Hi Mogi - So you want an extremely heavy machine? The mass is great argument I don't agree with. But set a course and in a couple of weeks or a couple of years you will find out if its the right one. 400kg of concrete for no good reason is strange to me. Think about this. The concrete is not in the loadpath from tool to structure. The loadpath goes thru the steel bed to the bolts holding it to the frame which is all steel. Steel is 200GPa stiffness and concrete is 40GPa so the load travel's thru the stiffest medium which is the steel. So the concrete just adds weight. So sensible design of the base in steel will be better. If concrete is cheap then make a cast machine base in concrete then you have a damper, potentially stiffer lighter structure then a space frame. Then extend that to a cast gantry....But do some FE to sort that out.

Plus concrete and steel have a bond strength in the order of <1.0MPa so I believe its a never bond situation. That's a strong reason LM have gone to EG in my view. Epoxy is known to stick to steel really well... Peter

Results 1 to 20 of 160

Hybrid View

-

03-17-2023, 06:50 AM #1

Member

Member

- Join Date

- Jul 2018

- Posts

- 6492

Re: Gantry 3-axis milling machine Design preparation phase

-

03-17-2023, 08:24 AM #2

Member

Member

- Join Date

- Feb 2023

- Posts

- 66

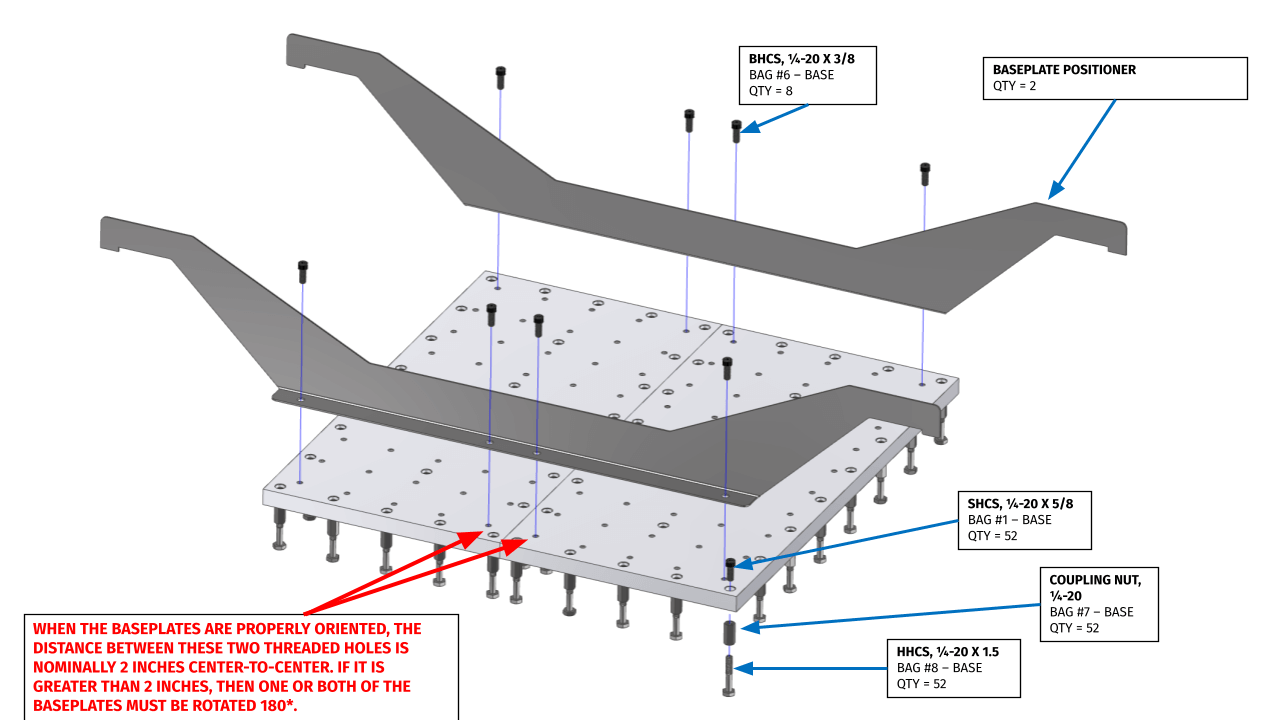

Hi Peter langmuir design loadpath goes thru to steel bed to the almost 40 bolts acting as rebar then to concrete

So what is connecting the steel bed to the machine rails is the concrete as you see in the image, is this a good design ?

After the concrete there is a layer of epoxy to close all the tiny holes and prevent any liquid from effecting the concrete

Also why i need mass because the gantry and z can weight about 200kg depends on the design I will go with. So to have that much weight moving to stop it need heavy base so the machine don't fly off the ground.

Reply With Quote

Reply With Quote