Thanks for your reply,by appearance, I already known this.

Now I'm trying to estimate a little the cost before I start.

Can you share some calculation about this lovely machine? Such as the design target, ball screws and linear guideways selection, the precision grade and preload grade about them.and also the cutting force calculation which been used to decide the motor size and pitch of the screw.

I'm a mechanical engineer with less experiences, the design procedure is not very clear, but I really love mechanical things, I hope I can get your guiding.

Thanks in advance.

By the way, I had made one small 3 axis engraving machine, without calculation, it's work, but rough,bad looking ,bad precision.

Results 381 to 400 of 438

-

08-03-2013, 03:07 AM #381

Registered

Registered

- Join Date

- Dec 2009

- Posts

- 4

-

08-03-2013, 11:59 AM #382

Member

Member

- Join Date

- Jan 2007

- Posts

- 356

Well.. to be honest.. i didn't calculate anything..

i got some steppers from a friend of mine, and i designed the machine around those..

i bought new Bosch Ballscrews, highest precision, with preload.. since i intended this machine for precision fabrication of small parts, mainly for scalemodeling, but lately i ventured into watchmaking, for wich the machine is performing very well..

-

04-28-2014, 08:34 PM #383

Member

Member

- Join Date

- Jan 2007

- Posts

- 356

Re: My First CNC, own design, buidling in progress

It has been a while since i was here.. but.. i have been quite busy lately...

as i told before.. i'm into watchmaking.. made an aluminium Case for an old watch.. well that was just for "starters" nothing really worth showing or mentioning. but..

I Found my fathers first watch, it was broken.. so... indeed.. i opened the case.. saw what was wrong.. and ...

First.. i made a Movement holder. 2 pieces of aluminium, 2 pieces of brass rod, a piece of threade rod, a plastic knob.. and some milling.. that's all..

the movement in this holder is NOT the movement from my fathers watch.. although it is of the same model.. ETA 2763

This is the movement from my fathers watch.. it needed a new stem and crown.. and i took the movement apart to clean it..

From some left over Aluminium i made a new case as well.. as the original case was kinda damaged..

Then.. i made some hands... i milled these out of 0.20mm Brass sheet..

and from a piece of 0.3 mm Brass i made a dial..

And after drilling the lug-holes for the strap, and a hole for the stem and crown.. i painted the dial in a transparent red laquer.. pressed a crystal in to the case.. and.. Presto!..

this is just the beginning.. i'm thinking of starting my own company, building watches.. that's why i made another one..

The JHB Instrument 2

Specs:

Case Diameter: 42 mm

Lug-to Lug size: 47mm

Strap size: 22mm

Thickness: 9.85 mm

Sapphire Crystal

Swiss ETA 2763 Hand wound Movement 50 Hrs Power reserve, 21600 bph

Case Material: Titanium..

Yes.. indeed... the Beagle-1 VMC 2814 is capable of machining Titanium!...

-

05-03-2014, 10:13 AM #384

Member

Member

- Join Date

- May 2008

- Posts

- 1185

Re: My First CNC, own design, buidling in progress

I have always liked your work. The watch looks great. The outer housing turned out vary sharp.

youtube videos of the G0704 under the name arizonavideo99

-

05-03-2014, 04:28 PM #385

Registered

Registered

- Join Date

- Nov 2007

- Posts

- 2151

Re: My First CNC, own design, buidling in progress

Ditto!

For so many around here its all about production, feeds and speeds this is what I like.

this is what I like.

vflt's or very fine little things. Good name for a company btw.

Anyway nice work

md

-

05-03-2014, 06:30 PM #386

Gold Member

Gold Member

- Join Date

- May 2005

- Posts

- 3920

Re: My First CNC, own design, buidling in progress

Nice work!

To be honest I don't think I could ever make a living as a watchmaker, just a bit to ham fisted, so I can admire your abilities here. I say this with a bit of experience working on instruments at work which I find frustrating to say the least. It does give me a bit of perspective though when I see fine work like this.

As to the mill did you make any videos of the mill working on these various parts? I'd like to know how you held the hands for machining.

-

05-04-2014, 07:28 PM #387

Member

Member

- Join Date

- Jan 2007

- Posts

- 356

Re: My First CNC, own design, buidling in progress

Thanks.. originally i built the machine for making small and intricate parts for scalemodelling.. now i'm making watch parts.. same size, same accuracy, but now fully functional parts..

also . check out: www.facebook.com/jhbwatches

-

01-13-2015, 03:51 PM #388

Member

Member

- Join Date

- Jan 2007

- Posts

- 356

Re: My First CNC, own design, buidling in progress

At the moment i'm working on a batch of no less than 52 watches, the P1lot One..

This watch is a limited edition for a dutch watchforum, we formed a team of 5 designing the watch, making leather straps, and pouches, and we have a purchaser for all the parts we don't make ourselves

The P1lot One is really a top range watch, featuring:

Titanium Grade 5 Case

Titanium Grade 5 screw-back with sunburst pattern on the outside, Perlage pattern on the inside, and a laser engraving on the outside, with our logo, and the serial number

Synthetic Sapphire Crystal, with double sided anti-reflection coating

Brass Sandwich dial with Superluminova luminous material providing luminescense through the night..

ETA/Unitas 6498-1 Movement, elaboree, featuring côtes de Genève pattern on the bridges and Perlage on the main plate, 18000 beats per hour, 42 hours power reserve

Handmade leather strap/Olive Drab heavy-duty Nylon NATO strap

Springbar tool

Keychain

Certificate

and this is how it will look:

This is the Titanium Caseback

Every Caseback was centered on the Beagle VMC 2814 prior to milling the threads ( M39x0.5)

But, for the recessed Seconds Subdial i had to put in some manual work..

and this week.. i finally started on making the cases:

the Beagle handles this tough material great.. solid Carbide endmills do the trick, a smooth surface after milling so minimal finishing is required..saves me a lot of time..

Also... the leather strap will be fitted with a Titanium Buckle, grade 5 of course, and it will be laser engraved with a logo as well..

All in all.. a lot of work.. but.. i recently started my own company, and this is basically the first edition of watches that i'm building... hope to make some cash in the near future, to mount an ATC Spindle to the Beagle so i can machine more efectively.. i need to do a manual toolchange when milling the cases..

-

01-13-2015, 07:44 PM #389

Re: My First CNC, own design, buidling in progress

Miniature work! Looks really good!

-

01-13-2015, 09:13 PM #390

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 599

Re: My First CNC, own design, buidling in progress

Ziet er allemaal heel mooi uit! Mooi om een keertje weer een Nederlands achtertuintje te zien!

-

01-14-2015, 12:43 AM #391

Gold Member

Gold Member

- Join Date

- May 2005

- Posts

- 3920

Re: My First CNC, own design, buidling in progress

Very nice start here!

I'm hoping your will have a few videos posted to the net for the watch builds under your companies name. Done well they would be good marketing material. People that would go for a custom watch like this, would also like to show off how it was made or at least be interested in their own right.

-

01-14-2015, 03:51 AM #392

Member

Member

- Join Date

- Dec 2007

- Posts

- 2133

Re: My First CNC, own design, buidling in progress

Wow!

I'm a sucker for watches, that looks fantastic there Arie. I couldn't think of any finer thing to make.

More pics/videos please, I love watching the processes involved. On Youtube there's some great videos on Swiss watchmakers like George Daniels and others, absolutely fascinating stuff.

Great work.

cheers, IanIt's rumoured that everytime someone buys a TB6560 based board, an engineer cries!

-

01-14-2015, 03:18 PM #393

Member

Member

- Join Date

- Jan 2007

- Posts

- 356

Re: My First CNC, own design, buidling in progress

erhm.. Ian... George Daniels was no swiss watchmaker..

.. he was as English as horizontal rain...

.. he was as English as horizontal rain...

However, he was among the best watchmakers ever.. inventor of the coaxial escapement, now used by Omega..

I promise to make some video's in the future.. i do have some watchmaking vid's but those are shot on the Lathe..

Like this.. i bought two Emco Compact 5 CNC lathes.. one is churning out watchcases at the moment..

I still need to connect the toolchanger to the EdingCNC control.. and i have to build a toolchanger for the other.. but i've found a wormgear box of about the same size as the Emco Gearbox from the toolchanger..

if i make it to the same height, i can exchange toolplates.. always nice..

-

01-14-2015, 04:13 PM #394

Registered

Registered

- Join Date

- Jan 2007

- Posts

- 599

Re: My First CNC, own design, buidling in progress

How is the eding control working out for you? I have looked at it a couple of times. It looks nice but does it work well?

-

01-14-2015, 04:35 PM #395

Member

Member

- Join Date

- Jan 2007

- Posts

- 356

Re: My First CNC, own design, buidling in progress

well.. I'll shed some light on that.. in the next update..

-

01-14-2015, 06:22 PM #396

Member

Member

- Join Date

- Jan 2007

- Posts

- 356

Re: My First CNC, own design, buidling in progress

About EdingCNC..

When i started building this machine.. i didn't have any clue as to what software i was going to run on it..

I got the steppers and a PC from a friend who couldn't finish his CNC project..

That PC was running TurboCNC.. it might once, very long ago have been a reasonable CNC control.. but in my view?.. What a piece of JUNK.. Ok.. Now what.. the old PC could only run Windows 95 and DOS

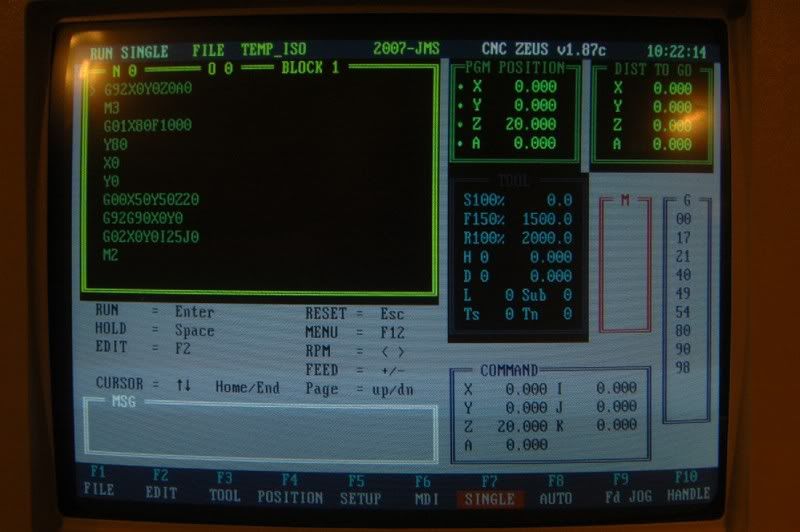

So.. i installed a Fresh version of both.. and i found ZeusCNC..Also a DOS Controller.. but it looked kinda familiar to me, it looked like an old CNC control.. and not a Dos-editor like environment like Turbo..

All functions in Zeus were controlled by F-Keys.. Great.. nothing really changed.. i was running a Bridgeport with a Heidenhain control daily at that moment in time.. so.. Zeus took little to get used to.. ..

The First software i ran... on the Beagle was Zeus... not bad.. not bad at all.. did what it had to do.. and it was easy to operate..

I ran Zeus for the first couple of months.. until...an event took place that changed it all. more about that in a next posting..

-

01-14-2015, 07:15 PM #397

Registered

Registered

- Join Date

- Mar 2004

- Posts

- 425

Re: My First CNC, own design, buidling in progress

Excellent thread, excellent work. Looking forward to a really good review of Edings product. From another thread of yours, it looks like you have been using it since 2007 ? I tend to like the GUI. Crisp, clean and no nonsense. Your earlier threads comments on Mach really hit home with me (I dont/cant bring myself to use it either).

Having recently retrofitted a similar sized lathe (Denford Orac), I'll be watching for your findings on toolchanger via Eding. It would be good for all to know what you had to do to accomplish it. I have the original Denford 8 position changer which works very well for me.... it is essentially the same internally as the Enco as I had one of those too, but sold it off for some extra cash.

Two final things...... What are you using for lathe CAM ?? and, If you are friends with Edings developer, suggest to him that if he was able to show the $ conversion rates right there on his products pages, I assure him he will sell more copies to people in the states. I THINK the basic usb control would cost only $250 in US dollars ? If so, that is an unbelievable bargain over what most people have been spending $150 on all these years.Chris L

-

01-14-2015, 10:49 PM #398

Member

Member

- Join Date

- Jan 2007

- Posts

- 356

Re: My First CNC, own design, buidling in progress

The "ZeusCNC" Era was in the first months of 2007.. i was at that time looking for a new PC, and some CNC software i could run in Windows, to ease the hassle of putting NC Files on the machine..

With Zeus i had to shut down the machine.. start up Windows, and by means of a file-transfer program, connect to my Psion Series 5 to get the NC Files on the machine... then.. reboot to DOS, and fire up Zeus.. to put it mildly... it worked.. but it SUCKED! big time..

So i went on the internet, and found this:

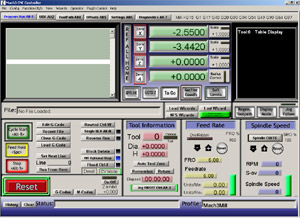

and i thought WTF!!

Because.. that's a lot of many buttons in my screen all of the sudden.. given the fact that i was used to

Good old Zeus..

Too many buttons on the Mach screen.. Too much Junk.. you got to have a mouse.. what have those guys been smoking when making that gui?.. my mother even thought i was Gambling online.... it does look like a slotmachine doesn't it?.. i just couldn't figure out how to operate it.. Mind you... as a professional toolmaker, i was running machines with Brother CNC controls, Mitsubishi, Heidenhain, and Fagor at the time.. all on a daily basis.. no problem whatsoever.. but Mach?.. i was utterly flabbergasted by the sheer number of buttons on the screen.. ..

and now.. i hear you mach users scream.. BUT!.. But... you can make your own screens!...

Yes indeed you can...

i mean.. DAYMN what has he been sniffing?.. but wait.. it gets even worse..

OMG!..

Well.. enough on the screens...

I stumbled upon damencnc.com - USBCNC and i read that in contrast to Mach, USBCNC offered smooth movement because of a CPU board that handled the timing, instead of leaving Windows to time everything...That was really the bottleneck of Mach in the beginning.. later on, Mach improved upon this.. but it would cause a high CPU load on the PC.. also something you don't want..

Smooth movement.. Ok.. i also found a clear sample of code.. and i was impressed by the opportunity of creating Parametric CNC Code.. since , at work, i already made a lot of parametric programs..

the only reservation i had, was the screen.. but one large.. no HUGE difference with Mach.. just a few buttons.. within 5 minutes i was familiar with the software..

Then.. on an annual meeting of the Dutch CNC forum, i met Bert Eding, the Author of USBCNC, he told me he develloped USBCNC because of the need for smooth movement, mach couldn't provide that then.. so he set out to avoid Windows timing, by building a CPU with a buffer and a timer of its own..

When i mentioned the layout of the screens.. he smiled and said.. at the time i made that screen.. i had no idea what a good screen needed to have.. so i just put in what i thought was needed.. and i've had no time to do anything with it.. but i'm planning on changing that in the near future..

I then told him i took a peek at Mach, and i didn't like what i saw.. and that i was working professionally with all kinds of CNC equipment..

Bert then asked me if i would like to help out designing the new layout of the screens..

after that meeting, I downloaded a VB.NET IDE.. to be able to design a new layout.. i'd make screendumps and describe how i thought it should operate.. and Bert made the Code to match it...

That is how we came up with the way EdingCNC/USBCNC looks now..

because i was working professionally with CNC, i knew some CNC controls.. and i noticed most of them were operated by means of softkeys... that was the first thing i suggested to Bert..

Over the last years things changed.. Customizable Icons on the buttons for instance.. although the current default icons are not too bad.. the first icons after the designing of the new Layout were.. erhm.. kinda "fisher-price". soft colours.. not really an industrial look.. but the default keys now have a nice industrial look althoug not yet fully compliant with the industry standard.. ah.. well.. most of it is just right..

To acces the menu's you just need to poke some F-Keys..I don't have a mouse attached to my machine, and i don't need one either.. i do have a touchpad on the mill, but use that rarely.. a Tab Key is just as easy to move through File dialogs..

on the Lathe, i have installed a Touchscreen.. works like a charm..

I will go into details about the functions and functionality in the next episode.. Stay tuned..

-

01-15-2015, 01:49 AM #399

Member

Member

- Join Date

- Dec 2007

- Posts

- 2133

Re: My First CNC, own design, buidling in progress

It's rumoured that everytime someone buys a TB6560 based board, an engineer cries!

-

01-15-2015, 12:13 PM #400

Member

Member

- Join Date

- Jan 2007

- Posts

- 356

Re: My First CNC, own design, buidling in progress

Ok.. As promised, a look into the details of EdingCNC..

Bert changed the name from USBCNC to EdingCNC, because he made a new type of CPU Board: not with USB Connection, but with an Ethernet Connection..this was the 5th CPU Board he made, Hence the name CPU5

I will not go into all specifications here, you can easily look that up yourselves at Eding CNC - PC based CNC control, but how does it work as a CNC control on a daily basis?..

Well, in my opinion, it works just great.. why?.. because of the User interface.. Ok.. i did design it.. but it still works and looks like a professional control..

One of the Coolest things is the Macro.cnc file, in this file the Toolchange routine is stored, as well as the homing routines.. you can change them if needed or desired..

I added a move after homing.. when the machine has homed all axes, it moves the table to the front, so i can put my parts on it..

Changing the toolchancge routine can enable you to automatically measure tool length after a toolchange.

At the moment, i don't have a toolsetter on the machine, but.. when i had one, when i changed tools, i measured the tool, so the machine knew what length it had.. only then... i would touch-off to set my workpiece zero.., when changing a tool after that?.. no more touching off.. no need to do so.. machine knows tool lengt... problem solved..

I made the toolchange and measuring routine myself.. but that toolmeasuring routine is now a standard part of EdingCNC, i was the first to use a toolsetter.. so there was no routine for it at that moment.. so it was up to me to write that.. as even Bert didn't have a toolsetter at that time..

Dialogs!.. those are Cool too.. imagine.. a CNC program becoming interactive!... by means of dialogs you can input numbers.. for instance.. the tool measurement routine... it has a dailog asking the approximate tool length.. this saves time, because the machine can do a rapid move to safetydistance, according to the value specified in the dialog..

also.. One could make parametric programs, for instance to mill out pockets.. or drill holes, or whatever you can think of.. and do that in a certain pattern.. if you know about programming... you could do all of that..

For the Milling machine, i wrote parametric subroutines.. and also put those in the Macro.cnc file, from MDI, or a loaded program, you can call these subroutines.. , so what i needed was only a program with parameters and a call (gosub) to the right subroutine from the Macro.cnc file.. well that was easy..

I wrote a VB.NET G-++ Code IDE, a program to write code for my CNC.. and i developped G++ a G-Code dialect for my machine.. My Programs mostly consist of Parameter definitions and subroutine calls.. i've made one subroutine in the Macro file, that looks at the value of one specific parameter.. and that's the one that tells the machine what sub to execute.. an identifier-parameter so to speak...

Later.. Bert Came up with a new command.. after Making DLGMSG ( DiaLoG MeSsaGe) he made LOGMSG, indeed.. you guessed it.. LOG message.. what does that do?.. well.. it enables you to write strings to another file.. and also values.. Ok.. strings and values?.. Riiiight.. you can indeed let EdingCNC create its own NC programs by first entering some values in a DLGMSG, and then write that to a file with LOGMSG.. how cool is that?.. well... le'me tell you.. that's very cool.. i have not yet adapted my macro file to use it on the mill.. but my lathe is running with this.. i can program an operation..and execute it

Because EdingCNC can automatically load a file at startup.. and reload when that file is changed.. the Values entered in the dialog when programming an operation ( like face-turning, Turning, Chamfering or filleting) are stored in the file loaded at startup.. it is therefore edited.. and automatically reloaded.. i get a preview on my screen to see what i have programmed.. if i like what i see..i hit the green button...

i don't use CAM software for the lathe.. and very little Cam for the mill... no need for that.. the only thing i use CAM for when making a watchcase.. is the shape of the case.. the rest is all programmed parametrically at the machine...

Similar Threads

-

more progress..

By adam_m in forum DIY CNC Router Table MachinesReplies: 0Last Post: 11-26-2013, 03:56 AM -

Design In Progress

By JoeDawg in forum Uncategorised MetalWorking MachinesReplies: 1Last Post: 10-07-2008, 07:48 PM -

My First Router Design & Progress

By watsonstudios in forum CNC Wood Router Project LogReplies: 40Last Post: 07-22-2007, 09:19 AM -

Looking into buidling an Auto-start RPC

By Wendell in forum Phase ConvertersReplies: 2Last Post: 10-12-2006, 03:03 AM -

Alibre design in progress

By xyzcnc in forum Uncategorised CAD DiscussionReplies: 10Last Post: 06-07-2005, 06:49 AM

Reply With Quote

Reply With Quote