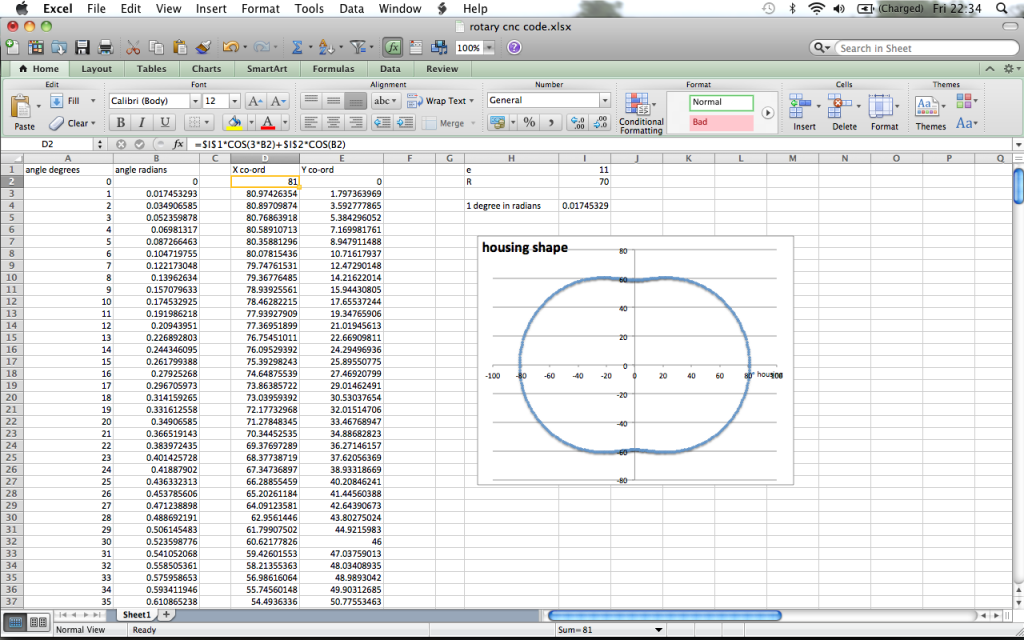

i'm a bit of noob when it comes to excel but have managed to make up a spread sheet to define the shape of the housing for CNC code purposes.

this was done using the formula i found above and the dimensions are basically home made to a shape that looks like it would show best the irregular geometry of the housing.

i took X and Y co-ordinates ranging from 0 degree to 360 degree and fed them into the graph on the sheet

if you have any dimensions or link to other sueful information that you may think is helpful that would be greatly appreciated as was your post already .

yes thats the idea i had but was told to make something that is only a mechanism or linkage to show the motion....

thank you for your input it is greatly appreciated.

Thread: wankel rotary project

Results 1 to 20 of 20

Threaded View

-

01-10-2014, 11:44 PM #4

Registered

Registered

- Join Date

- Oct 2013

- Posts

- 13

Similar Threads

-

Info on Rotary Wankel engines.

By Mach1n1st in forum I.C. EnginesReplies: 4Last Post: 12-31-2014, 03:51 PM -

wankle not Wankel

By Ken McKenzie in forum I.C. EnginesReplies: 11Last Post: 01-17-2012, 07:34 PM -

Need help with rotary table project

By praetor in forum Vertical Mill, Lathe Project LogReplies: 2Last Post: 04-27-2010, 12:58 PM -

My first wankel engine 'bits'!

By itsme in forum I.C. EnginesReplies: 285Last Post: 09-05-2009, 07:46 PM -

Instruction for making a Wankel engine

By Ken McKenzie in forum I.C. EnginesReplies: 159Last Post: 08-07-2006, 08:04 PM

Reply With Quote

Reply With Quote