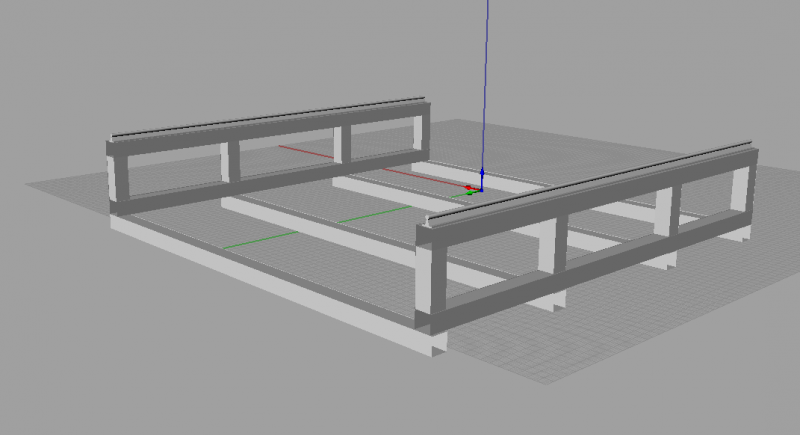

Starting my build thread for my new cnc. 5'x5' frame, should have a useable cutting area of at least 48"x48"x12". Transferring over my spindle and electronics, all new motors, 425oz inch and 5 start acme screws, dual on the gantry drive. Ill update this thread when i get more cad done on it, i have ordered many parts i still have to get more acme rod and some misc. acme drive parts. The sbr rails are 59" long. Hoping to eventually add a 4th axis. Once i get the steel in the next week or so i will post some build pics. Thanks for looking!

Thread: 5'x5' Steel build";

Results 1 to 20 of 34

-

03-09-2014, 05:29 AM #1

Registered

Registered

- Join Date

- Jul 2009

- Posts

- 85

5'x5' Steel build";

-

03-10-2014, 02:47 AM #2

Registered

Registered

- Join Date

- Jul 2009

- Posts

- 85

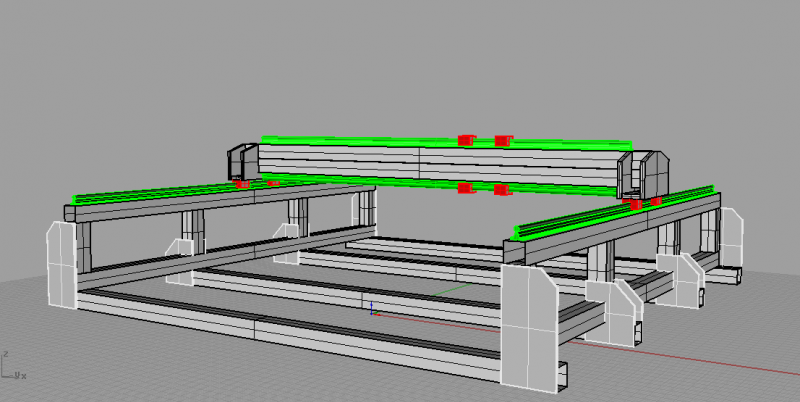

More rendering done, also ordered the remaining acme parts i need, minus the two rails. I am waiting on funds for that. I will be picking up the 2x2 square tubing this week though. It is amazing how fast things add up even when you have most of the parts from the previous machine already. If you have any comments or suggestions lmk! Thanks for looking!

-

03-12-2014, 12:11 AM #3

Registered

Registered

- Join Date

- Jul 2009

- Posts

- 85

No suggestions? Was wondering about them facing the 2" square tube only being 1/8" wall, wondering how much they will have to take off?

-

03-12-2014, 02:22 AM #4

Registered

Registered

- Join Date

- May 2005

- Posts

- 1662

How are the SBR style rails attached to the square tubing ? Tapping the tube isn't much thread engagement.

A better question might be whether the tube will be straighter after facing or if the stresses released will make it worse. Better ask whoever is doing the work.Was wondering about them facing the 2" square tube only being 1/8" wall, wondering how much they will have to take off?Anyone who says "It only goes together one way" has no imagination.

-

03-12-2014, 02:34 AM #5

Registered

Registered

- Join Date

- Jul 2009

- Posts

- 85

Tapping the tube is the only way i can think. Maybe i can up the amount of mounting holes. I have been wondering about welding. Maybe i should bolt together? Maybe someone will chime in with experience.

Sent from my LGMS769 using Tapatalk

-

03-12-2014, 02:24 PM #6

Registered

Registered

- Join Date

- May 2005

- Posts

- 1662

If your rail is the same as mine it's drilled for 5mm bolts. A 5mm bolt has 0.8 mm pitch and the tube is ~3mm thick which is a bit thinner than the common 5mm nut.

Maybe tap a test hole and see what kind of torque you can get on the fastener ?Anyone who says "It only goes together one way" has no imagination.

-

03-14-2014, 11:56 PM #7

Registered

Registered

- Join Date

- Jul 2009

- Posts

- 85

Receive my Rails today they look like they're not very straight, however I feel whenever I bolt them on the steel that they will be straightened out. I bought the steel and aluminum gantry piece and i scored a 4-inch by 6 inch by 6 foot 3/16 inch wall for 40 bucks! I am considering not machining the rail support area on the steel and aluminum because I called the machine shops and they do not have the capacity to do this. Let me know when you guys think.

Sent from my LGMS769 using Tapatalk

-

03-15-2014, 03:10 AM #8

Member

Member

- Join Date

- Jun 2005

- Posts

- 3502

With all the steel and rail supports, put the crown site up! Their weight will straighten them!

www.widgitmaster.com

It's not what you take away, it's what you are left with that counts!

-

03-17-2014, 04:02 AM #9

Registered

Registered

- Join Date

- Jul 2009

- Posts

- 85

-

03-29-2014, 12:52 PM #10

Registered

Registered

- Join Date

- Jul 2009

- Posts

- 85

Re: 5'x5' Steel build";

Little update, did a test run on the bracket for the end caps/ motor mounting bracket.

-

03-29-2014, 07:44 PM #11

Registered

Registered

- Join Date

- Jul 2009

- Posts

- 85

-

03-31-2014, 02:52 AM #12

Registered

Registered

- Join Date

- Jul 2009

- Posts

- 85

Re: 5'x5' Steel build";

Quickly discovered this design won't work. The screw is just too long for the diameter and has too much flex. Am now considering rotating nut design.

Sent from my LGMS769 using Tapatalk

-

04-05-2014, 03:55 PM #13

Registered

Registered

- Join Date

- Mar 2014

- Posts

- 735

Re: 5'x5' Steel build";

I like your design, The x axis is kept low relative to the z axis. Should be a fairly rigid structure. I'll be curious to know if you can get the steel straight enough. That would be the main reason I would choose 8020 over steel when I build mine. Keep us posted.

Also, it seems you could convert your power transmission over to rack and pinion pretty easily if the rotating nut doesn't work.

Sent from my VS980 4G using Tapatalk

-

04-12-2014, 12:19 AM #14

Registered

Registered

- Join Date

- Jun 2009

- Posts

- 267

Re: 5'x5' Steel build";

Any progress with the rotating nut design? You got me curious!!

-

04-13-2014, 07:35 PM #15

Registered

Registered

- Join Date

- Jul 2009

- Posts

- 85

Re: 5'x5' Steel build";

No progress yet, been working on a car that i am getting ready to sell. Also, my machine computer took a dump so i had to get another one and get it going for the time being, cant be without a functioning CNC!

I was waiting on a design for the rotating nut to move forward, but i think i can at least finish the frame and get it square/bolted together and then worry about the power transmission now that i am taking a different approach than originally planned for.

-

09-06-2014, 09:50 PM #16

Registered

Registered

- Join Date

- Jul 2009

- Posts

- 85

Re: 5'x5' Steel build";

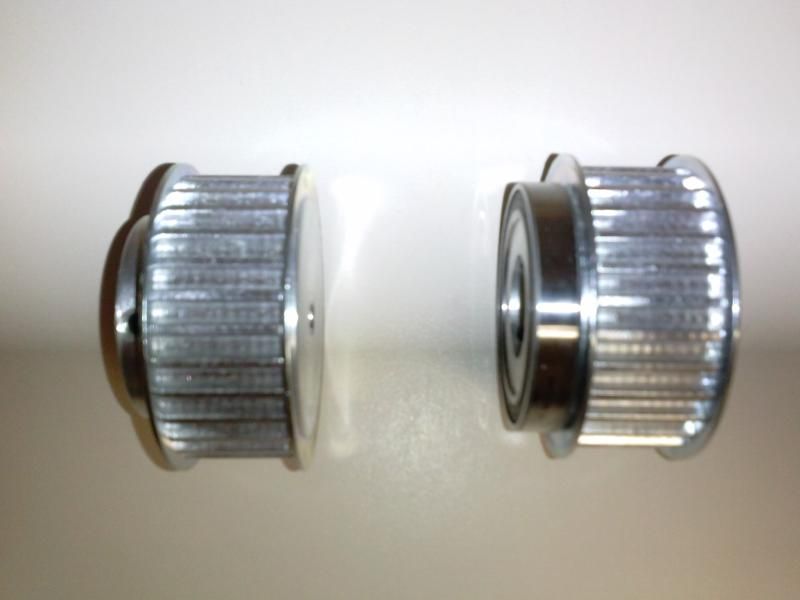

Well, it has been a while. Not gone just have not gotten very far on the machine. Too many other things going on, including the newest addition to my family, my baby girl! Anyways, The last time i was working on this project i realized the 6' acme 5 start screws were too long and had too much flex for the conventional turning the screw. I then decided that it would be more practical to do a rotating nut design. Have looked at a few designs out there, but not really for acme mostly ballscrew. Anyways, i plan on designing some plates and cutting them on my small cnc to get this thing back rolling. Here is what i bought pulley wise, i messed up on the lengths of the timing belts and they are too short, not a big deal they were cheap so ill just order some longer ones. Any suggestions on the design of the mounts? Thanks.

-

09-27-2014, 01:43 PM #17

Registered

Registered

- Join Date

- Jul 2009

- Posts

- 85

-

09-27-2014, 05:29 PM #18

Member

Member

- Join Date

- Feb 2005

- Posts

- 829

Re: 5'x5' Steel build";

I will keep an eye on your rotary nut. Looks like a great way to create a compact low backlash movement system.

-

01-04-2015, 02:46 AM #19

Registered

Registered

- Join Date

- Jul 2009

- Posts

- 85

Re: 5'x5' Steel build";

Build Update:

All things considered i have shrunk the size of the unit down to a 3x3 foot work area. That means i am a little over 4 ft by 4 ft on the frame. Am doing 12" spacing on the sbr trucks and have decided to double up the amount needed to reduce flex. Will also see about adding the additional rails like i had originally planned. I know alot will say it is too much to get aligned and should have used profile rails blah blah.... While i do agree they are better, just simply out of the budget considering i only paid $270 shipped for all the rails and that would get me maybe one axis on the others so i will just improvise and put in more work.

For the updated part i have welded up the frame and painted it flat black real quick not really paying too much detail in the oil base a few runs but who cares.... most will be covered anyways.

Mounted one side of the x axis rail and paid close attention and time when doing it because when i got these rails they were warped considerably simply because of the length and the fact they are coming from china. I have used my precision 2 foot rule to straighten and clamp down as i drilled and tapped each bolt and i am satisfied with the results being horizontal alignment of +/- .0015 and vertical flat of +/- .0015 as well. For my purposes it is the best i will get and am happy with that. I do not think i am too far off anyhow but what does everyone else think of those numbers? Thanks.

Be looking out for more updates as i want to keep a steady work on this.

-

03-28-2015, 06:07 PM #20

Registered

Registered

- Join Date

- Jul 2009

- Posts

- 85

Re: 5'x5' Steel build";

Well its been a while but here is another update.

After getting the first sbr rail on i started to regret the chinese rails on this machine so i splurged on the thk ssr15's. I think it is a good decision.

I am still waiting on funds to buy the 1610 ballscrews. That will set me back another 500 Anyways ill keep this thread updated since i will be moving forward at this point.

Similar Threads

-

First build "Steel Gantry moving table"

By charlieslasher in forum DIY CNC Router Table MachinesReplies: 33Last Post: 04-11-2017, 03:50 PM -

New steel Build 36" 48"

By Chris Zenda in forum Open Source CNC Machine DesignsReplies: 8Last Post: 08-11-2015, 02:01 PM -

Boring a 1-3/8" hole on a 5/8" thick 3"x3" cold rolled steel bar

By dalianharley in forum Tormach Personal CNC MillReplies: 11Last Post: 05-14-2014, 02:49 AM -

Some progress on my 30"x30" steel build.

By Nipels in forum DIY CNC Router Table MachinesReplies: 31Last Post: 09-13-2013, 06:54 AM -

Crazy Canadian 1st build 34" x 60" steel

By archer3d in forum CNC Wood Router Project LogReplies: 31Last Post: 06-23-2010, 04:28 PM

Reply With Quote

Reply With Quote