Nice work, nice planning.

Thread: E/G CNC Mill

Results 61 to 70 of 70

-

08-12-2012, 01:57 PM #61

Registered

Registered

- Join Date

- Mar 2004

- Posts

- 1306

Regards,

Mark

-

08-12-2012, 05:39 PM #62

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 43

Thanks guys

I'm relying on the positive pressure in the spindle housing to keep the bearings clean. I used cheap AC bearings from VXB.

Back to the pictures.

Had a company make some TTS blanks for drills and stuff. Did the "grooving" myself with a special tool I made. I have no pictures of it tho.

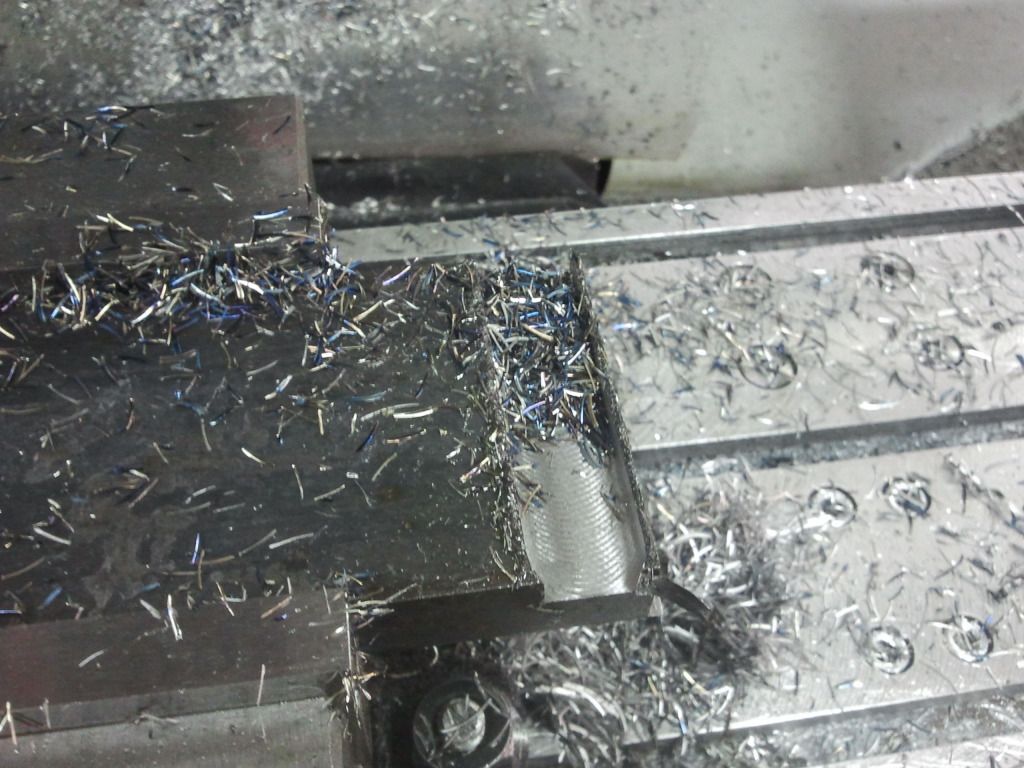

A light test cut in alu

-

08-12-2012, 05:44 PM #63

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 43

I added a counter weight to the Z axis, and what a difference! 7m/min was no problem

[ame=http://www.youtube.com/watch?v=J08mTklEYFg]Counterbalance for the Z axis - YouTube[/ame]

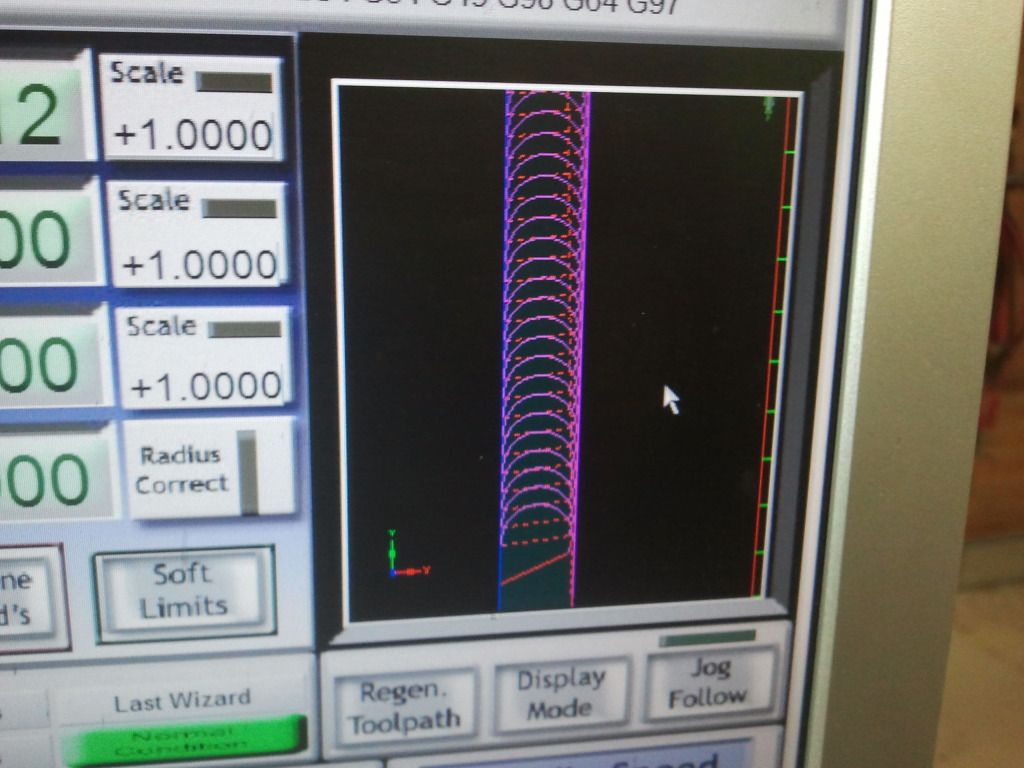

Then I tried some steel

5mm deep

1mm stepover

5000rpm

1200mm/min

[ame=http://www.youtube.com/watch?v=n7bzBHEOpAg]CamBam trochoidal testing - YouTube[/ame]

A note: At this time I was still using the Mk2 taper spindle.

-

08-12-2012, 05:51 PM #64

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 43

Old spindle vs the new

The mounting hole for the spindle was too small..

I'm cnc converting the little lathe (seen in one of the pictures) at the moment. Might start a thread on that too.

Btw, we're getting close to present status on the mill now.

-

01-07-2013, 03:28 PM #65

Member

Member

- Join Date

- Jun 2010

- Posts

- 1422

Love the build. That R8 spindle you made is VERY impressive.

-

06-13-2013, 03:51 PM #66

Registered

Registered

- Join Date

- Jun 2013

- Posts

- 3

hi

this is good working

thanks for your tried

-

09-02-2014, 10:10 PM #67

Junior Member

Junior Member

- Join Date

- May 2012

- Posts

- 67

Re: E/G CNC Mill

thewho,

Time to see some new progress!

Would you be able to give us an estimate of what you have into ($) building this? Many of us really like your work and want to know if something like this is within our personal budgets.

Thank you,

Phil

-

09-03-2014, 09:28 PM #68

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 43

Re: E/G CNC Mill

I can't remember how much I've spent building this machine. But even if I did I don't think it would help people.

It all depends on what machines and knowledge you have access to. Most of the parts is stuff I've collected "in case i need it" over years.

The parts that i had to buy was:

-Motor drivers

-Linear rails (used & very cheap)

-Ballscrews

-1 stepper motor

-Vfd

-A few steel pieces, column and table for ex.

The rest is stuff I already had. Got most parts for free as I'm an electrician (transformer, motor etc.)

I'm browsing the "vertical mill, lathe project log" section here for inspiration to start modifying my machine I could really use a cnc lathe for the stuff I want to do though..

I could really use a cnc lathe for the stuff I want to do though..

I can't remember if I have a thread on here about my cnc lathe project. I've run in to some problems so I've not done anything on it for a while.

Here's the thread on a Swedish forum that I'm more active on. You can maybe run it trough google translate or you can just look at the pictures.

Daniels CNC svarv //B

-

09-04-2014, 01:52 AM #69

Junior Member

Junior Member

- Join Date

- May 2012

- Posts

- 67

Re: E/G CNC Mill

thewho,

Thanks for the quick reply. Would you be able to tell us how accurate your machine is (squareness, backlash, best tolerances held, circular interpolation, spindle tram etc..)? I watched your videos of your machine cutting steel, very impressive for a homemade machine! Nice work on that spindle, what is the max RPM you run? Does the spindle heat up? How about spindle lubrication, grease? Would you build a machine on a granite base again?

Thank you,

Phil

-

09-04-2014, 05:09 PM #70

Registered

Registered

- Join Date

- Mar 2008

- Posts

- 43

Re: E/G CNC Mill

I only used a 150mm angle when I assembled it, so precision is not top notch. But I didn't intend to make a super precision machine, in that case I would have gone to the bank and asked for a loan and then bought a vmc

I have .02-.03mm backlash so circles aren't exactly round if you know what I mean With Chinese rolled ballscrews and only one nut you really can't expect better results. I don't want to get bummed out so I've not measured anything since I built it.

With Chinese rolled ballscrews and only one nut you really can't expect better results. I don't want to get bummed out so I've not measured anything since I built it.

And in reality it does the things i mill good enough. If I had to mill a pocket for a bearing I would only rough cut it and then bore it out to size. Because you need a really good machine to make pockets good enough for a bearing.

I don't really have a max rpm. Just checked the bearings and they are apparently good for 11krpm. My spindle motor is 2800rpm @ 50Hz so in high gear (1:2) I have 5600 rpm at full power. I can speed it up but then I start loosing torque. I don't know how heat is affecting the spindle but at 7krpm it starts to heat up.

I really need to get that thing balanced though

I use a compressed air oiler (don't know the name in english) for the spindle bearing lubrication. But the airflow trough the spindle is too low so it dosn't work as intended

About the granite base: I think it's an awesome solution. Cheap and sturdy. (I got my base for free )

)

For the upcoming upgrades I plan to glue (epoxy) a thick steel plate to the granite. If all goes to plan I will get an accurate and sturdy base.

I'll also re-machine the column and fill it with epoxy and sand for vibration dampening.

Similar Threads

-

How to drill and face mill using table type horizontal boring mill

By SatishNaik in forum News AnnouncementsReplies: 0Last Post: 10-09-2013, 01:10 PM -

How boring, Face mill, End mill and Circular Interpolation done on Floor type HBM.

By SatishNaik in forum News AnnouncementsReplies: 0Last Post: 07-29-2013, 01:15 PM -

Home-Brewed CNC Bench Mill Using Siex X2 Mini-Mill Head

By fignoggle in forum Benchtop MachinesReplies: 18Last Post: 05-12-2009, 05:11 AM

Reply With Quote

Reply With Quote