 resistor/POT DB9 connectors to the G540 end of one of Ahrens 20' cncrouterpart cables (afetr cutting off his connector). His cables are nice but the 3.5K ohm resistor was not right for the 1.2amp nema 17 motor on my extruder. I hooked that connector up to my multimeter and dialed in 1.2K ohms of resistance. Then put it in a DB9 shell.

Then I cup soldered up a male DB9 connector to the nema 17 motor and alo put it in a shell.

I hooked both up to my existuing G540 to the Z axis and did a test drive. Worked perfect.

Tomorrow I will hook the 2nd controller up and jog it as a 5th axis or attempt too

The 30' thermocouplers came in today too and I played with them on the gecs2TC1 - work awesome. Tomorrow they will get connected to the amphenol ecomate connectors.Joes 4X4 R&P, CastCNC v2, K2 8" Z, Vrail, and 2.2kw spindle and X200 w/ Modbus

-

12-02-2012, 03:01 PM #10

Following this one closely Mike... I have similar desire for a 3D printer with a standard Joe CNC.

-

12-03-2012, 05:24 PM #11

Registered

Registered

- Join Date

- Dec 2005

- Posts

- 58

Don't forget to get the Vectric 2012 Advent Calendar's free files if you can use them. I try and get them all each year. Happy Holidays. Be safe in your shop.

Joes 4X4 R&P, CastCNC v2, K2 8" Z, Vrail, and 2.2kw spindle and X200 w/ Modbus

-

12-04-2012, 06:30 AM #12

Registered

Registered

- Join Date

- Dec 2005

- Posts

- 58

Drop plate done. I can now adjust it up and down through foru access holes. Easy enough to move it up out of the way when not in use.

Nema 17 DB9 solderd up and one of Ahrens cncrp cables with the end changed for a 1.2K resistor.

Harley sign for a customer

Clean up!

Joes 4X4 R&P, CastCNC v2, K2 8" Z, Vrail, and 2.2kw spindle and X200 w/ Modbus

Joes 4X4 R&P, CastCNC v2, K2 8" Z, Vrail, and 2.2kw spindle and X200 w/ Modbus

-

12-04-2012, 07:17 AM #13

Registered

Registered

- Join Date

- Dec 2005

- Posts

- 58

Also made a video tonight of getting the two G540s working in Mach. Also shows movement of 4 axis on one computer through two parallel ports.

[ame=http://www.youtube.com/watch?v=DlRwirsfRVc]Configuring a second Gecko G540 in Mach - YouTube[/ame]Joes 4X4 R&P, CastCNC v2, K2 8" Z, Vrail, and 2.2kw spindle and X200 w/ Modbus

-

12-06-2012, 05:06 AM #14

Gold Member

Gold Member

- Join Date

- Aug 2004

- Posts

- 2849

Mike,

Sawstop looks better.

What are you using for a "heated bed" are you using the gecs2ts1 to control the temp. of the "heated bed"?

My QU-BD dual extruder is on it's way.

Paul

-

12-06-2012, 01:29 PM #15

Registered

Registered

- Join Date

- Dec 2005

- Posts

- 58

I bought QU-BD's 200X200 silicon heated bed for $20. I thought that was pretty cheap. And yes that is what I bought the gesc2ts1 for. If you order a heated bed, Id buy some more of their heat shrink, kapton tape, basically a bit of all the assembly accessories and maybe the makergear plate while you are at it. It will to combine shipping and the dual extruder comes with barely enough to assemble the hot end - I dropped the shrink while assembling the thermister and almost could not find it (not that you need the thermister if you change to a thermocoupler).

Just to be clear - the gecs2ts1 and gecs2tc1 are kinda limited to about 5 amps so I am using them to just close coils on solid state relays - 12V coil and 12V line solid state relays bought on ebay. Link to Solid State Relay - They take a few days to get here. They are rated at 25amps ea so they will pass the high amp side of the circuit. Nuri does sell his power booster now but I am thinking a good old relay is what I want in this config.

Also spell out you want the makergear plate - they sent me the wrong one and I ended up with two of the universal plates which are soooo narrow that it is almost useless. They are correcting it but I may just cnc my own alum plate.

Also there is a guy in Minnessota on ebay selling 10M thermocouplers that will go through my energy chain for all my access to my controller on the side of my 4X4 machine. Check them out if you are adding this setup to a larger CNC machine.

Now the Harley signs I posted on Facebook are selling like crazy so I will need to get those jobs done before Christmas. Oh well it pays for most of this upgrade LOL.Joes 4X4 R&P, CastCNC v2, K2 8" Z, Vrail, and 2.2kw spindle and X200 w/ Modbus

-

12-07-2012, 06:11 AM #16

Gold Member

Gold Member

- Join Date

- Aug 2004

- Posts

- 2849

The dual extruder, heated bed, kapton tape and insulation have been shipped. I asked for the makerbot mount for the extruder...we'll see what we get.

I just saw the LulzBot...that looks like a nice system...oh well.

I'll just add the extruder to my X3 and see how that works out. I'll order the gecs2ts1 and the gecs2tc1 tomorrow and the Gecko 540 and power supplies.

Mike, where did you source the power supplies from?

Paul

-

12-08-2012, 06:31 AM #17

Registered

Registered

- Join Date

- Dec 2005

- Posts

- 58

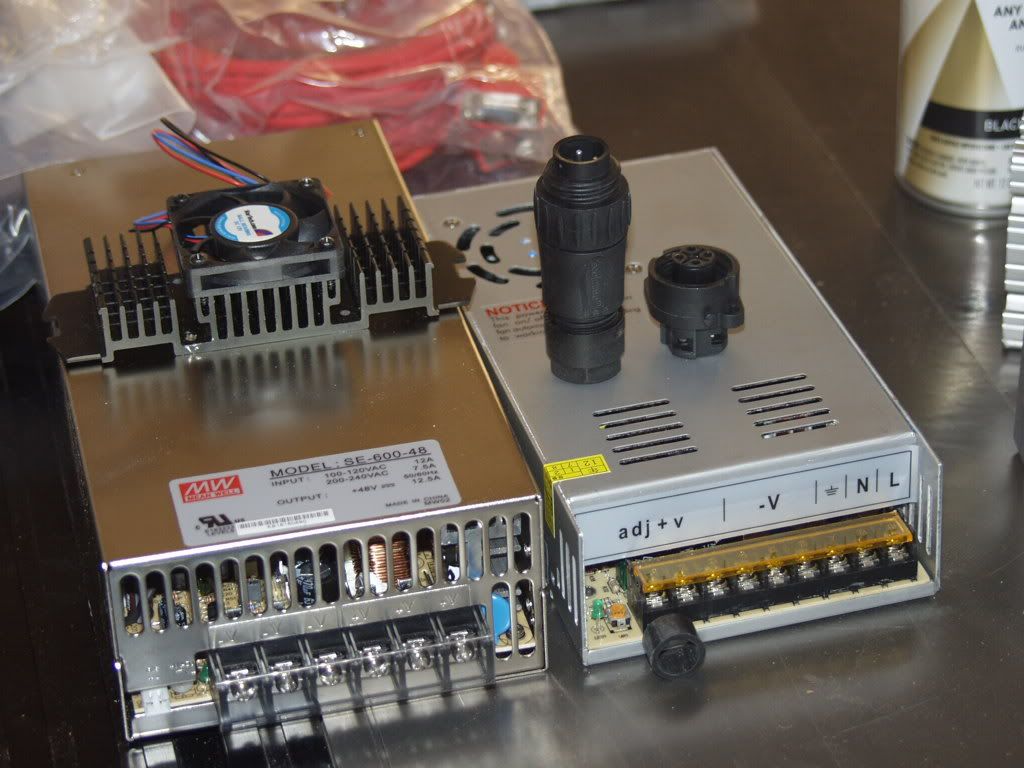

I had the 48V 12.5amp powersupply for the gecko already - it came from ahren at cnc routerparts. It is an actual MeanWell power supply - pretty nice for an import but over $112. Pretty much overkill for sure.

I really need to get the pololu 4988 solution working to save folks some serious money if they already have one G540 and are not using any outputs. It would save you a G540 purchase and would require a small Power supply - in fact the 12V below could drive the pololu too I get.

I bought the 12V 30amp power supply from ebay for $30 shipped LOL - it is a cheap copy of the MeanWell also an import.

Power Supply linkJoes 4X4 R&P, CastCNC v2, K2 8" Z, Vrail, and 2.2kw spindle and X200 w/ Modbus

-

12-24-2012, 04:28 PM #18

Registered

Registered

- Join Date

- Dec 2005

- Posts

- 58

So got the signs done and shipped. Went back to the printer.

Also decided to build a standalone printer as well as the add on. Choose an Ord Bot Hadron kit and got that ordered. Also will drive it with a RAMPS 1.4 controller, Pololu motor controls, an Xteeg digital display and SD reader when they ship (backed the Kickstart), and 12V 30amp power supply. Will not require a PC.

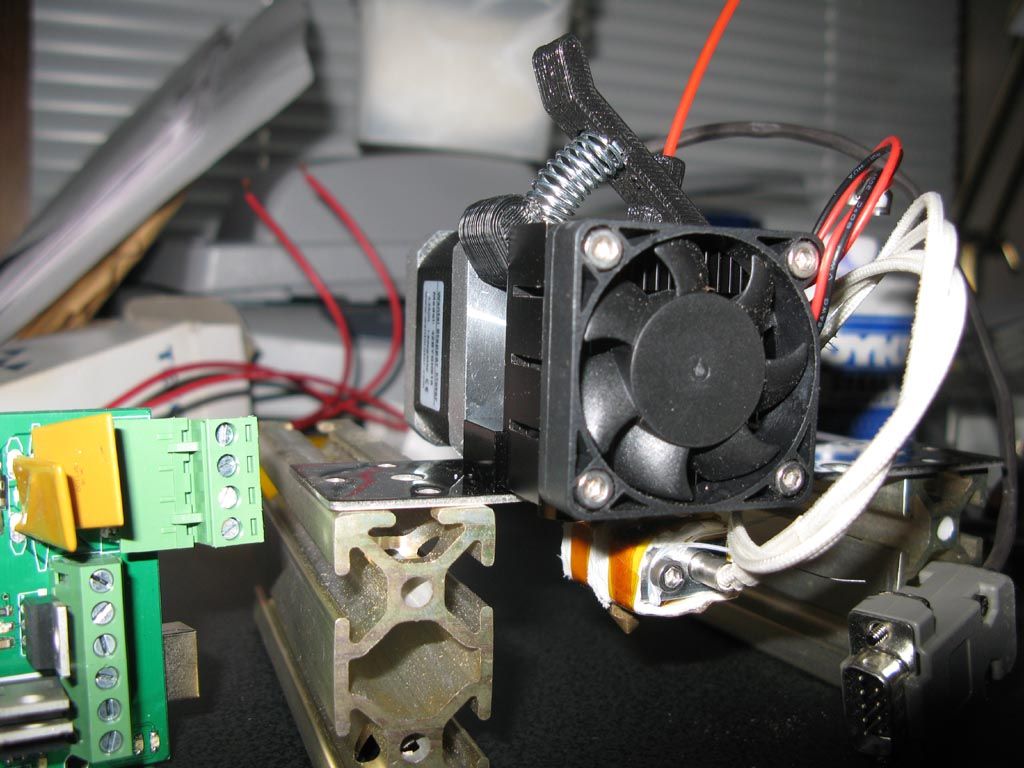

Here are the latest pictures. Got one extruder assembled. I changed to a Maker Bot Gear and the ball bearing Minimalistic MK7 Replacement tensioner for the filament. Hot end has a heater cartridge and a Thermister for now.

Also worked on the RAMPS 1.4 (Chinese version) and Pololu A4988s and got those all soldered up. I loaded Marlin firmware on the RAMPS. It is a shield for my Arduino Mega 2560.

Joes 4X4 R&P, CastCNC v2, K2 8" Z, Vrail, and 2.2kw spindle and X200 w/ Modbus

Joes 4X4 R&P, CastCNC v2, K2 8" Z, Vrail, and 2.2kw spindle and X200 w/ Modbus

-

12-25-2012, 08:42 AM #19

Registered

Registered

- Join Date

- Dec 2005

- Posts

- 58

Merry Christmas!

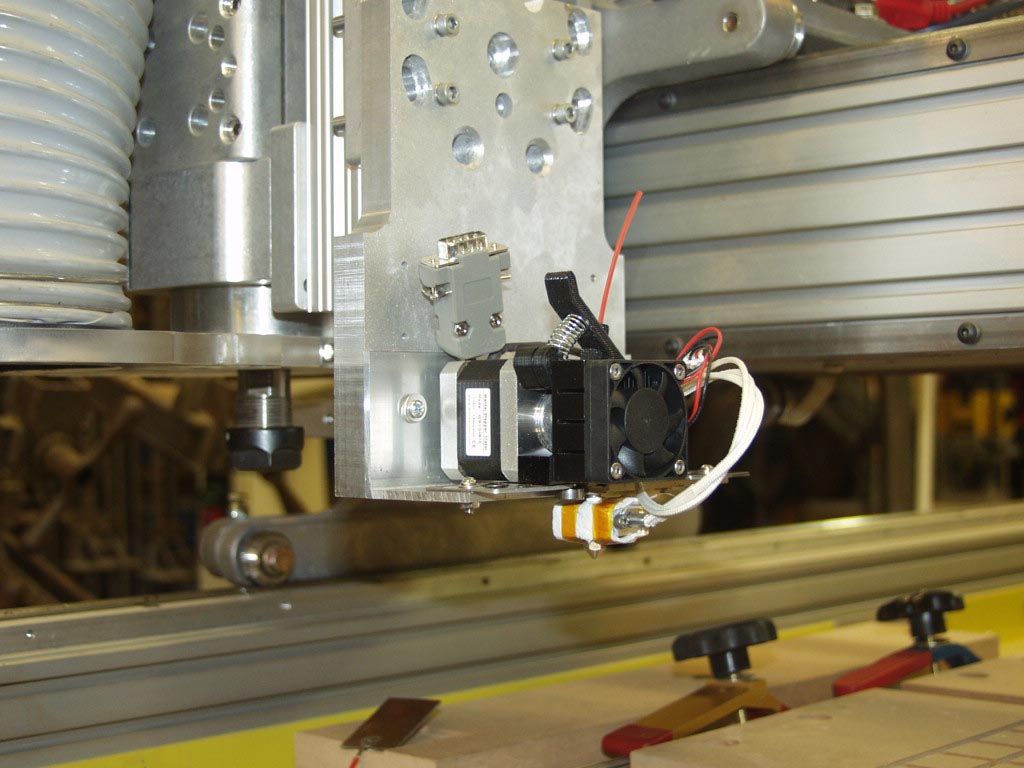

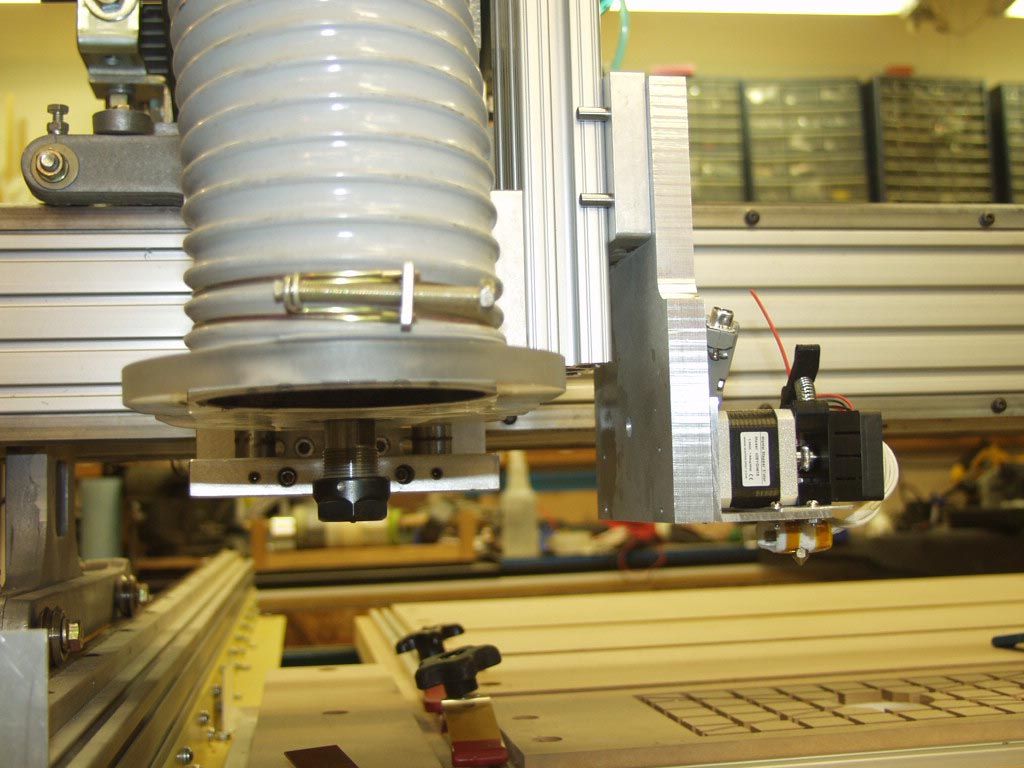

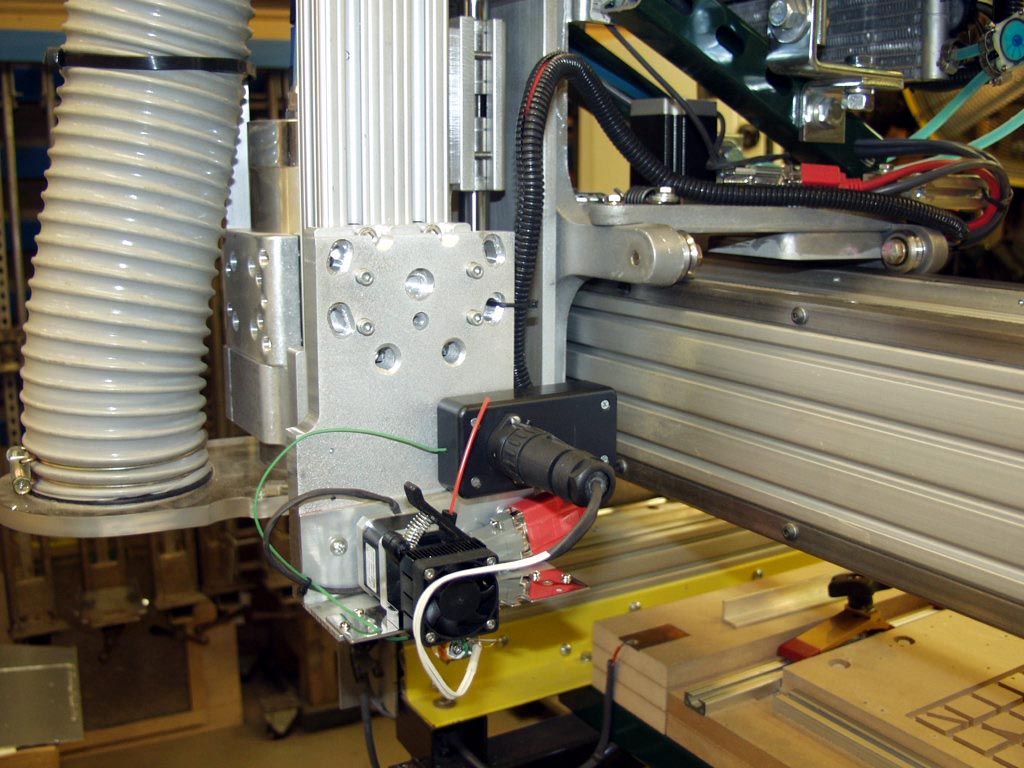

Got the extruder mounting bracket built out of some 1/8" thick 2" Angle Alum.

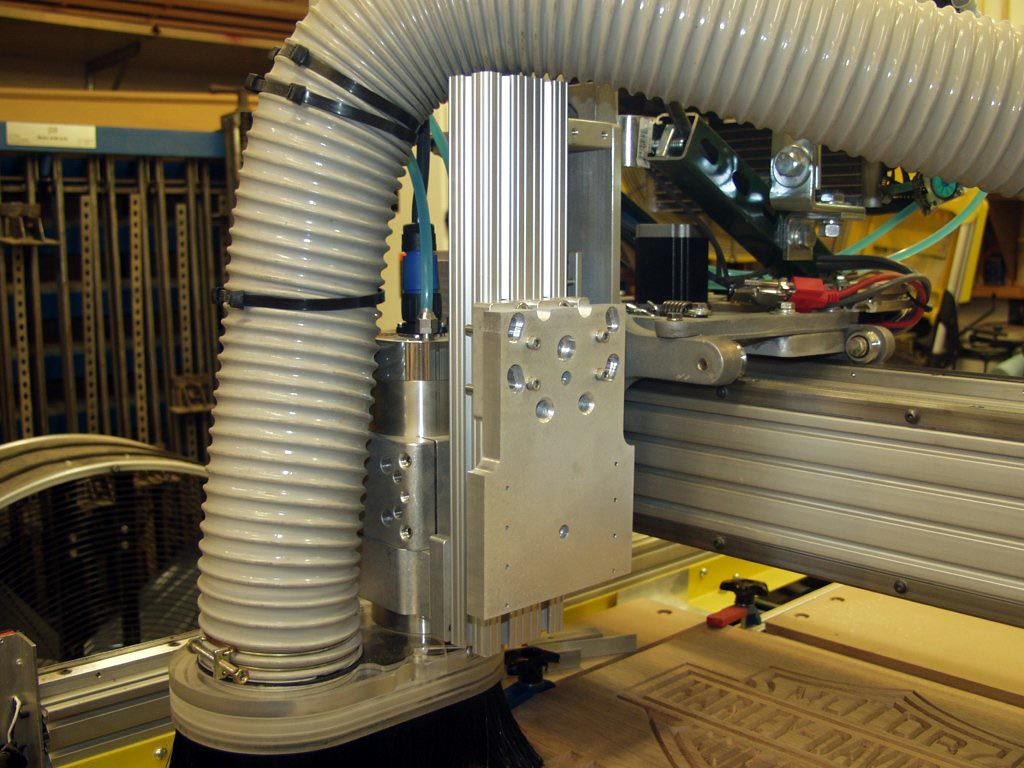

Here it is mounted - Lowered and Raised.

Joes 4X4 R&P, CastCNC v2, K2 8" Z, Vrail, and 2.2kw spindle and X200 w/ Modbus

Joes 4X4 R&P, CastCNC v2, K2 8" Z, Vrail, and 2.2kw spindle and X200 w/ Modbus

-

12-26-2012, 08:15 AM #20

Registered

Registered

- Join Date

- Dec 2005

- Posts

- 58

Got the top half of the extruder wired up. Made it pluggable to make it easy to remove. Wired a 4 conductor cable, a thermocoupler, and the 9 pin serial cable to drive the stepper motor. Next up - wire the controller for the wires coming out of the E chain. Won't be long before I see what this extruder can do.

Joes 4X4 R&P, CastCNC v2, K2 8" Z, Vrail, and 2.2kw spindle and X200 w/ Modbus

Joes 4X4 R&P, CastCNC v2, K2 8" Z, Vrail, and 2.2kw spindle and X200 w/ Modbus

Similar Threads

-

Extruder

By SPEEDRE in forum 3D Printer / 3D Scanner DiscussionReplies: 31Last Post: 02-19-2013, 04:32 PM -

Extruder/Hotend for $34 (Kickstarter)

By Vulcan R&D in forum 3D Printer / 3D Scanner DiscussionReplies: 1Last Post: 06-12-2012, 07:55 AM -

BloomingtonMikie's CastCNC machine (pic heavy)

By BloomingtonMike in forum DIY CNC Router Table MachinesReplies: 4Last Post: 04-01-2011, 09:35 AM -

CastCNC v2

By CastCNC in forum Joes CNC Model 2006Replies: 0Last Post: 03-09-2011, 07:46 AM -

CastCNC - Aluminum Top Out kit for Joes 4x4 Hybrid

By CastCNC in forum News AnnouncementsReplies: 54Last Post: 08-12-2010, 03:31 PM

Reply With Quote

Reply With Quote