Hi,

the steppers and drivers are fine, although I can't quite work out why you'd buy 80VDC capable drivers and run at less that that. Having said that a 60VDC

supply will be fine, just that an 80VDC supply would be better.

Motion control boards are what provide the pulse signal, usually via a breakout board, to the drivers which make the steppers run.

For the moment I'm going to exclude a PC driven parallel port....I may come back to that. PC's are not good at producing clean uninterrupted pulse streams,

they have so many things and multiple programs and processes going on that just cant stick to the one job of running your machine. For this reason motion control boards were

invented, the PC provides numeric trajectory data and the motion board turns that numeric data into stable, clean pulse streams. Typically they have a micro-controller IC

or an FPGA IC and even both. Because the hardware is dedicated to the one job, namely running your machine, it does the job well.

My Ethernet SmoothStepper motion control board is only about 4 inches square and runs of a 5VDC supply at about 100mA, hardly big power! It can generate pulse streams

up to 4Mhz, so really really fast. Additionally it can accept something like 30 digital inputs for things like limit switches and MPG pendants for manual jogging.

You can hook direct from the motion board to the stepper drives....but its better to hook it to a breakout board. The breakout board is usually small and cheap, it provides

some buffering, opto-isolation and convenient screw terminals for all the wires. They prevent cock-ups from blowing up your motion board. Its not so much a MUST HAVE

so much as its SO MUCH BLOODY BETTER TO HAVE.

As it turns out when I built my new mill I thought I'd make my own breakout board as well, that means I can exactly what I want and nothing that I don't, which is often the

problem if buying a commercial breakout board. I split it into two boards, the first board has 12 outputs, (10 for step/dir to five servos, one commoned ENABLE and one commoned

RESET) and five inputs (an ALARM input from each of the five servos). The second board has eight outputs (one for spindle ON/OFF and one for PWM for spindle speed, and six general

purpose) and 26 inputs. Because the servos are industrial the signaling is 24V, so I made all my inputs/outputs 24V tolerant.

I have two power supplies, a 5VDC 500mA supply for the motion board and part of the breakout board circuitry and a 24VDC 1A supply for the remaining circuitry for the breakout boards.

In the earliest days of hobby CNC Mach3 was able with some very clever software running alongside the Windows operating system allowed a parallel port to produce pulse steams

continuously. Because parallel ports were so common at the time it meant that anyone could get into CNC WITHOUT have to spend mega dollars on a controller. The popularity of Mach3

was established then......and is still popular today. The parallel port has its problems....its slow, 25kHz default and up to maybe 60kHz with SOME PCs, MUST be run on 32 bitPCs

with Windows 7 or Widows XP. IT WILL NOT RUN ON 64BIT or WINDOWS 10.

My advice is don't bother. You asked 'if there is a bottle neck', well there is and the parallel port is it...don't go there. If you want to run Mach, Mach4 preferred, then get an Ethernet SmoothStepper,

if you want to run UCCNC get a UC300...don't shag around with a parallel port.

There is one exception to that rule....LinuxCNC, a LinuxCNC driven parallel port can run quite fast and smooth. a parallel port is limited to 12 outputs and 5 inputs, enough for a basic machine

only. Somewhere is the region of 30-50 inputs and outputs is better.

The CNCDrive boards, like the UC100, UC300 etc can run either Mach OR UCCNC, but they are limited in speed, only 400kHz, whereas my Ethernet SmoothStepper can run at 4MHz..

When I run my servos flat stick (5000 rpm) with encoder resolution of 1000 pulse/per millimeter I need Step signals of 416kHz, the SmoothStepper can deliver easy whereas the UC300

cannot.

There are quite a few details to study and understand, the max pulse output speed is an example. You may not have been aware of it....until it snuck up and bit you on the ass.

Craig

Thread: Controller Advice Needed

Results 1 to 20 of 180

Hybrid View

-

11-30-2021, 09:18 AM #1

Member

Member

- Join Date

- Nov 2013

- Posts

- 4537

Re: Controller Advice Needed

-

11-30-2021, 10:51 PM #2

Member

Member

- Join Date

- Dec 2018

- Posts

- 112

Re: Controller Advice Needed

I totally missed the voltage rating of the motors. Didn't think of it for some reason. So that is a bottleneck. I chose these mainly because they are medium torque 23s with low inductance.

So I have spent the entire day so far re-researching the motor/driver/PS options. It is very hard to find the sweet spot where all the components match up the way you want (within a budget). If money was no object then I am sure it would be easier. So I ended up down this HUGE rabbit hole of Closed Loop (Hybrid) Nema Motors. From all that I have read and my little to no understanding these look like a step up from the open loop options. I have done the math and for just a few dollars more I can into a closed loop setup (vs the components I had already chosen). My question is will this closed loop setup perform better than the what I had already chosen?

Open Loop

Nema 23s (400oz.in/1.8mH/5.6amps) - Specs

DM860 Stepper Motor Driver 2.4-7.2A/36-110VDC - Specs

AC to DC 60V 16.7A 1000W Switching Power Supply - Specs

Closed Loop

Nema 24 Closed Loop Stepper Motor (3.0Nm/424.92oz.in/1.8mH/5amps) Encoder 1000CPR - Specs

Closed Loop Stepper Driver 0-8.0A/24-48VDC - Specs

AC to DC 48V 20.8A 1000W Switching Power Supply - Specs

I don't think there is much of a bottleneck with this closed loop setup. The max volts is 48V and the amps are 5A. So I think the PS is matched up better than the open loop. Please point out any misunderstandings/mis-information you can see. It is my understanding that a setup that is matched well will outperform one that is not, even with less powerful motors in some cases. These closed loop motors have a 1.8mH inductance as well.

If I end up going this route I will need to figure out either how to mount the Nema 24 on my Z-axis that has a Nema 23 mount or maybe I just swap out one of the Nema 24s with a 23.

I know the closed loop setup does not have the potential (future proofing/growth) the open loop does, but I just want a good solid performer that will cut wood, plastic, aluminum without to many issues/bottlenecks. I also have read all the performance advantages that the closed loop offers over the open loop as well and I think that more than makes up for the lack of growth potential. Provided this will do what I need for now.

Alright now back to the rest of your post. GREAT info! Exactly what I needed to know. Going to start looking into all that info.

-

12-02-2021, 12:42 PM #3

Registered

Registered

- Join Date

- Jan 2018

- Posts

- 1516

Re: Controller Advice Needed

The 60v setup will likely have a slightly higher max velocity potential.

24's fit on 23 mountings.

As Craig says. Closed loop steppers can be a bit of a red herring.

For true closed loop, servos are the way to go.

However. A respected router builder here in u.k. (commercial & hobby) highly rates the Lichuan LCDA86H & LC60H2102 combination for closed loop steppers.

Mostly on 2m+ size builds.

Lichuan LC60H286 motors are a better fit for hobby units imho. But...

.... With resistance of 0.5, induct of only 1.3, torque of 3NM, at only 4.5A........ They're not exactly cheap.

-

12-02-2021, 08:58 PM #4

Member

Member

- Join Date

- Dec 2018

- Posts

- 112

Re: Controller Advice Needed

I was wondering about that. I think I have seen mounts that are for 23/24s.

I know servos are the way to go but unfortunately they are no longer in my price range. I guess I was hoping that the hybrid closed loop setups were a step up and offered some added protections/features. So all the hype is just marketing rhetoric?

I will look into these but it sounds like they are not in my budget.

Thanks

-

12-10-2021, 08:09 PM #5

Registered

Registered

- Join Date

- Mar 2017

- Posts

- 926

Re: Controller Advice Needed

Nema 24 do not fit nema 23 mounts. I used NSK linear actuators for my first build and they came with Nema 24 Yaskawa AC servos.

It was really annoying because I couldn't simply drill new holes for the Nema 23 motors because they were too close to the nema 24 holes.

It's one of the reasons I switched to the 465 oz in nema 34 3.5amp motors.

I'm glad I went with the 34's though because they have a 1/2" shaft which is considerably more robust and easier to mount (as they're longer) than the 1/4" shaft on my 23's.

A twig-thin shaft is definitely a source of weakness in the drive. If you go with 23's, I'd suggest going with the 3/8" shaft versions as a minimum.

-

12-10-2021, 09:20 PM #6

Member

Member

- Join Date

- Nov 2013

- Posts

- 4537

Re: Controller Advice Needed

Hi,

'The good thing about standards is....there is so many to choose from'

Craig

-

12-10-2021, 10:43 PM #7

Registered

Registered

- Join Date

- Jan 2018

- Posts

- 1516

-

12-10-2021, 11:00 PM #8

Member

Member

- Join Date

- Nov 2013

- Posts

- 4537

Re: Controller Advice Needed

Hi,

whether we like it or not the largest share (75% plus) of CNC components are metric.

Japan=metric

Europe=metric

China=metric.......and the Chinese do the manufacturing for so many companies from all over the world, so even if the 'company' is US say, the actual product is made in China often to metric standards.

If you restrict yourself to those manufacturers that stick strictly to NEMA sizes, well the good news is that there are plenty of them, US made in the main. The bad news is that they tend

to be over-priced, and more often than not under-perform.

If want the widest range of products from the widest range of manufacturers to secure the best price/performance trade-off then metric is the best choice.

Craig

-

12-11-2021, 11:54 PM #9

Member

Member

- Join Date

- Dec 2018

- Posts

- 112

Re: Controller Advice Needed

Yeah I was very disappointed when I went to order my Nema 23s to find that they are 6.35mm instead of 8mm like many Nema 23s. I was hoping to go with the 24s because the ones I were looking at were 10mm but in the end they would not have worked in my setup. So I am sure that I will be upgrading the motors in the future.

All comes down to budget, and I blew way past mine. So I will have to make it work for a while.

I did end up getting the 2 disc/diaphragm couplings instead of the spiral kind.

-

12-12-2021, 01:44 AM #10

Registered

Registered

- Join Date

- Jan 2018

- Posts

- 1516

Re: Controller Advice Needed

Pity about the shaft size.

As long as you get it in level it shouldn't be too much issue. Mainly keep an eye out for any coupling slip.

If you want to get decent performance the initial budget always goes out the window.

I assume it is the motors you need to wire in parallel to get the best results.

-

12-03-2021, 12:24 PM #11

Registered

Registered

- Join Date

- Jan 2018

- Posts

- 1516

Re: Controller Advice Needed

I see no reason why something like this wouldn't work well together from a laptop and Linux.

To give you 16 outputs, 18 inputs from ucbb bob dedicated for step/dir / limits etc.

Use 5 axis bob as 12 out 5 in dedicated to run spindle controls- pwm / relays / sensors etc.

Basically works similar to me unning my UC300eth for uccnc. I can use ANY breakout board with it on it's output based ports.

With Linux I think you can choose whether a port is in or out based.... Correct?.

7I98: Ethernet.

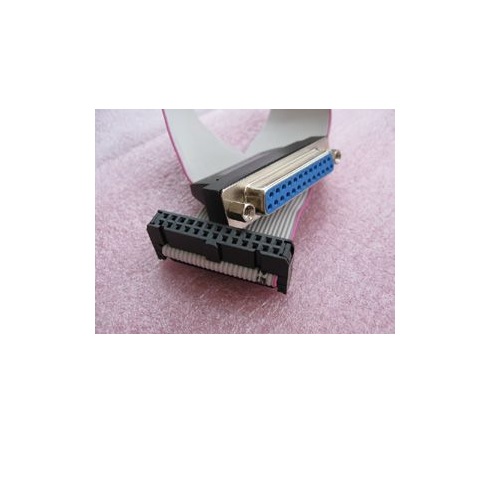

7I98 picture

A UCBB

https://www.cncdrive.com/UCBB.html

5 axis bob (+idc-db cable).

-

12-03-2021, 08:48 PM #12

Member

Member

- Join Date

- Dec 2018

- Posts

- 112

Re: Controller Advice Needed

Just so I am understanding how these go together and what their purpose/job is.

- So the UCBB (2 cables) and the 5 axis BOB (1 cable) would plug into the 3 plugs on the 7i98?

- I am a little confused on why I need all these added boards. Can you clarify the purpose of each?

I thought/hoped that Mesa would have one ethernet board that goes between LinuxCNC and the stepper drivers and misc sensors/relays. Adding all these boards we are up in the $250-300. That is a lot more than I expected, especially when the motion controller (LinuxCNC) is free. Maybe this is not the most cost effective way to go like I thought.

Would something like the Mesa 7I96 STEP/IO Step & dir plus I/O daughtercard do what I need?

-

12-03-2021, 10:37 PM #13

Registered

Registered

- Join Date

- Jan 2018

- Posts

- 1516

Re: Controller Advice Needed

I was mainly demonstrating what could be achieved as you gradually build it up.

The amount of IO avalable can bring options for more axis, ATC, cooling/vacumn/air relays, encoders and so forth.

Basic 4 axis and spindle may just need the mesa and that cheap 5 axis bob to keep things compact.

However..... That ucbb board I mentioned has really fast optocouplers that can handle high khz rates.

-

12-03-2021, 11:04 PM #14

Member

Member

- Join Date

- Nov 2013

- Posts

- 4537

Re: Controller Advice Needed

Hi,

But you don't need the BoB, the specs clearly say the the required buffering, optoisolation and screw terminal are built in. You don't need ANY extras.and that cheap 5 axis bob to keep things compact.

Craig

-

12-03-2021, 11:44 PM #15

Member

Member

- Join Date

- Dec 2018

- Posts

- 112

Similar Threads

-

Controller Advice needed

By robwiacek in forum Servo Motors / DrivesReplies: 0Last Post: 01-05-2018, 01:34 AM -

Advice Needed servo drives and controller software

By Krebomatix in forum Servo Motors / DrivesReplies: 0Last Post: 09-10-2017, 08:01 AM -

[ADVICE NEEDED] Z-Axis not moving - CNC builder needed

By baodogg in forum Australia, New Zealand Club HouseReplies: 2Last Post: 06-03-2014, 12:42 PM -

Material advice and advice needed

By kiyoukan in forum Mechanical Calculations/Engineering DesignReplies: 0Last Post: 02-15-2012, 08:20 PM -

CNC Controller Advice Needed For homemade cnc mill

By crashing in forum CNC Machine Related ElectronicsReplies: 2Last Post: 06-26-2010, 09:12 PM

Reply With Quote

Reply With Quote