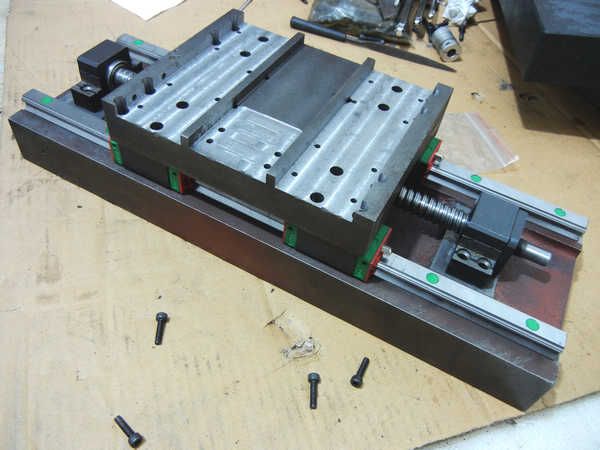

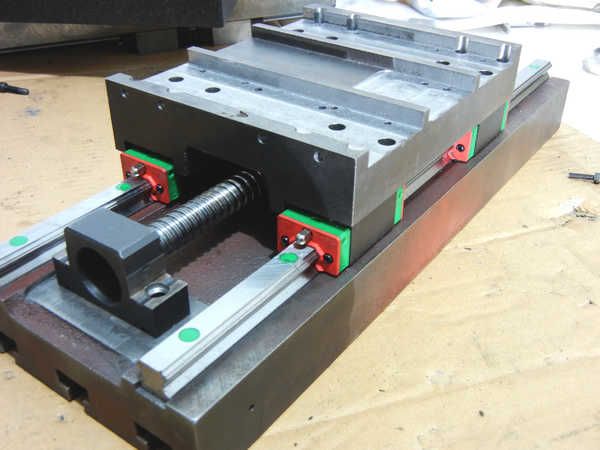

Hi guys, I didn't work much these two days because fo CNY issue. But I did try to assemble the worktable and saddle part together. This is some simple work just if all parts were machined as the designed sizes. So I did just some screwing works and all of the screws just fit in well. The ballscrew and the mounts seems perfect match also. so I guess I will not get much trouble when formal installation.

I use some high strength bolts of 12.9 class here. We alway use such class bolts on machines to make sure high rigidity under heavy load works. It's a small aspects but if don't do the small things right, no matter how good the "big" parts are, the total structure will just be weak. That's the truth of short plat theory.

Results 1 to 20 of 3662

Hybrid View

-

02-08-2013, 07:04 PM #1

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

-

02-08-2013, 08:30 PM #2

Registered

Registered

- Join Date

- Jul 2009

- Posts

- 690

That's a great thing to do. I get most of my mechanical components from China and one thing I've noticed is that there's a tendency to go cheap with fasteners on components such as SBR rails and BK/FK blocks, which means I usually have to replace stripped bolts that weren't originally holding well (for SBR rails this is especially bad), and even if they are holding fine I need to replace them anyway so I can actually tighten them without stripping the hex head. Since I started using 12.9 I've not stripped any more bolts, very hard stuff! :cheers:

BTW, nice build!http://www.build.cl

-

02-08-2013, 09:28 PM #3

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 441

Hi Walky, Thank you for your input. I think we touched some weak points usually happend on some China products. Yes, I can understand totally what you are saying. many products will just announce the "big" part of the components but ignore the small parts not easy to see. like bolts, yes. usually very cheap ones even not standard 8.8 class. And maybe also the bearings in BK/FK units.

I don't know if you have disassembled some BK units and checked the bearings inside. I can tell you here many bearings are from no brand small bearing factories. even not P5 class, not good steel material, no any brand mark on the bearings or fake mark. That's the lowest end products and just cheap. I would like to use the real bearings of HRB--the best brand in China; or NSK from JP. They are just some best cost performance for my products.

As to bolts, I always use 12.9 class ones from EG brand----one of the biggest bolt supplier in the world. good quality. That's totally fool to save maybe 1$ on such small parts.

Since we touched something Made in China now, I want to say I want to do something beyond the cheap way. but the most cost performance way. I will not choose the most expensive parts, but must be the well known quality parts or quality parts we approved with reasonable cost. I think it's the way to manufacture good machines together with good cost control.

I'm trying my way with Good idea&design, Good parts even smallest one, Good manufacture and Good service. And that's why I show every process of building mine machine here.

I'd like to talk on every details including the smallest one, totally open my works and I think this is the way to be approved.

Thank you again. Welcome more comments~ :cheers:www.skyfirecnc.com

Email: [email protected]; Skype: skyfirecnc

Similar Threads

-

Show us your machine stands

By OHLEMANNR in forum Benchtop MachinesReplies: 7Last Post: 05-05-2013, 03:19 AM -

a machine design (pics) from beginning to end

By blurrycustoms in forum Vertical Mill, Lathe Project LogReplies: 42Last Post: 04-25-2013, 02:36 AM -

dry build or glue from the beginning?

By Ezra in forum Joes CNC Model 2006Replies: 2Last Post: 10-29-2010, 04:44 AM -

Newcastle: Beginning of build plan

By pippin88 in forum Australia, New Zealand Club HouseReplies: 7Last Post: 09-16-2010, 10:22 AM -

Beginning to build my Z-axis.

By zonk2 in forum DIY CNC Router Table MachinesReplies: 0Last Post: 12-23-2008, 06:17 AM